Defrosting method and device for supercooling refrigerant in refrigeration main pipeline by using defrosting medium

A main pipeline and refrigerant technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of less cooling capacity and underutilization of refrigerant cooling capacity, and achieve the effect of more cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

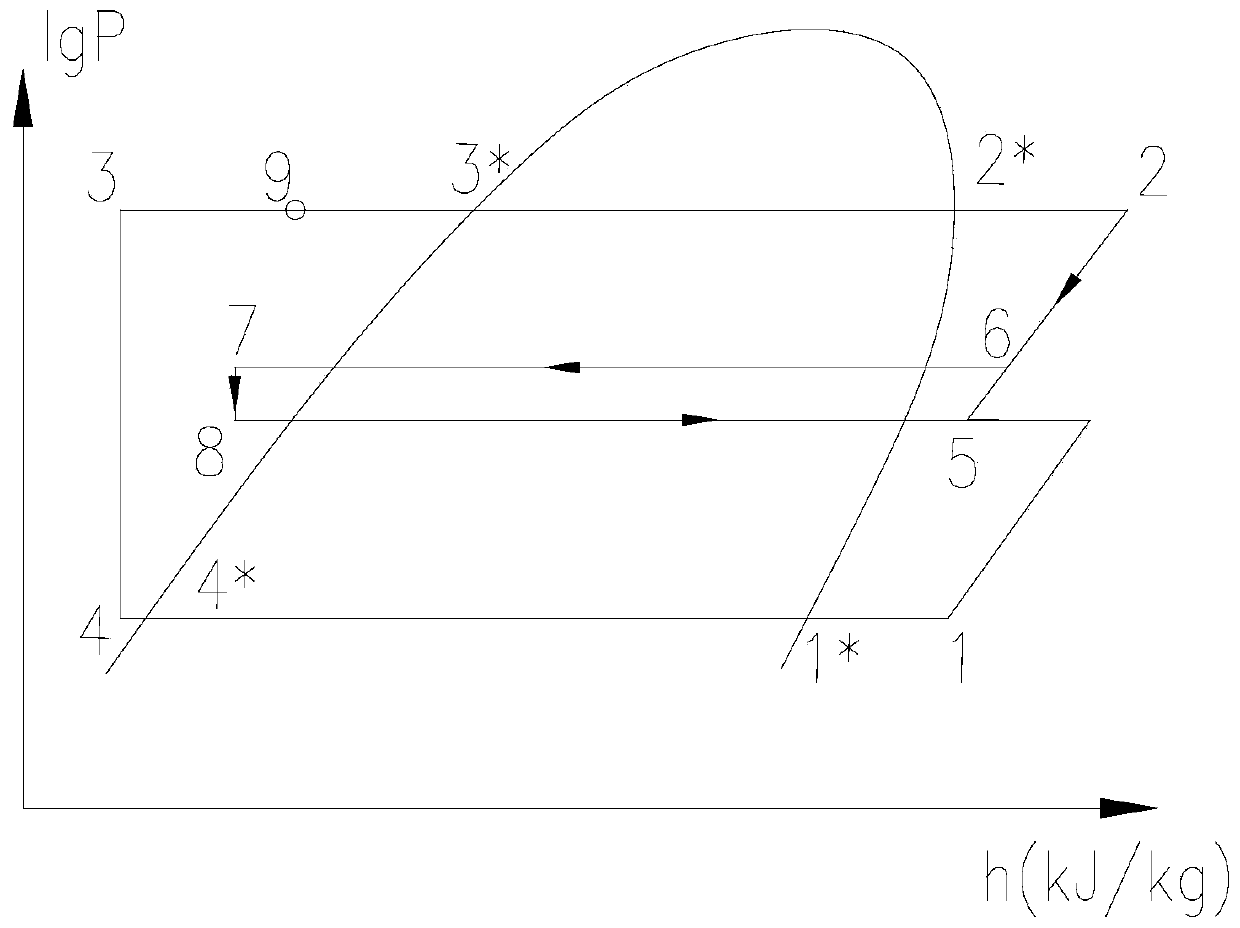

Method used

Image

Examples

Embodiment 1

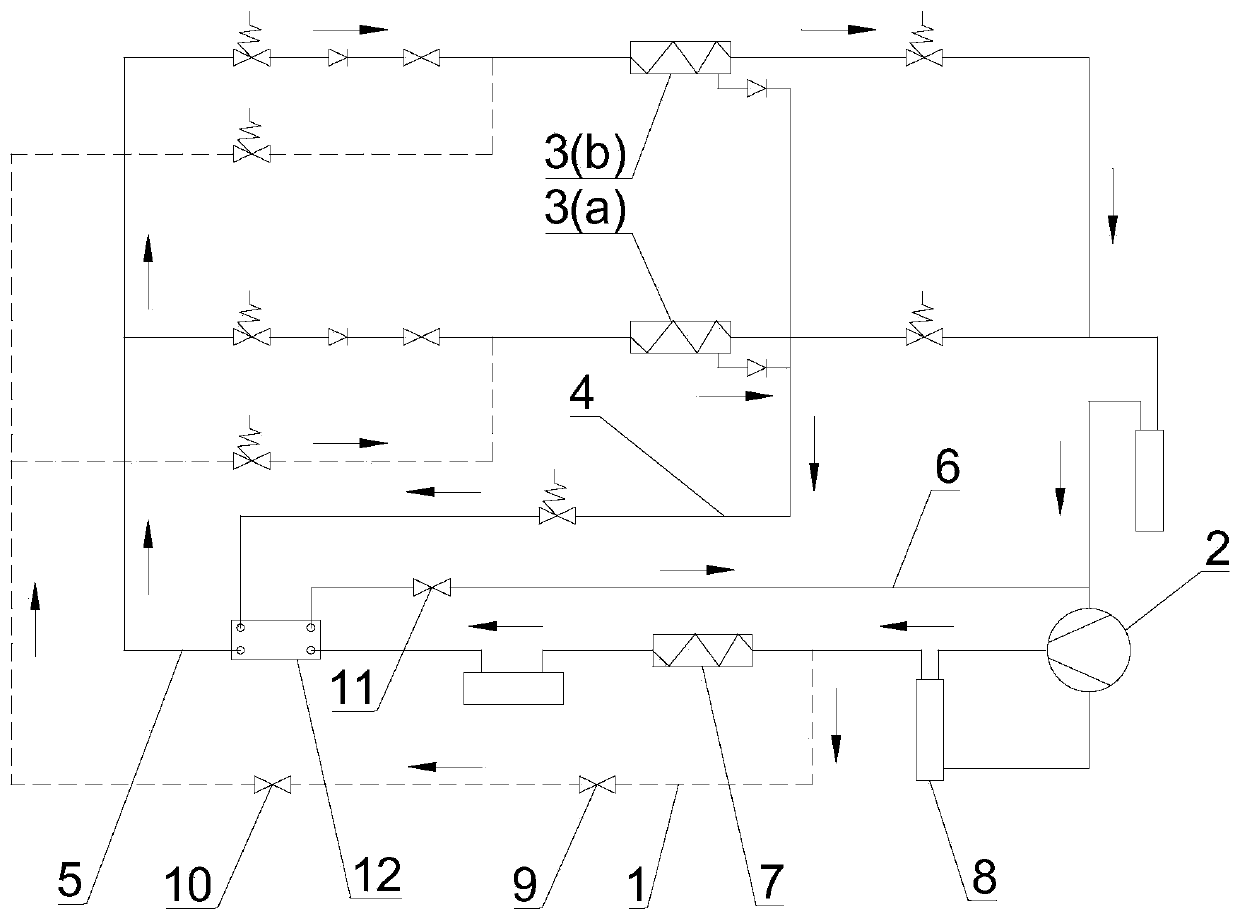

[0030] see figure 2 In this embodiment, the defrosting device that utilizes the defrosting medium to supercool the refrigerant in the main pipeline is integrated in the refrigeration system, and includes the evaporator 3 (a ) in the defrosting pipeline 1, the main pipeline cooler for supercooling the refrigerant in the refrigeration main pipeline 5, and the defrosting outlet pipeline 4 for transporting the defrosted refrigerant to the main pipeline cooler , the defrosting pipeline 1 is connected to the refrigeration main pipeline 5, the head end of the defrosting liquid outlet pipeline 4 is connected to the outlet of the evaporator 3 (a) to be defrosted, and the end is connected to the main pipeline cooler of the import.

[0031] see figure 2 , the first end of the defrosting pipeline 1 is connected between the compressor 2 and the condenser 7, and the end is connected to the inlet of the evaporator 3 (a) to be defrosted. In this way, the gas refrigerant with a high entha...

Embodiment 2

[0043] The difference from Embodiment 1 is that in this embodiment, the liquid refrigerant condensed by the condenser 7 is diverted to the evaporator 3 (a) to be defrosted through the defrosting pipeline 1, and the liquid refrigerant is used as the defrosting medium, exothermic to melt frost on the evaporator.

[0044] Of course, the defrosting medium can also be a vapor-liquid mixture refrigerant, and the vapor-liquid mixture refrigerant can be obtained by mixing gas refrigerant and liquid refrigerant; in addition, the vapor-liquid mixture refrigerant can also be obtained by The liquid refrigerant is throttled and then absorbed heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com