Partial pressure watering device for greenhouse planting

The technology of a sprinkler device and a shed body is applied in the directions of fertilization device, liquid fertilizer distribution, and pressure spreading method of liquid fertilizer. The effect of irrigation and watering is even and thorough, and the overall design is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

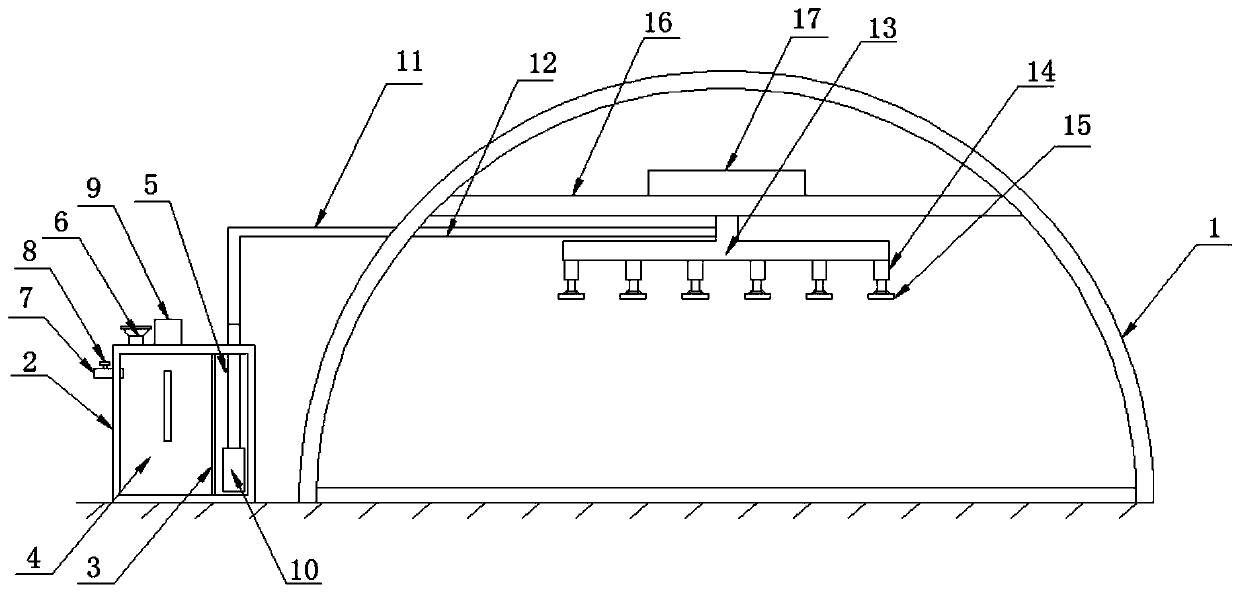

[0028] Such as Figure 1-3 As shown, a greenhouse planting partial pressure sprinkler device according to an embodiment of the present invention includes a shed body 1, a water storage tank 2 is provided on one side of the shed body 1, and the water storage tank 2 is a cavity structure. A vertical sieve plate 3 is provided in the cavity of the water storage tank 2, and a chamber one 4 and a chamber two 5 are respectively formed between the sieve plate 3 and the water storage tank 2, and the chamber one The top of 4 is provided with feeding port 6, and described feeding port 6 is connected with described chamber one 4, and the top side of described chamber one 4 is provided with water inlet pipe 7, and described water inlet pipe 7 is provided with valve 8. The first chamber 4 is provided with a stirring mechanism 9, and the bottom of the second chamber 5 is provided with a water pump 10, and the output end of the water pump 10 runs through the inner wall of the second chamber 5...

Embodiment 2

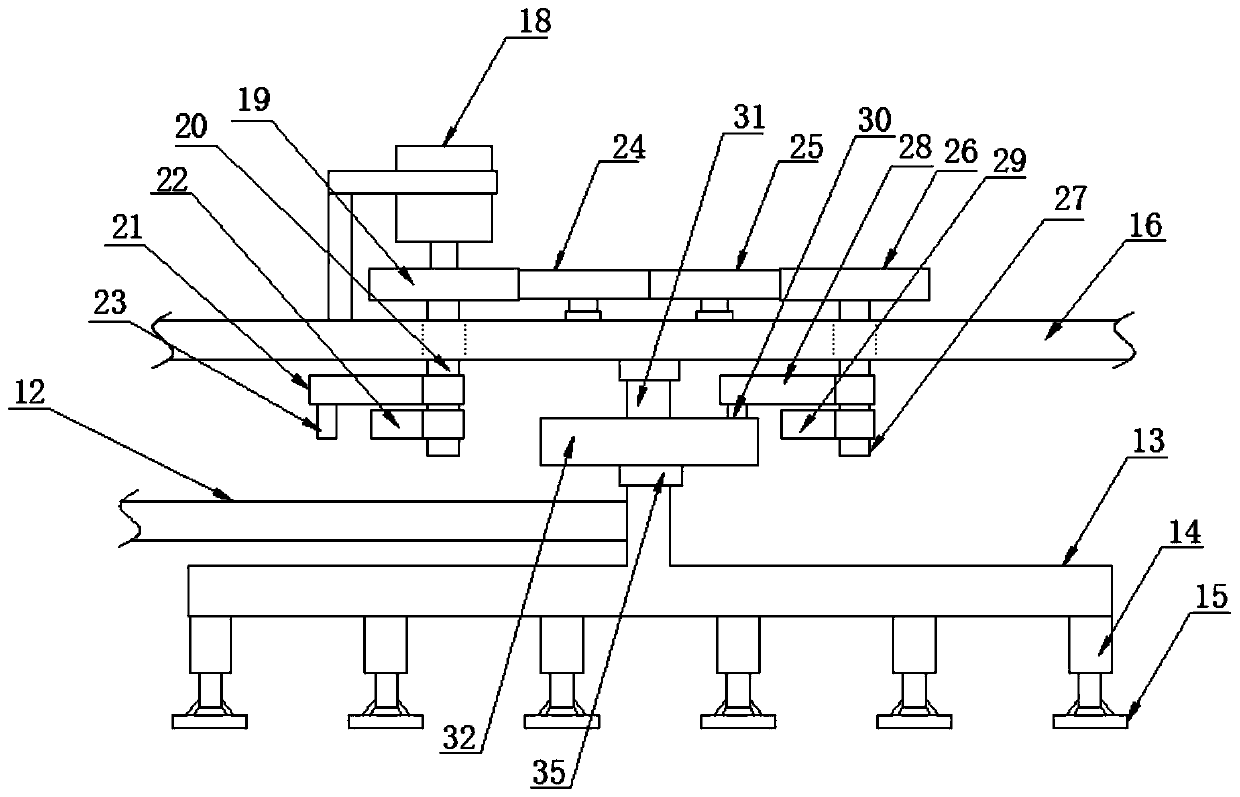

[0031] Such as figure 2 As shown, the tooth width, addendum circle diameter and modulus of the second gear 24 and the third gear 25 are the same.

[0032] Such as figure 2 As shown, the tooth width, addendum circle diameter and modulus of the first gear 19 and the fourth gear 26 are the same.

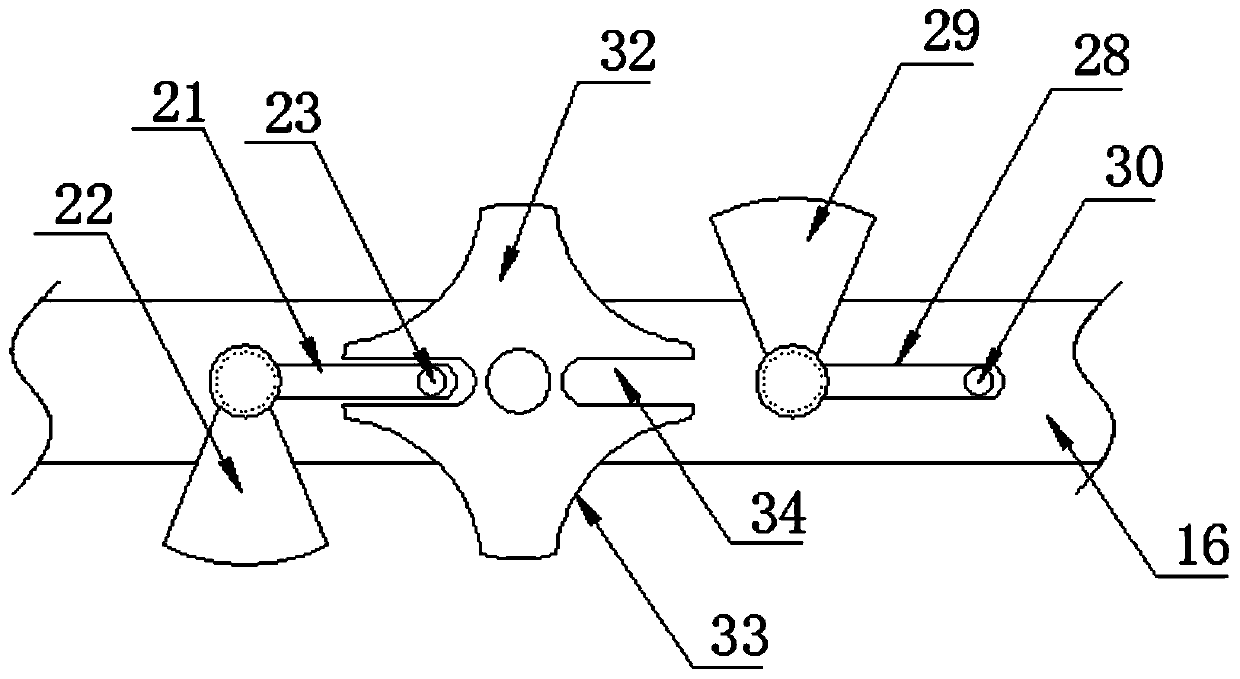

[0033] Such as figure 2 , image 3 As shown, the first arc block 22 and the second arc block 29 are adapted to the arc groove 33, and the first pin 23 and the second pin 30 are compatible with the limiting groove 34. adaptation.

[0034] Such as figure 1 As shown, the feeding port 6 is provided with a cover. Thereby avoid impurity to enter in the water storage tank 2. In practical applications, a sealing ring may be arranged in the above-mentioned cover.

[0035] Such as figure 2 As shown, the first rotary motor 18 is provided with a fixing frame, and the bottom end of the fixing frame is connected with the installation plate 16 . Thereby, the stability of the rotary elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com