Machining method for specially-shaped thin-wall shell body part

A thin-walled shell and parts processing technology, applied in the field of parts cutting, can solve the problems of easy vibration and deformation, achieve the effect of convenient clamping, prevent parts deformation, and save the production of special tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

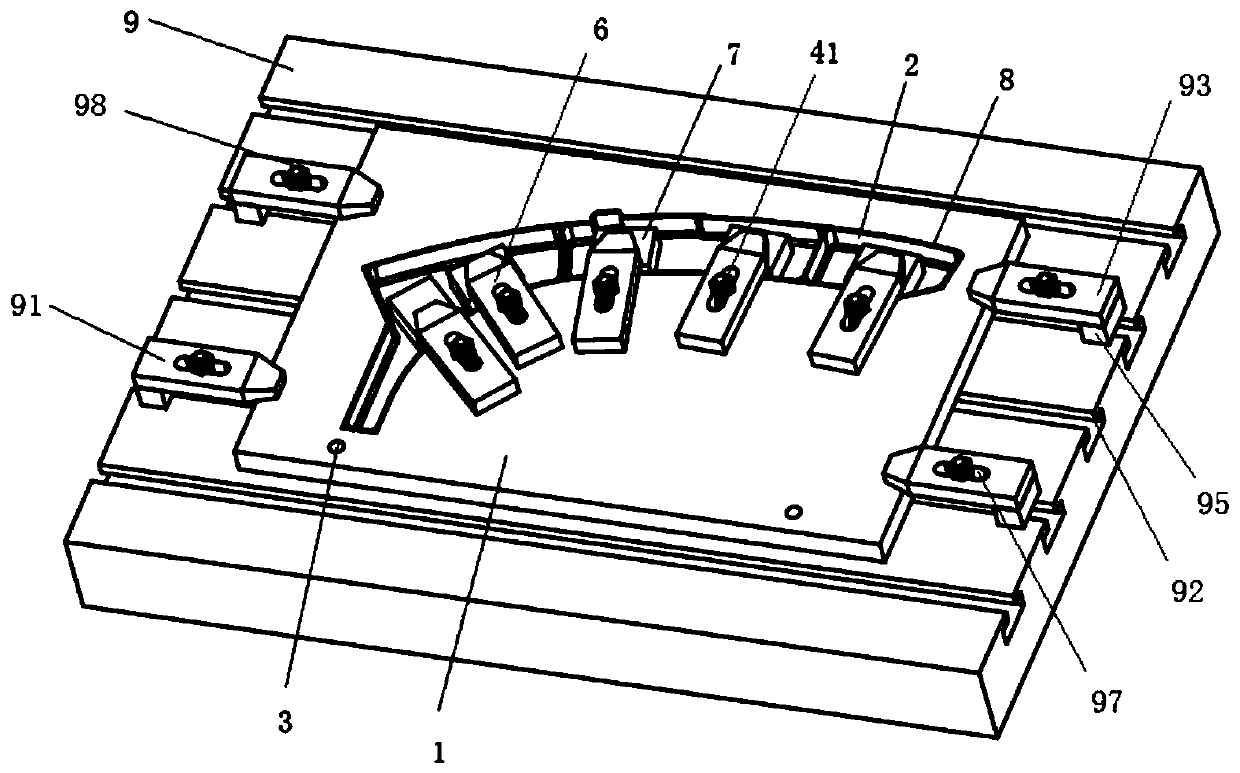

[0031] A method for processing special-shaped thin-walled shell parts, including several steps of plate preparation, rough milling, alignment, aging treatment, finishing cavity end face, finishing milling bottom surface and shape, finishing cavity and removing blank, the specific steps are as follows :

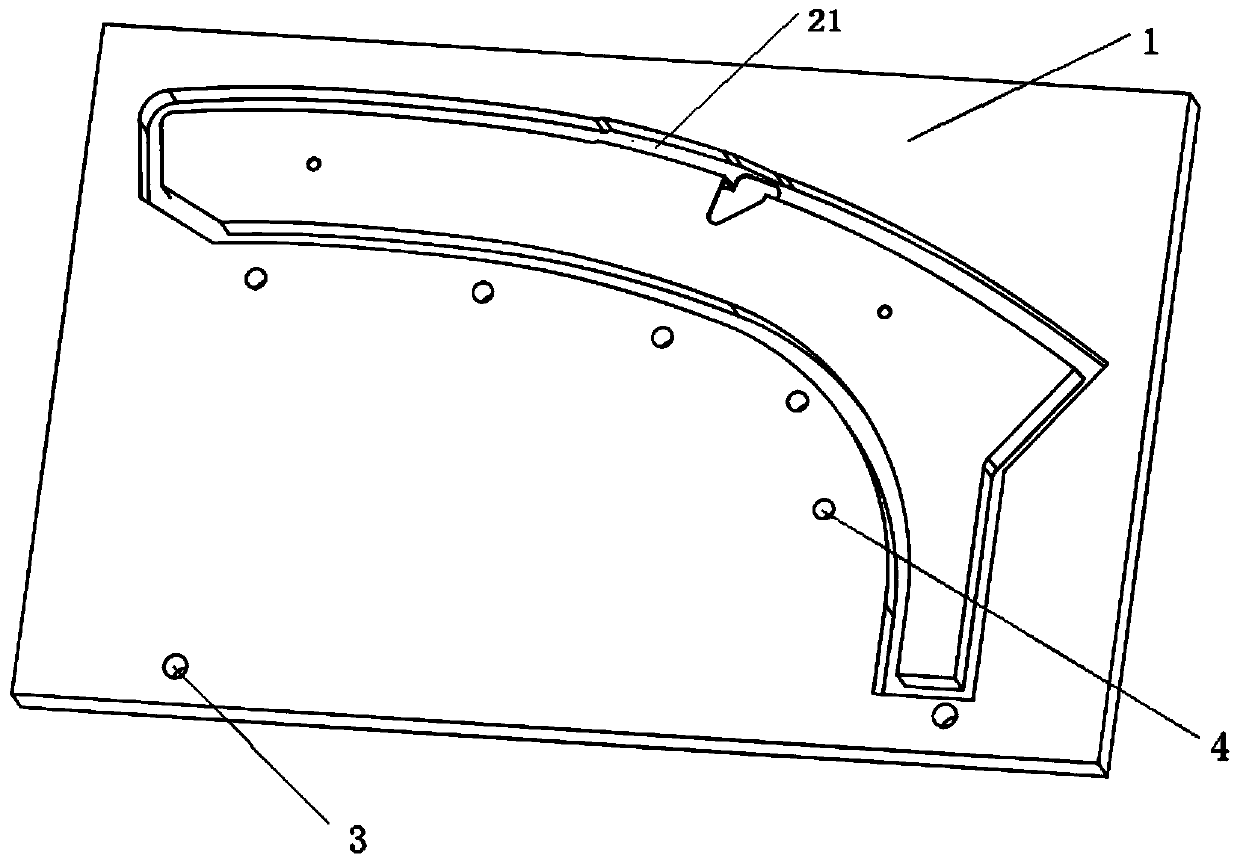

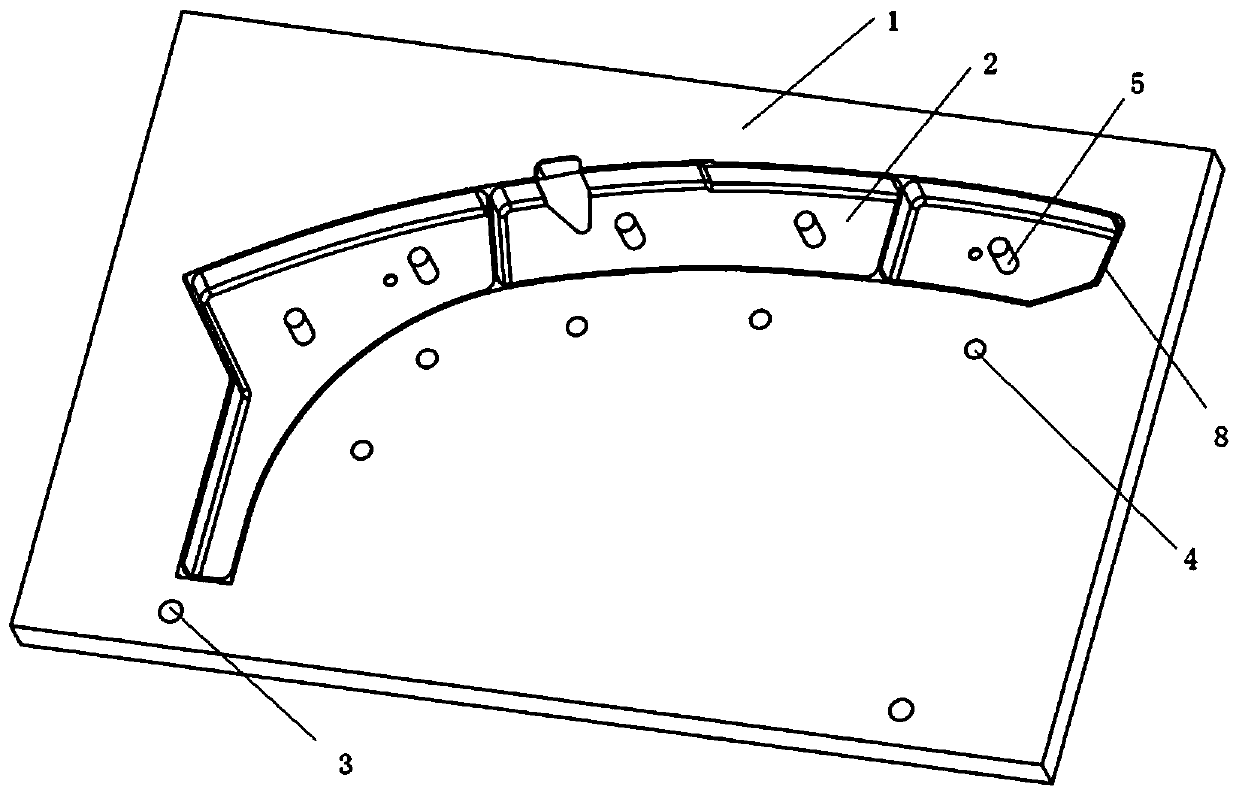

[0032] S1. Spare board: Select a square board 1 with regular shape, thickness and appropriate size according to the parts selection. The material thickness of the square board 1 is at least 5mm greater than the thickness of the part, and the length and width of each side are at least 40mm greater than the length and width of the part; that is, first supplement the special shape It is square; it is convenient for clamping, alignment, and strength in subsequent processing, saving special tooling.

[0033] S2. Rough milling: Roughly mill the ring groove 21 of the contour shape of the part on the square plate 1 to release the stress and prevent the deformation of the part after fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com