Multifunctional down jacket for outdoor sports

A multi-functional technology for down jackets, applied in the field of down jackets, can solve the problems of easy movement and agglomeration of down, and achieve the effect of avoiding running down and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A multifunctional down jacket for outdoor sports, comprising a down jacket main body, the down jacket main body is sewn from a surface layer and down material, and the down material is made of artificial down produced by feathering;

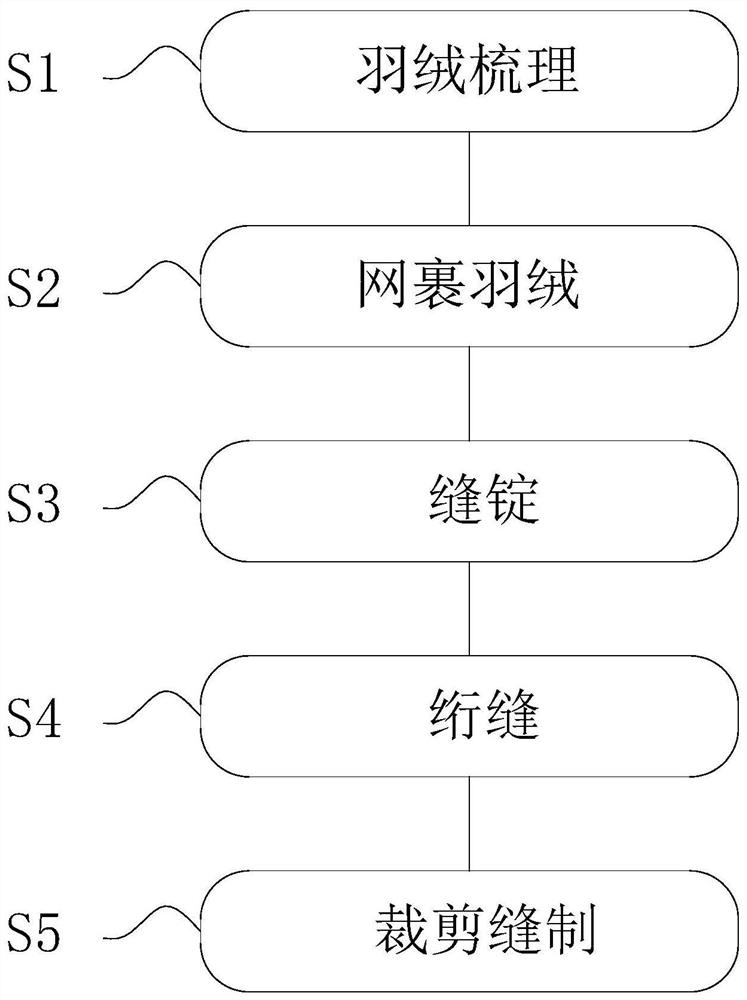

[0038] Such as figure 1 Shown, a kind of processing method of outdoor sports multifunctional down jacket, comprises the following steps:

[0039] Step S1, down carding; fluffing and carding the artificial down;

[0040] Step S2, net wrapping down; laying the bottom net body on the processing platform, then laying the fluffy and carded artificial down on the bottom net body in step S1, and covering the top layer of artificial down on the top surface The net body, and then the artificial down and the net body on the bottom layer and the top layer are punctured into one by the needle punching machine, and the roll-shaped net-wrapped down is obtained by winding;

[0041] Step S3, sewing ingots; sewing the net-wrapped down in step S2 on both ...

Embodiment 2

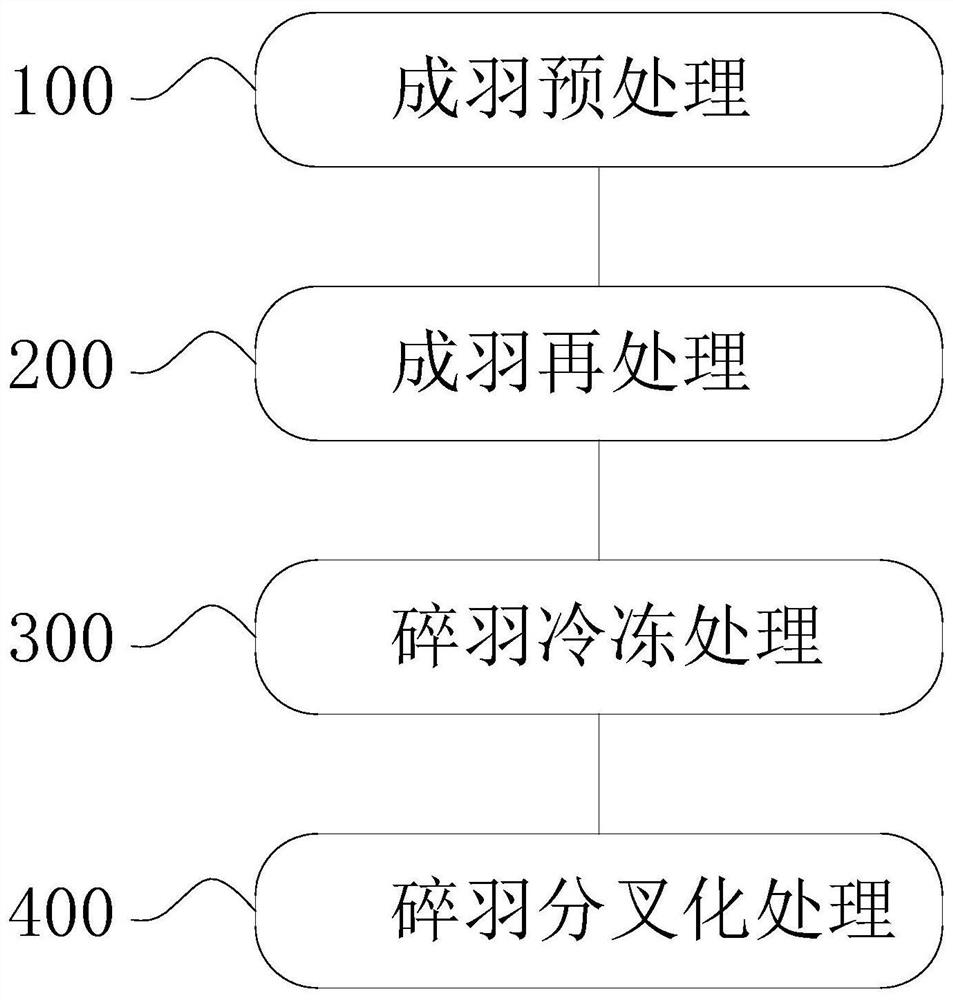

[0059] A method for preparing artificial down for outdoor sports multifunctional down jacket, comprising the following steps:

[0060] Step 100, pretreatment of adult feathers; removing the adult feathers of geese and ducks, cleaning and drying;

[0061] Step 200, the adult feathers are reprocessed; the adult feathers cleaned and dried in step 100 are cut off the quills to obtain broken feathers;

[0062] Step 300, freezing treatment of crushed feathers; adding water to the crushed feathers in step 200, then freezing at -10°C for 31 minutes, and thawing at 30°C for 31 minutes after freezing, and thawing the crushed feathers drying;

[0063] Step 400, bifurcate the broken feathers; add the broken feathers after thawing and drying in step 300 to a sealed mixing tank for stirring, add abrasive materials into the stirring tank during stirring, take out and dry after stirring for 21 minutes to obtain artificial down;

[0064] The abrasive is a mixture of ice particles and dry ice...

Embodiment 3

[0067] A method for preparing artificial down for outdoor sports multifunctional down jacket, comprising the following steps:

[0068] Step 100, pretreatment of adult feathers; removing the adult feathers of geese and ducks, cleaning and drying;

[0069] Step 200, the adult feathers are reprocessed; the adult feathers cleaned and dried in step 100 are cut off the quills to obtain broken feathers;

[0070] Step 300, freezing treatment of crushed feathers; adding water to the crushed feathers in step 200, then freezing at -10°C for 32 minutes, and thawing at 30°C for 32 minutes after freezing, and thawing the crushed feathers drying;

[0071] Step 400, bifurcate the broken feathers; add the broken feathers after thawing and drying in step 300 to a sealed mixing tank for stirring, add abrasive materials into the stirring tank during stirring, take out and dry after stirring for 22 minutes to obtain artificial down;

[0072] The abrasive is a mixture of ice particles and dry ice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com