Automatic sampling device for hydrogeological survey

An automatic sampling and hydrogeological technology, applied in the field of geological exploration, can solve the problems of low sampling efficiency, inability to accurately locate the sampling depth, poor sealing performance, etc., to improve sampling accuracy and stability, realize continuous automatic sampling, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

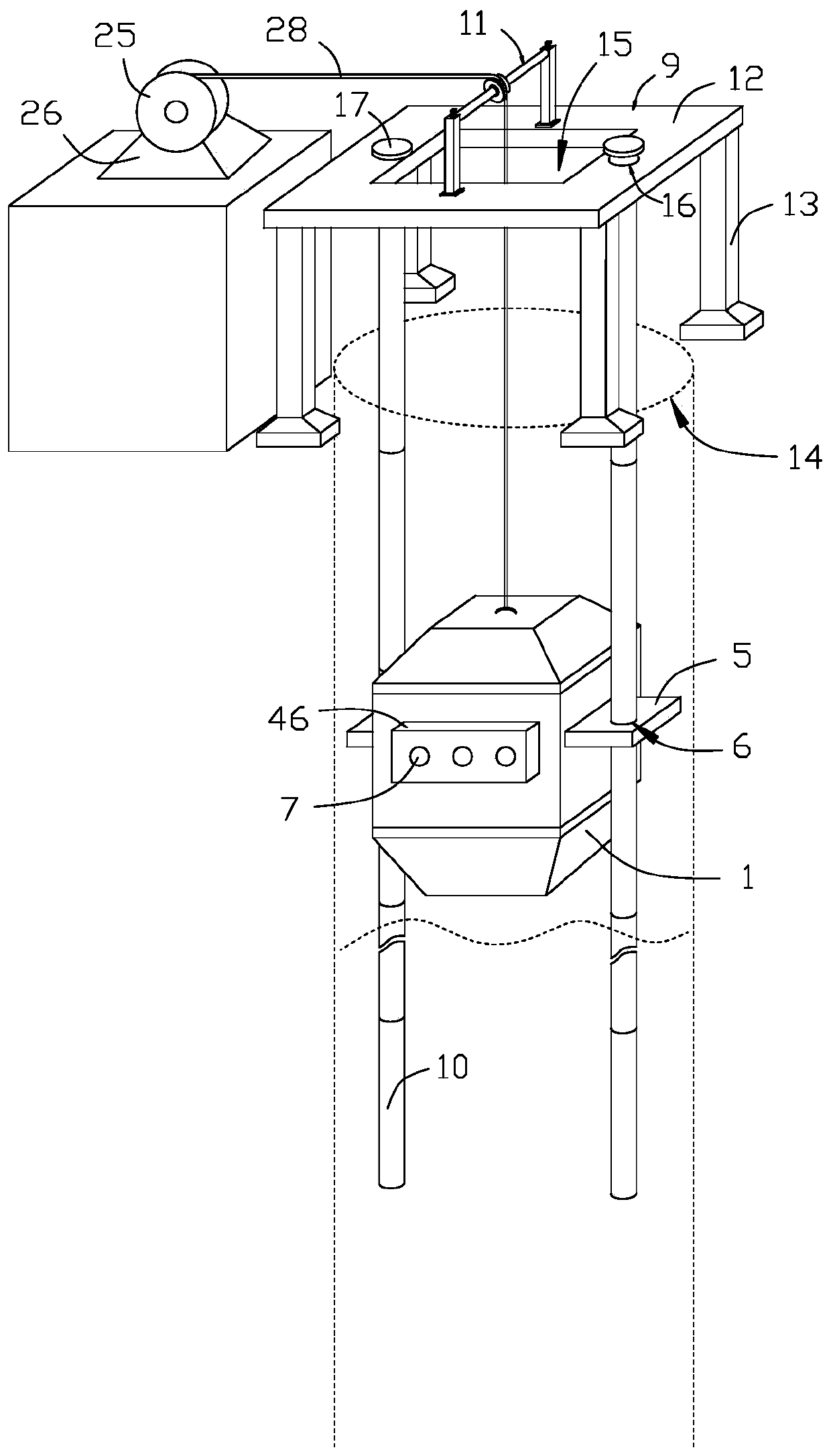

[0092] Such as figure 1 As shown, the present invention relates to an automatic sampling device for hydrogeological survey, which includes a sampling box 1, a sampling box guiding mechanism, a sampling box lifting mechanism, a sampling box positioning mechanism, a sampling mechanism and a host computer.

[0093] The function of the sampling box 1 is to realize the installation of the sampling mechanism and the like.

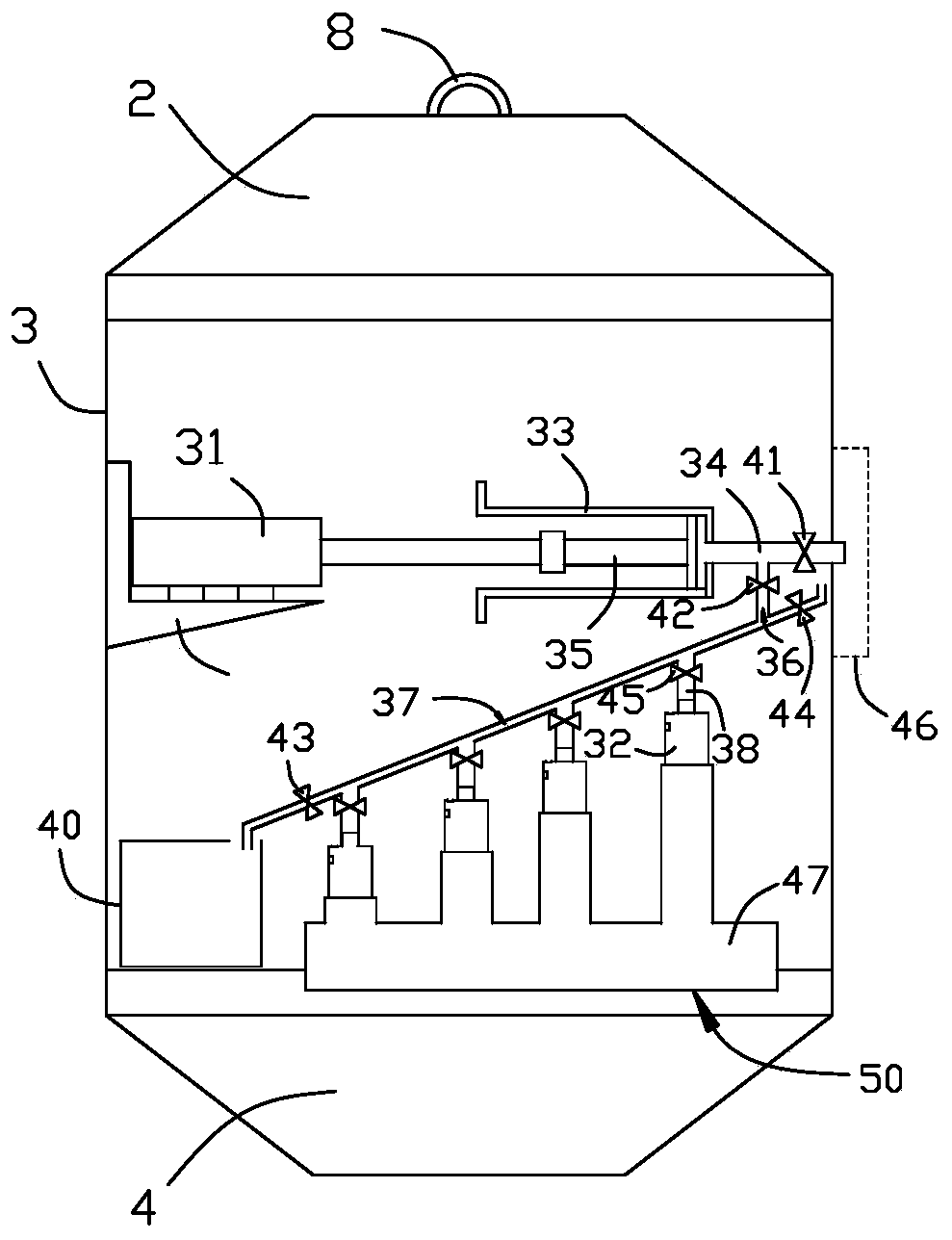

[0094] Such as figure 2 As shown, the sampling box 1 includes a box top cover 2 , a box body 3 and a box bottom cover 4 .

[0095] The box body 3 is square, such as figure 1 shown. The box body 3 has four side walls, and the direction toward the outside of the paper is defined as the front. Then, a guide plate, such as a guide plate 5 , is provided on the left and right opposite side walls of the box body 1 .

[0096] Taking one of the guide plates 5 as an example, each guide plate 5 is provided with a guide hole 6 to facilitate the realization of the guide ...

Embodiment 2

[0176] Present embodiment 2 has described a kind of automatic sampling method for hydrogeological survey, and this automatic sampling method is based on the automatic sampling device for hydrogeological survey mentioned in above-mentioned embodiment 1, as Figure 9 As shown, it includes the following steps:

[0177] I. Assemble each mechanism of the automatic sampling device for hydrogeological investigation in turn, and complete the assembly of the device;

[0178] II. The upper computer controls the rotation of the deceleration motor 27, and the cable reel 25 automatically unwinds the cable. At this time, under the action of the guide rod 10, the sampling box steadily descends. During the descent, the sampling box positioning mechanism monitors the sampling box 1 in real time. drop height.

[0179] III. When the sampling box 1 drops to the predetermined depth position, the host computer controls the deceleration motor 27 to stop, and at this time, the sampling box 1 stops p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com