Structure with boss capable of assembling soft ring and aluminum plastic combined water cover

A soft ring aluminum and water cap technology, applied in the field of bottle cap processing equipment in the packaging industry, can solve the problems of low assembly efficiency, high labor intensity and high production cost, improve production efficiency and product quality, ensure product supply, reduce The effect of labor intensity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] For better understanding and implementation, the present invention will be further described below in conjunction with accompanying drawing:

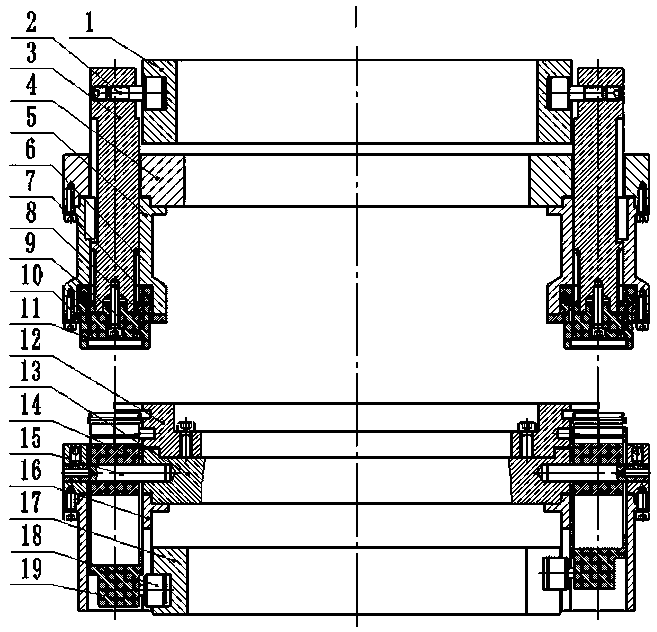

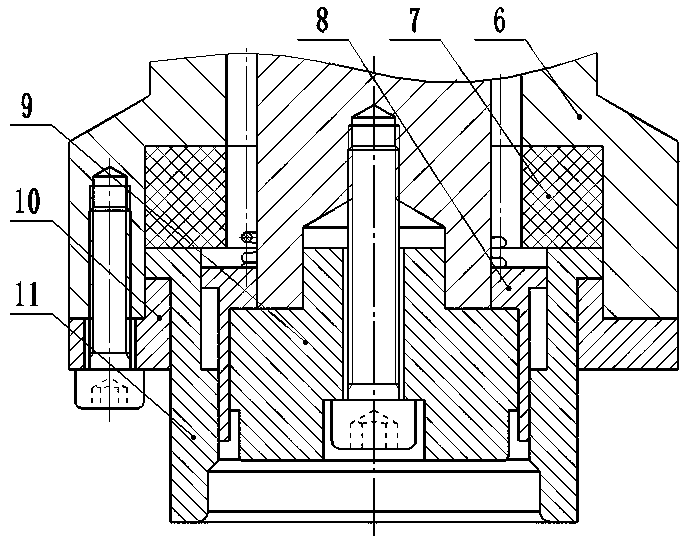

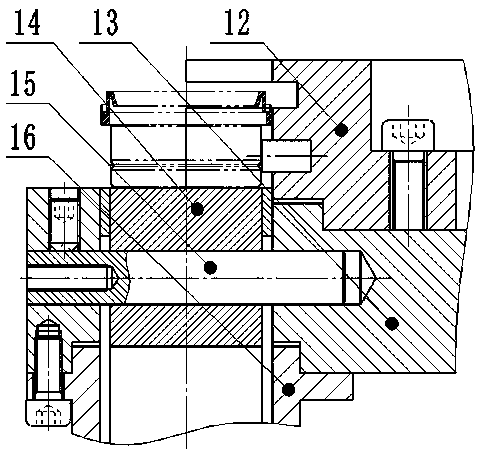

[0015] An aluminum-plastic composite water cover with a boss soft ring can realize continuous assembly structure, mainly including a forming cam 1, a forming rotating plate 4, a positioning rotating plate 13, and a positioning cam 17, and is characterized in that the forming rotating plate 4 is equipped with There is a forming guide sleeve 5, the inner hole of the forming guide sleeve 5 is provided with a forming rod 3, the upper end of the forming rod 3 is provided with an inner positioning head 9 to connect the forming pin 2, and the guide wheel of the forming pin 2 is in the cam groove of the forming cam 1 ; The upper end surface of the positioning rotating plate 13 is provided with a receiving tray 12, the lower end surface is provided with a positioning guide sleeve 16, the cam groove of the positioning cam 17 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com