Driving Mechanism and Working Method of Grass Silk Planting Machine

A driving mechanism and working method technology, applied in the field of grass silk planting, can solve problems such as damage to the lawn and unfavorable quality of the grassland, and achieve the effects of reducing damage, improving efficiency and convenience, and ingenious structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

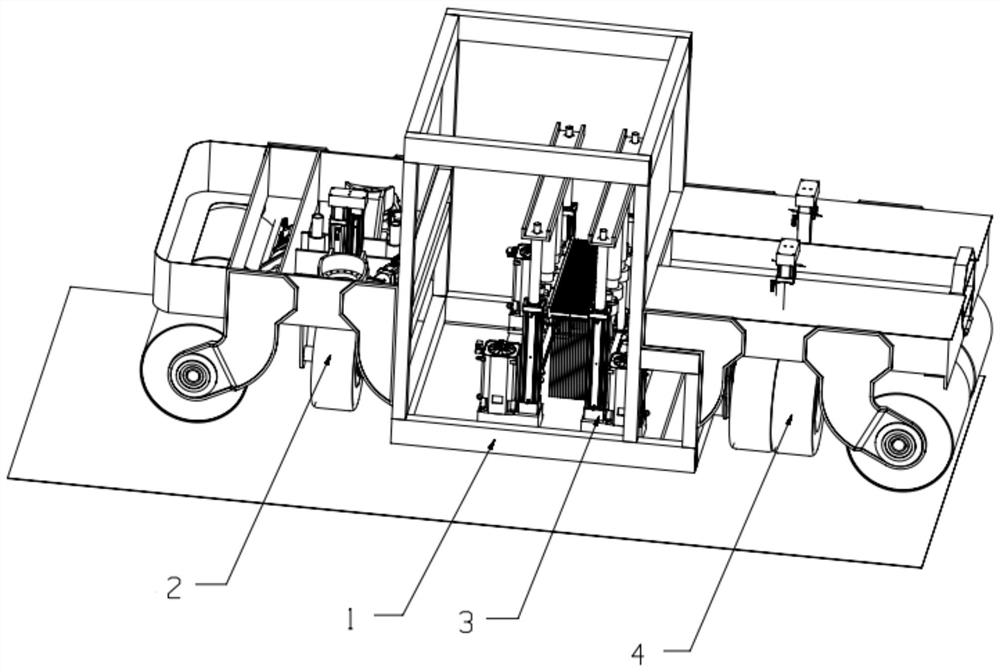

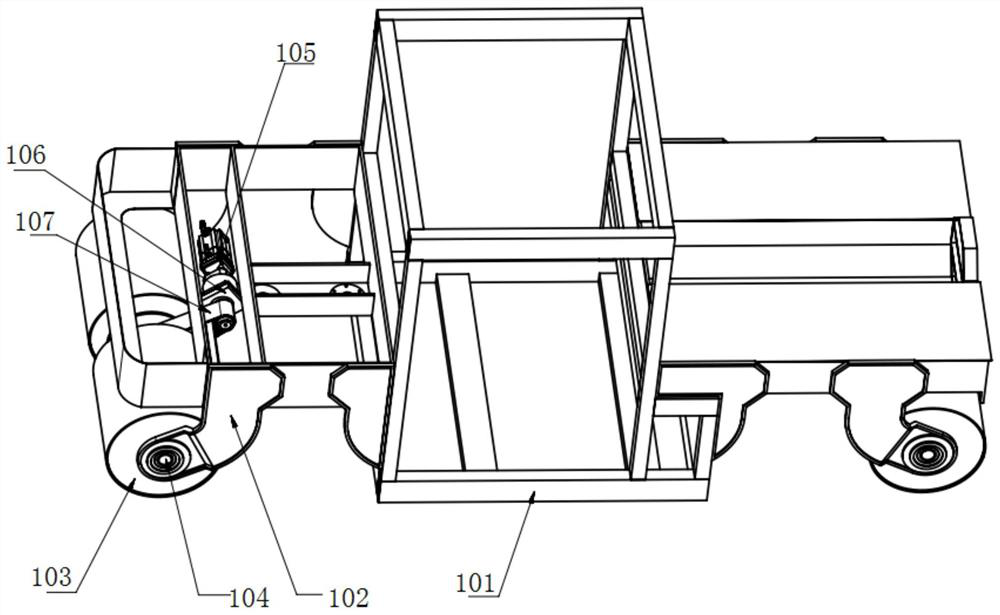

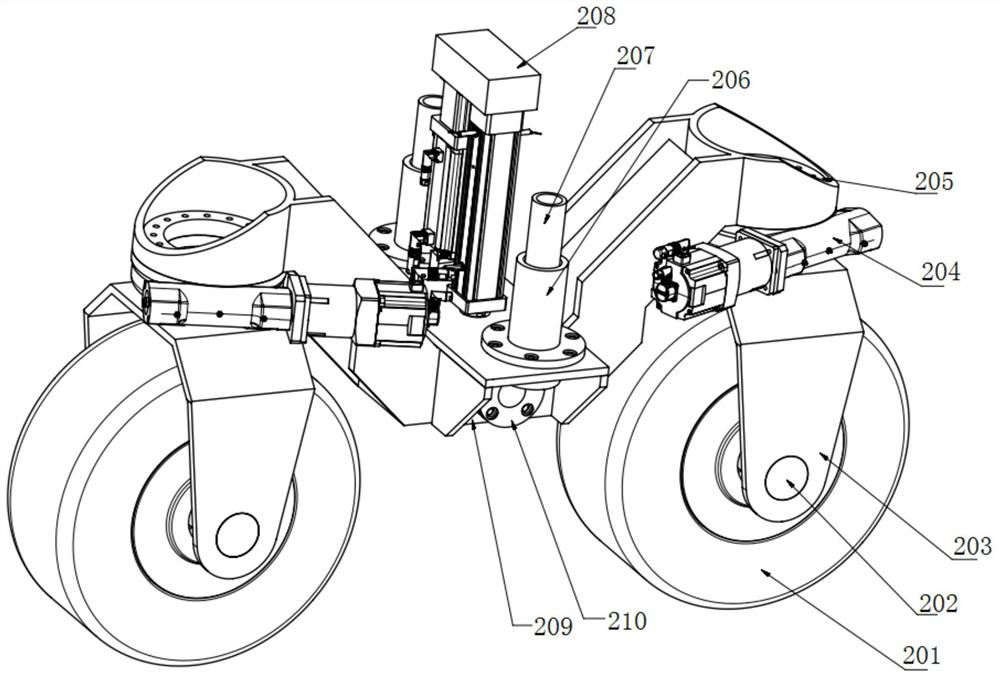

[0036] see figure 1 , a grassland silk planting machine driving mechanism, including a main frame system 1, a sub-frame system; the main frame system 1 and the sub-frame system each have an independent road wheel mechanism, and the walking of the respective road wheel mechanisms The directions are different; the main and auxiliary frame systems can move relative to each other in the vertical direction under the action of the jacking power mechanism.

[0037] In this embodiment, the main frame system 1 and the sub-frame system are vertically guided and positioned through guide columns, and the jacking power mechanism uses an electric cylinder. Specifically: the main frame system 1 is connected with the first sub-frame system 2 and the second sub-frame system 4 by electric cylinders and guide columns. Under normal working conditions, the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com