A test device for buried pipelines across seismic faults

A technology for testing devices and buried pipelines, which is applied in measuring devices, mechanical devices, and testing of machine/structural components. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

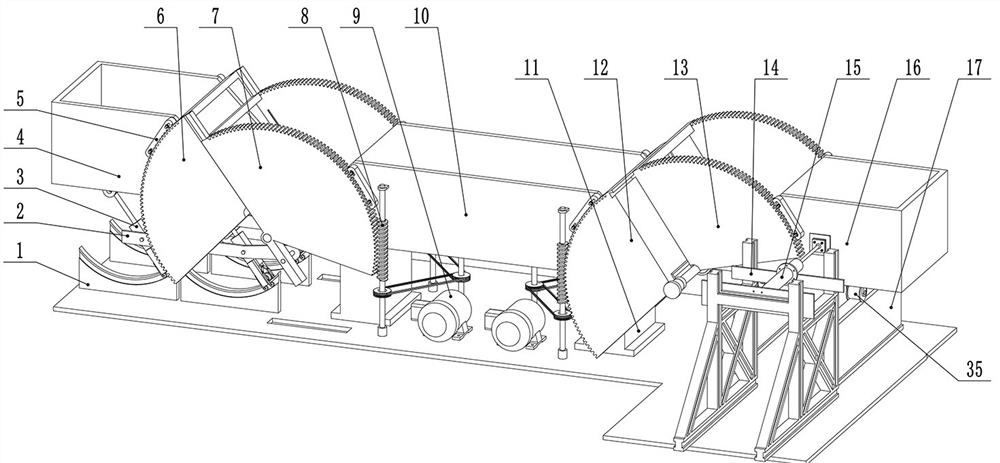

[0026] Example 1: Positive and reverse fault test process

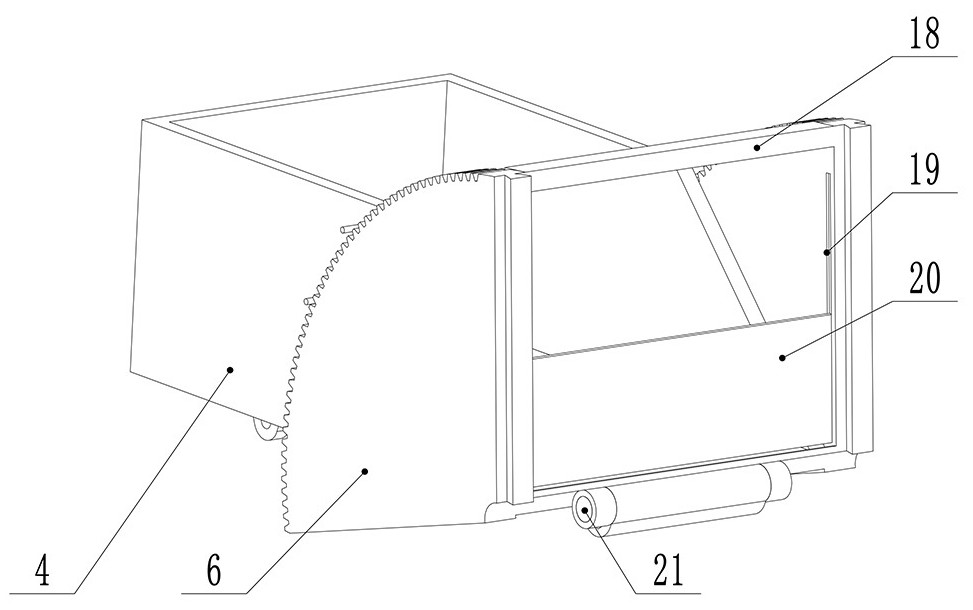

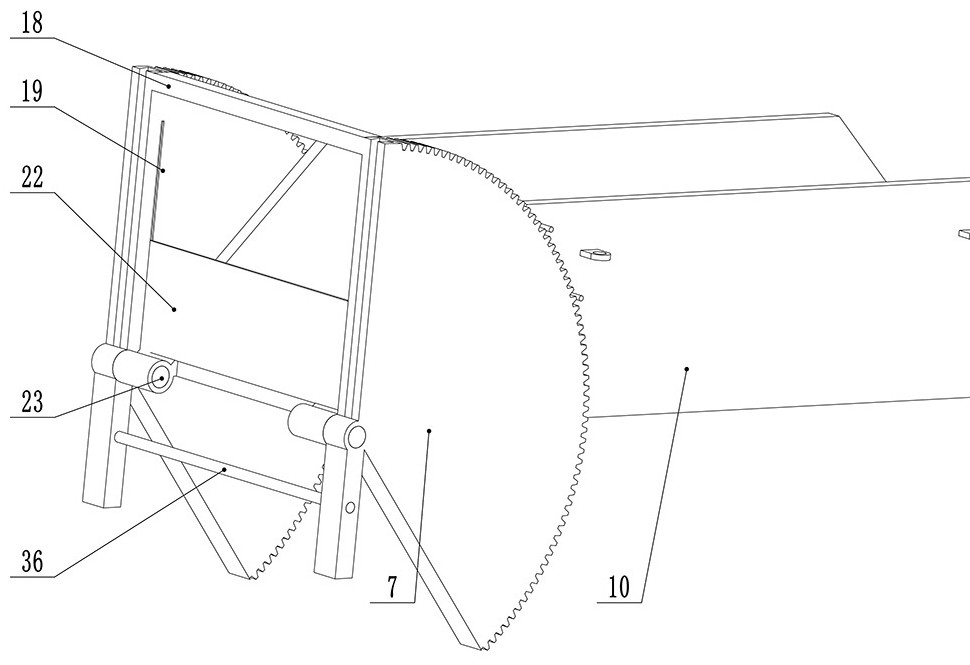

[0027] like Figure 1 to Figure 4 As shown, the fixed earth box 10 is anchored to the fixed support 11 . The left side of the fixed earth box 10 is installed with an inclination adjustment worm gear left 2 7, and the vertically movable earth box 4 is installed with an inclination adjustment worm wheel left 1 6. The left one 6 and the left two 7 of the inclination adjustment worm gear each contain two pieces, which are respectively arranged on both sides of the vertically moving soil box 4 and the fixed soil box 10. . A dovetail groove is radially processed between the left one 6 and the second left 7 of the inclination angle adjusting worm gear, and the two worm gears can slide radially after being assembled. Use pin one 21 to pass through the vertical moving earth box 4 and the left one 6 of the inclination adjustment worm gear, and the second pin 23 to pass through the fixed earth box 10 and the left two 7 inclin...

Embodiment 2

[0032] Example 2: Strike-slip (translational) fault test process

[0033] like figure 1 As shown, the bottom of the horizontally moving earth box 16 is equipped with a second limiting roller 35 , and the second limiting roller 35 drives the horizontally moving soil box 16 to move in translation along the limiting rail 17 . like Figure 7 , Figure 8 As shown, the right side of the fixed earth box 10 is installed with the right one 12 and the right three 26 of the inclination adjustment worm gear, which are installed on the outside and the inside of the fixed earth box 10 respectively, and are connected by the second tie rod 27, and the third earth retaining plate 25 is welded to the right one of the inclination adjustment worm gear. 12 and the second tie rod 27; the outside and the inside of the horizontally moving earth box 16 are respectively installed with the right second 13 and the right fourth 28 of the inclination adjustment worm gear, which are connected by the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com