Preparation method of energy-saving thermal-insulation foamed rubber for PPR pipe

A technology of foam rubber and heat preservation, applied in the field of rubber, can solve the problems of high thermal conductivity, heat loss, low tensile strength, etc., achieve high wear resistance, increase heat insulation efficiency, and improve the effect of overall heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

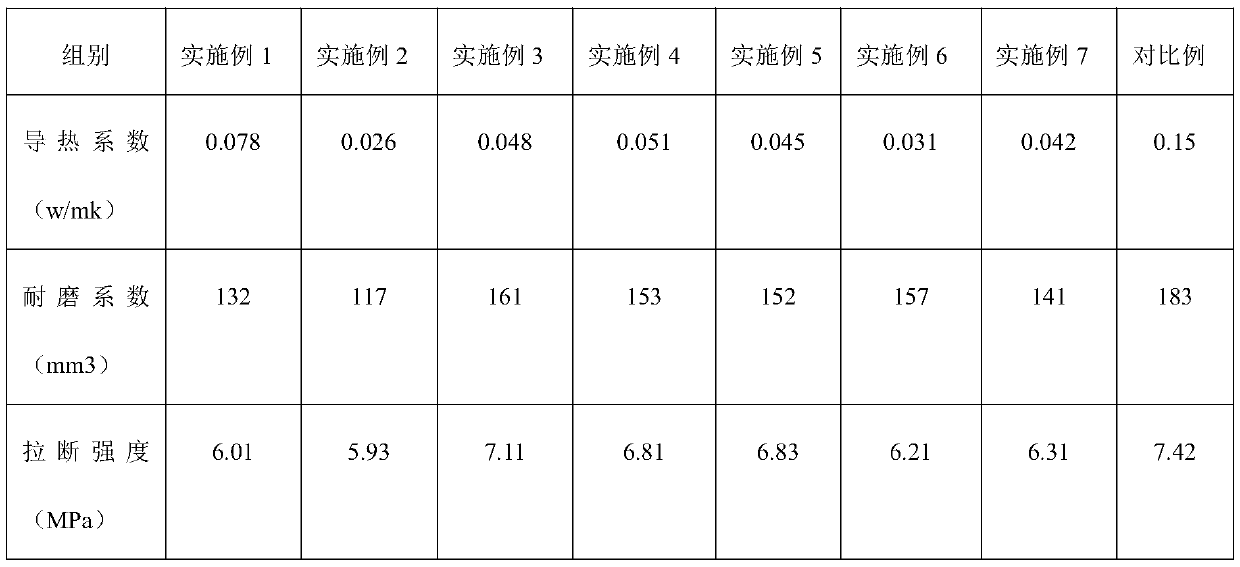

Examples

Example Embodiment

[0030] Example 1

[0031] 1) Weigh 3g of triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene and add it to the hydrochloric acid solution with a concentration of 0.001mol·L-1, and stir until the triblock copolymer polyoxyethylene-polyoxypropylene -Polyoxyethylene is completely dissolved;

[0032] 2) Add 2 mL of methyl orthosilicate to the solution obtained in step 1, and stir for 4 hours until methyl orthosilicate is completely hydrolyzed;

[0033] 3) Add 2 mL of accelerator to the solution obtained in step 2 at a dropping rate of 0.2 mL·min-1, stir for 25 minutes, and then seal the sol in an oven for gelation, the temperature of the oven is 40℃, and the gelation time is 9h ;

[0034] 4) The resultant in step 3 is composed of gel and liquid. Pour out the liquid, then add absolute ethanol until the gel is submerged, and seal it in an oven at 40°C for aging;

[0035] 5) Repeat step 4 5 times to obtain wet gel A after the replacement of absolute ethanol;

Example Embodiment

[0036] Example 2

[0037] 1) Weigh 7g of phase separator and add it to a strong acid solution with a concentration of 0.05mol·L-1, and stir until the phase separator is completely dissolved;

[0038] 2) Add 2 mL of the precursor silicon source to the solution obtained in step 1, and stir for 4 hours until the precursor silicon source is completely hydrolyzed;

[0039] 3) Add 2 mL of accelerator to the solution obtained in step 2 at a dropping rate of 0.2 mL·min-1, stir for 25 minutes, and then seal the sol in an oven for gelation, the temperature of the oven is 40℃, and the gelation time is 9h ;

[0040] 4) The resultant in step 3 is composed of gel and liquid. Pour out the liquid, then add absolute ethanol until the gel is submerged, and seal it in an oven at 40°C for aging;

[0041] 5) Repeat step 4 5 times to obtain wet gel B after the replacement of absolute ethanol;

Example Embodiment

[0042] Example 3

[0043] A preparation method of energy-saving and heat-insulating foamed rubber, which is calculated in parts by weight, and includes the following raw materials:

[0044] 150 parts of rubber compound, 15 parts of wet gel A, 5 parts of foaming agent, 0.1 part of foaming aid and 0.1 part of vulcanizing agent.

[0045] The preparation method of energy-saving thermal insulation foamed rubber is:

[0046] 1) Mix the rubber compound, wet gel, foaming agent, foaming aid and vulcanizing agent to obtain a premix after mixing in an internal mixer, and the mixing temperature is 60°C;

[0047] 7) Put the premix obtained in step 6 into an electrothermal constant temperature blast drying oven and freely foam at a temperature of 150°C for 3 minutes to obtain a pre-foamed glue;

[0048] 8) The pre-foamed rubber obtained in step 7 is made into a semi-finished product, and the single side of the semi-finished product is closely attached to the surface of the dense pallet, and the semi-f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap