High-efficient radial heat pipe for heat transfer and finned pipe thereof

A finned tube and heat pipe technology, which is applied in the field of high-efficiency radial heat transfer heat pipes and their finned tubes, can solve the problem of not finding three-layer casing heat pipes, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

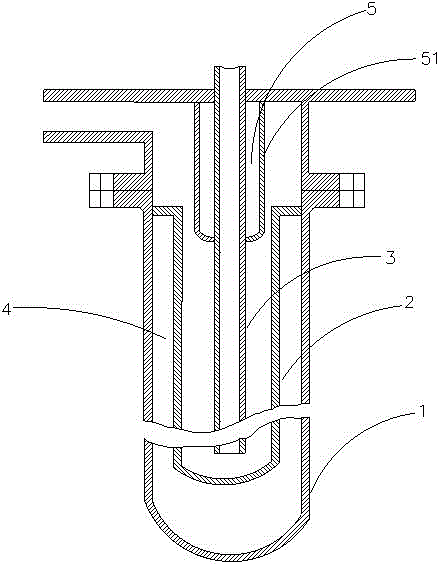

[0029] Such as figure 1 As shown, this embodiment provides a heat pipe with high efficient radial heat transfer, including a first layer of inner tubes 2, a second layer of inner tubes 3 and an outer tube 1 of different diameters, the first layer of inner tubes 2 and the second layer of inner tubes The tube 3 forms a double-layer inner tube, the first layer inner tube 2 is covered with the second layer inner tube 3; the outer tube 1 is covered with a double-layer inner tube; the first layer inner tube 2 communicates with the second layer inner tube 3; The layer inner tube 2 and the outer tube 1 are of a closed structure and form an annular channel heat pipe 4, the working medium of the first layer inner tube 2 can exchange heat with the working medium of the annular channel heat pipe 4; the annular channel heat pipe 4 exchanges heat with the outside; The working medium of the double-layer inner tube circulates in and out at one end of the heat pipe with high-efficiency radial ...

Embodiment 2

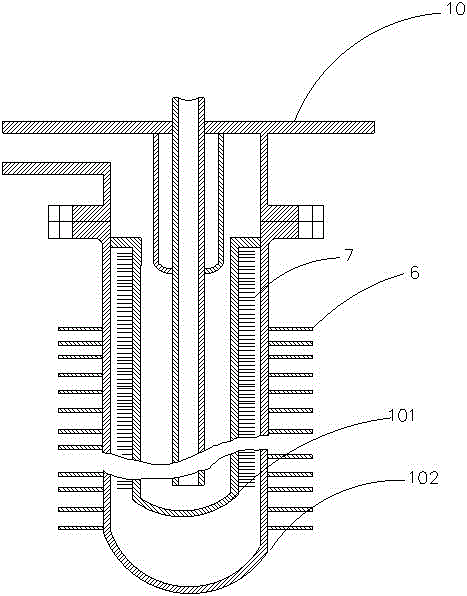

[0036] Such as figure 2 As shown, this embodiment provides a finned tube, including a heat pipe 10 with high-efficiency radial heat transfer, an inner tube fin 7 is arranged in the heat pipe of the annular channel, and the inner tube fin 7 is arranged on the inner tube 101 of the first layer. The inner tube fins 7 are not in contact with the inner wall of the outer tube 102, and the distance between the inner tube fins 7 and the inner wall of the outer tube 102 is 0.5mm. The sheet 7 is provided with a slit to form a gas channel for the free flow of gas; the outer wall of the outer tube 102 is provided with an outer tube fin 6 .

[0037] In this embodiment, the inner tube 101 of the first layer of finned tubes is provided with inner tube fins 7, which not only helps to accelerate the condensation rate of water vapor, but also helps to balance the heat exchange capacity on both sides of the gas and liquid, because the gaseous fluid ratio The heat transfer coefficient of liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com