Air-cooled mainframe chassis with internal environment temperature adjustment function and method

A temperature-adjusting, air-cooled technology, applied in the field of air-cooled mainframe chassis, can solve problems such as inability to dissipate heat, be easily attached by dust, and slow heat dissipation, and achieve fast heat dissipation, good dust-proof effect, and prevent dust from being carried out Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

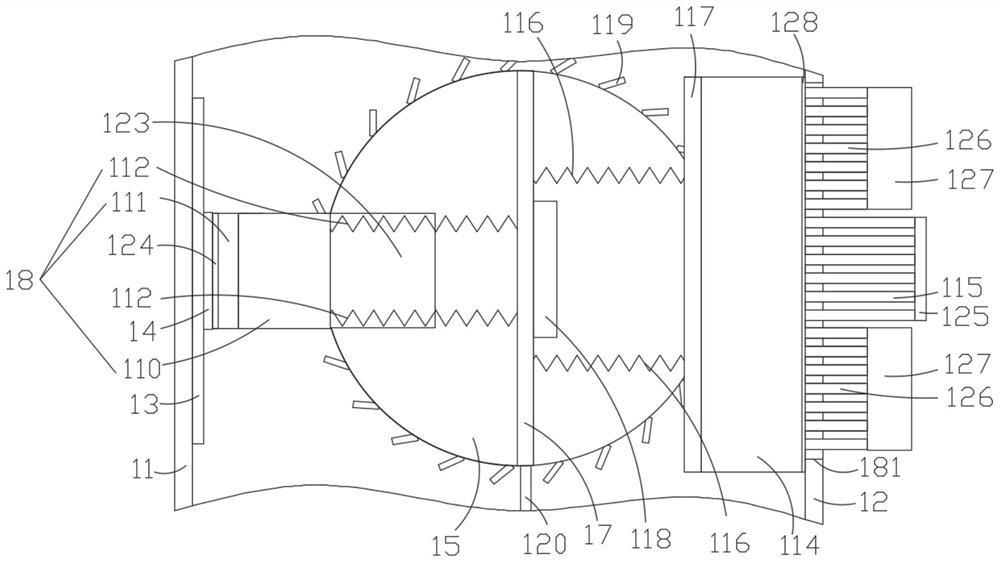

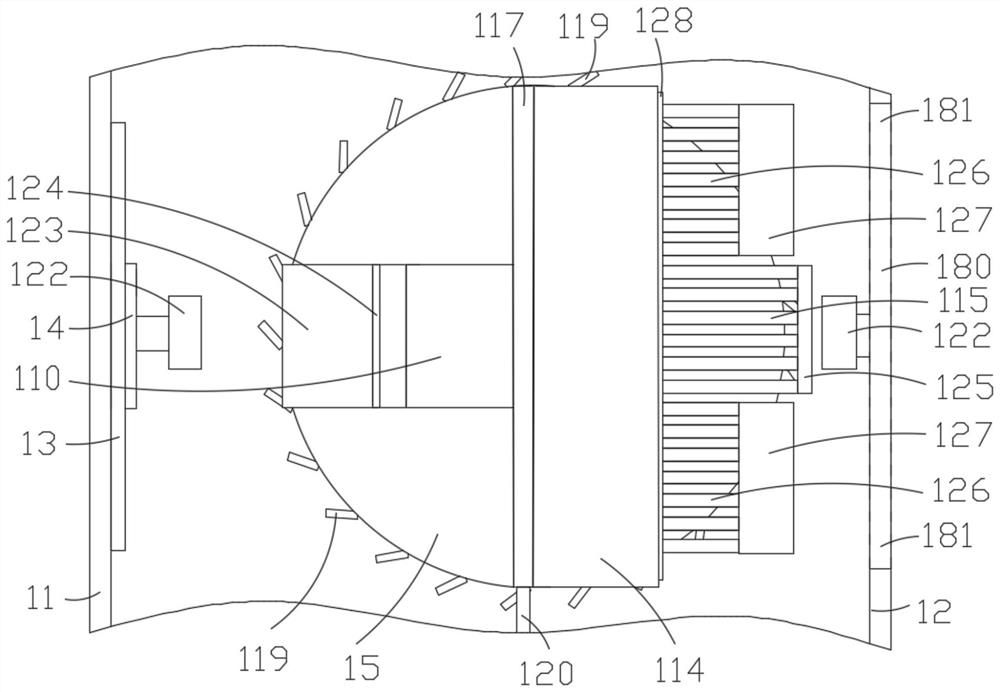

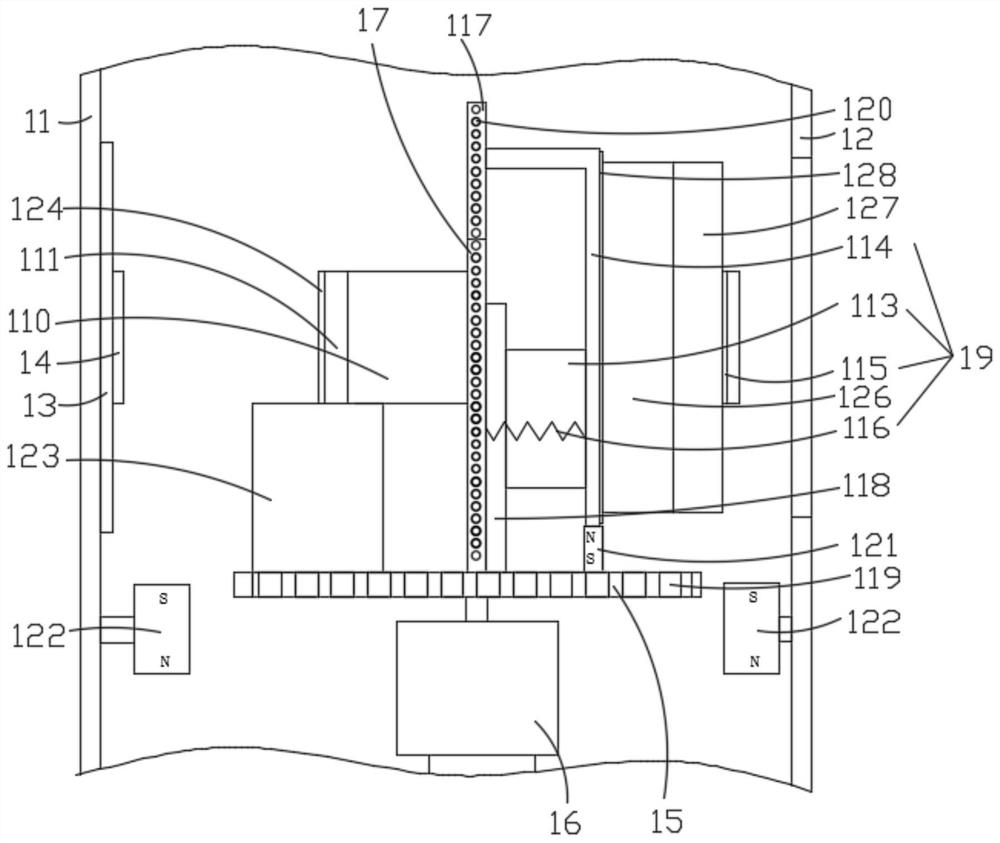

[0029] The embodiment of the present invention provides an air-cooled mainframe chassis with the function of adjusting the temperature of the internal environment, such as Figure 1-Figure 3 As shown, comprise main engine chassis; Main engine chassis comprises left side plate 11 and right side plate 12; On the inner wall of left side plate 11, be fixed with longitudinal main control panel 13; Main control panel 13 is fixed with CPU14; In the main engine chassis A horizontal turntable 15, a rotating assembly 16 that drives the turntable 15 to rotate on a horizontal plane, a lower fan plate 17 fixed on the middle of the upper surface of the turntable 15, and first heat dissipation components 18 distributed on both sides of the lower fan plate 17 are provided. and the second cooling assembly 19;

[0030] The first heat dissipation assembly 18 includes a first iron block 110, a thermal pin group 111 fixed to the left side surface of the first iron block 110 and adapted to the CPU ...

Embodiment 2

[0050] An embodiment of the present invention provides a method for using an air-cooled mainframe chassis. Based on the air-cooled mainframe chassis with an internal environment temperature adjustment function provided in Embodiment 1, the method includes the following steps:

[0051] Step S101: Enable air cooling

[0052] The electromagnet is energized, the first iron block and the second iron block are adsorbed, the heat conduction needle group and the first heat dissipation fin group return to the turntable, and the upper fan board and the lower fan board are brought together;

[0053] The rotating assembly drives the turntable to rotate back and forth, and the lower fan plate and the upper fan plate cooperate to fan the main control board and the electronic components installed on the main control board;

[0054] Step S102: Start the heat conduction needle group to dissipate heat

[0055] After air cooling for a certain period of time, the rotating assembly drives the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com