A loading fixture device for cross-shaped specimen biaxial equal load and non-equal load fatigue test

A technology of fatigue test and fixture device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

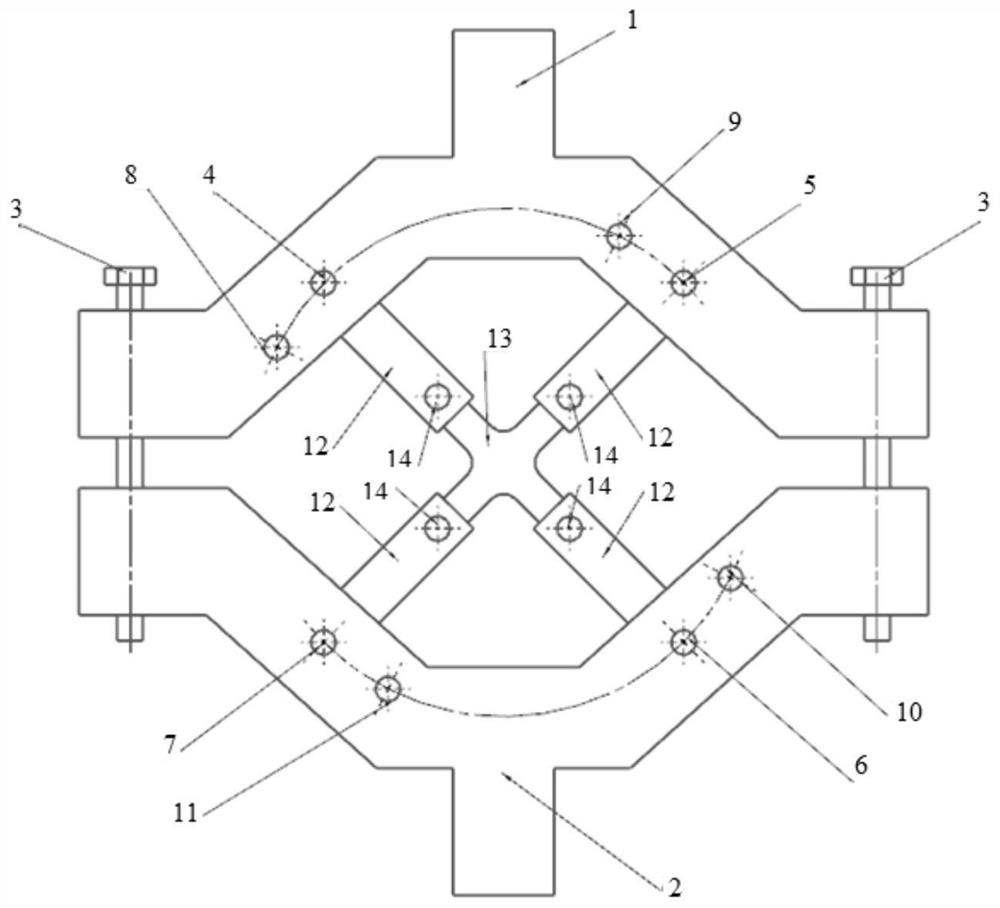

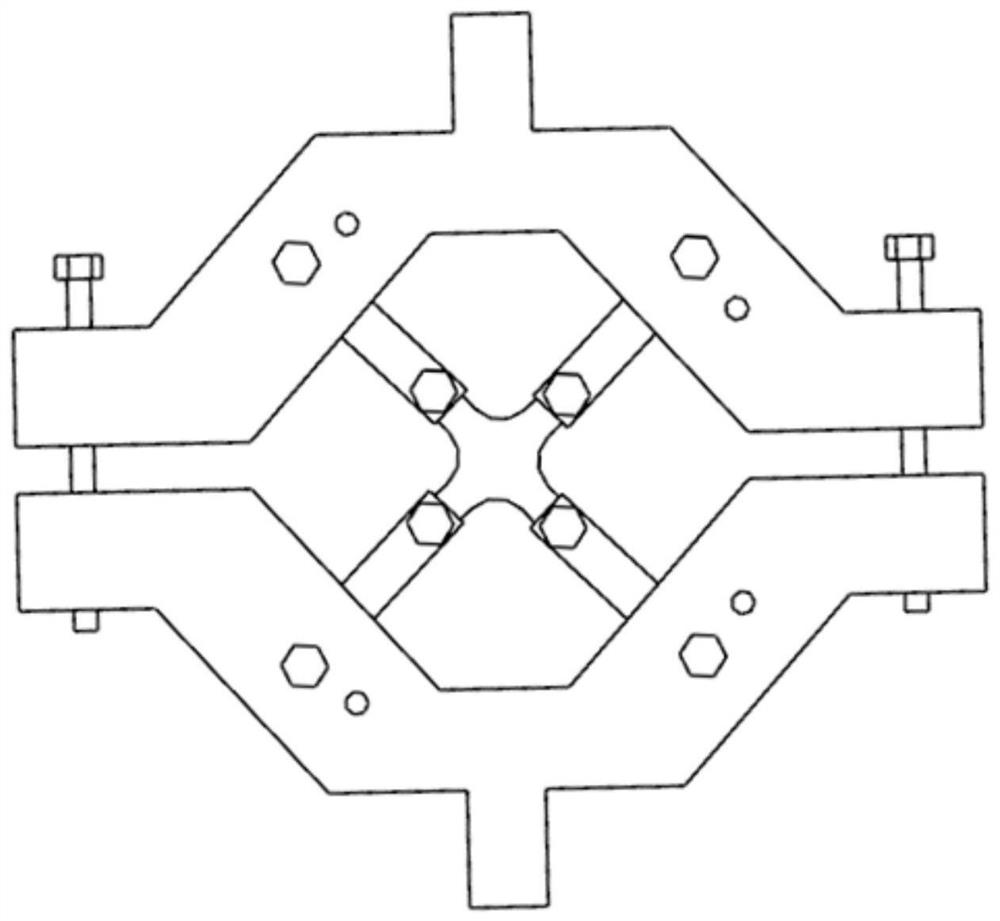

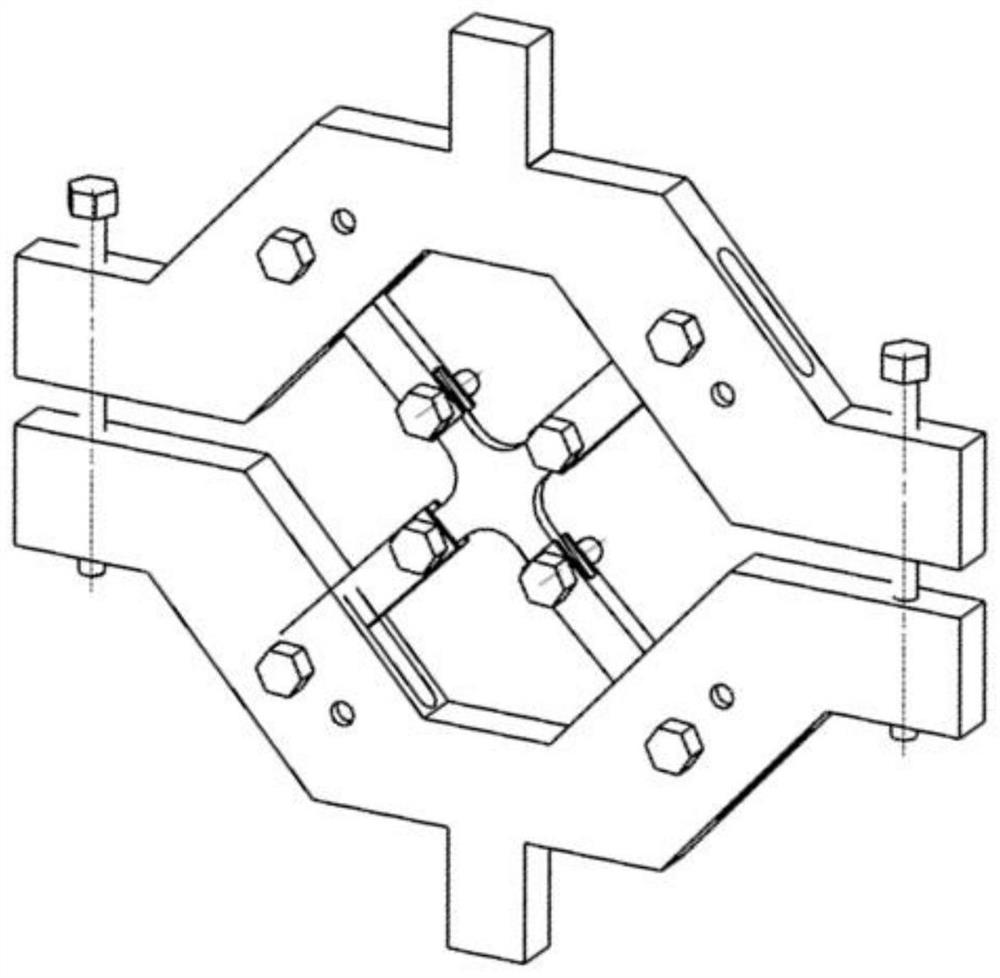

[0026] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, the present invention proposes a loading fixture device for biaxial equal-load and non-equal-load fatigue tests of a cross-shaped test piece, including a cross-shaped test piece 13, an upper splint 1 and a lower splint 2 correspondingly distributed up and down, and a cross-shaped test piece. The piece 13 is set in the accommodation cavity formed between the upper splint 1 and the lower splint 2, and four symmetrically distributed tie rods 12 are arranged between the upper splint 1 and the lower splint 2, and the cross-shaped test piece 13 is connected to the upper splint respectively through the tie rods 12. 1. The lower splint 2 is mated and connected. The two ends of the upper splint 1 and the lower splint 2 are provided with positioning guide rods 3. The upper splint 1 is tightly connected with the lower splint 2 through the positioning guide rod 3 to fix the upper splint 1 and the lower splint. 2. It can...

Embodiment 2

[0030] Embodiment 2: The line connecting the centers of the fifth round hole 8 and the seventh round hole 10 is 60 degrees to the center line of the upper splint 1 and the lower splint 2, and the rest are the same as in the first embodiment.

Embodiment 3

[0031] Embodiment 3: The upper splint 1 and the lower splint 2 are provided with a rectangular tie rod installation through groove corresponding to the tie rod 12, and the tie rod 12 is installed in the tie rod installation through groove, and the tie rod 12 is connected to the upper splint 1 and the lower splint 2 by bolts 14. Tightly connected, the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com