Multi-row strip sowing seed flow adjustable sowing assembly

A flow and strip technology, applied in the direction of sowing seeders, planter parts, etc., can solve the problems of difficult and consistent adjustment accuracy, low efficiency, cumbersome adjustment operations, etc., to achieve good consistency of adjustment accuracy, unique structure, and adjustment efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

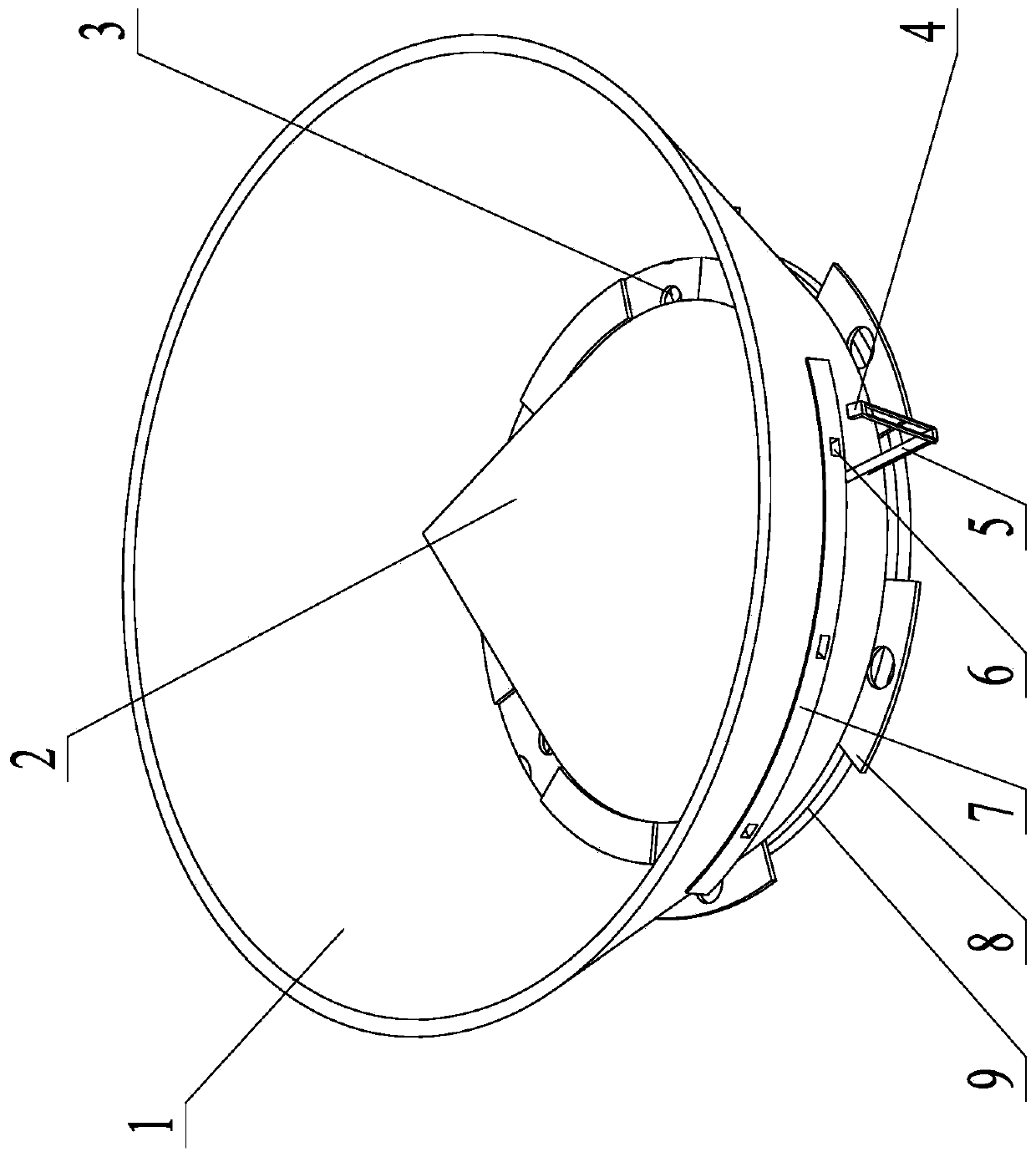

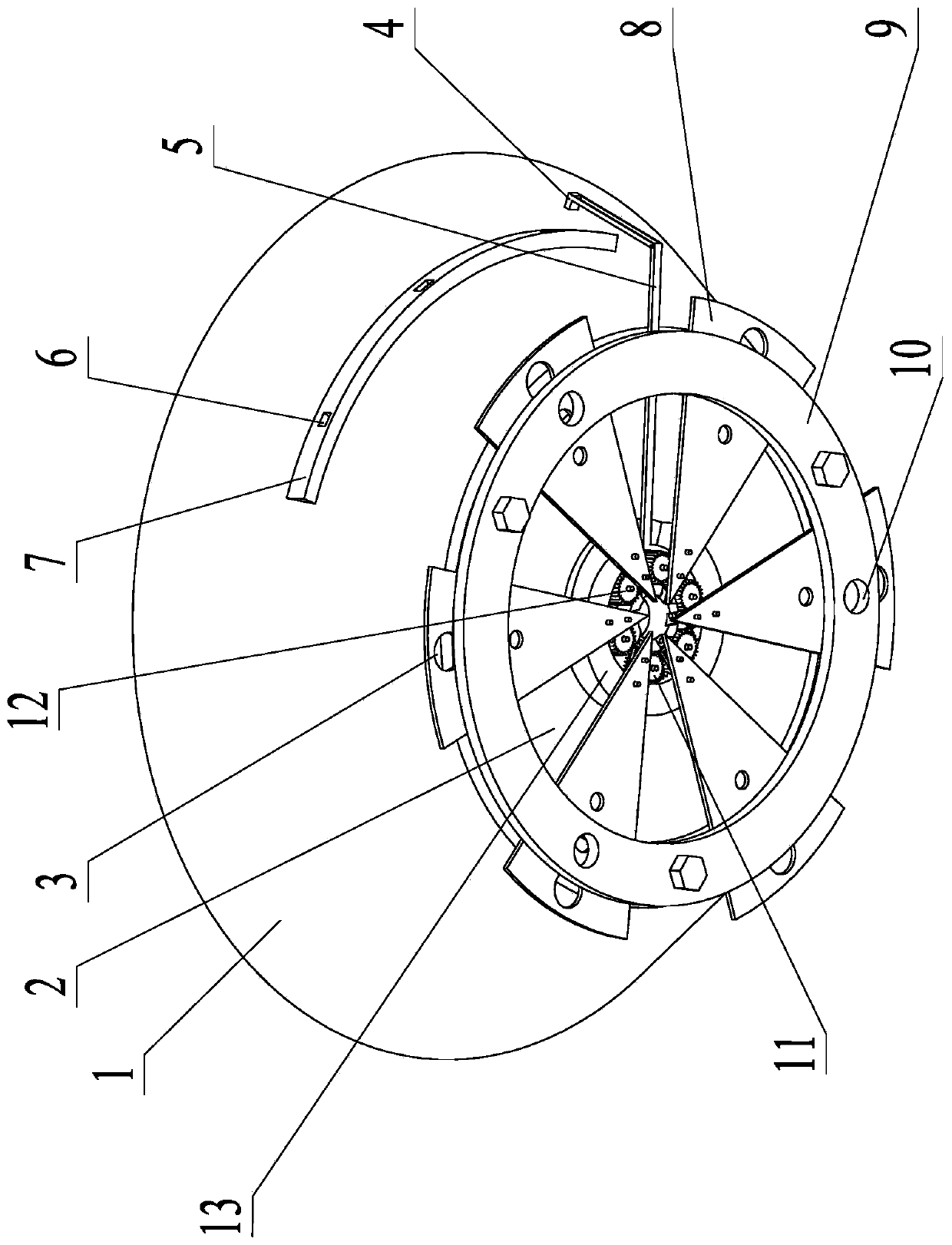

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A multi-row sowing assembly with adjustable grain flow, in which a conical seed distribution body 2 is fixed on the inner lower part of a conical funnel-shaped seed box 1, and is coaxially fixed on the outside of the bottom end of the conical seed distribution body 2 The circular inner seat plate 13 is installed, and the inner ring gear 14 is fitted concentrically on the circular inner seat plate 13 and can rotate reciprocatingly along the circumferential direction. On the circular inner seat plate 13, the inner tooth N pin shafts 12 are evenly distributed along the circumferential direction at the inner side of the ring 14, and the cylindrical gear 11 is rotatably sleeved on the pin shafts 12. N racks 15 are installed reciprocatingly, and the cylindrical gears 11 are meshed with the ring gear 14 and the rack 15 respectively, and fan-shaped blades 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com