Ring winding reluctance motor, system and control method thereof

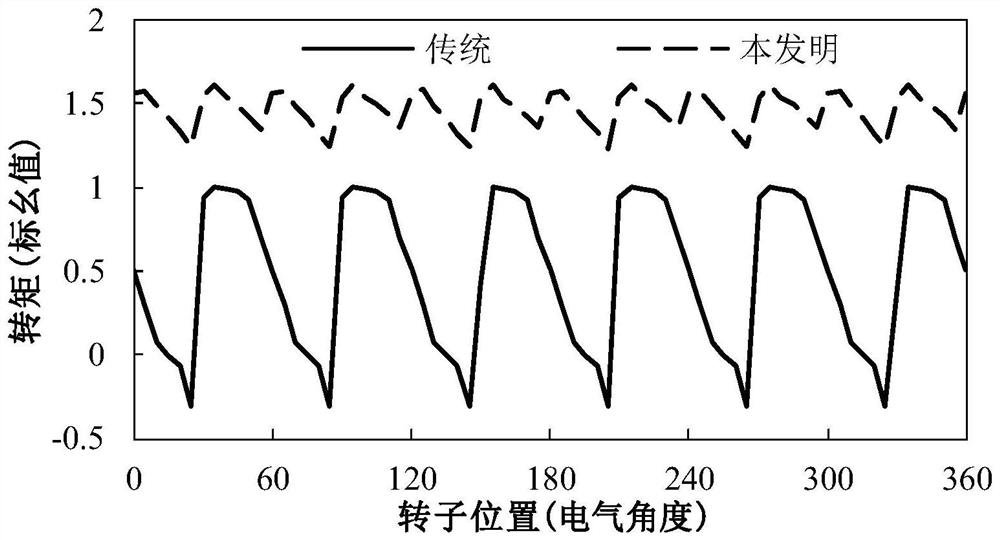

A technology of toroidal winding and reluctance motors, which is applied in the direction of windings, electromechanical devices, electrical components, etc. It can solve the problem of large fluctuations in tangential torque and radial magnetic pull, weakening the torque capacity of the motor, reducing the torque density of the motor, etc. problems, to achieve the effect of torque ripple vibration noise, improve versatility and scale effect, and high motor slot full rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

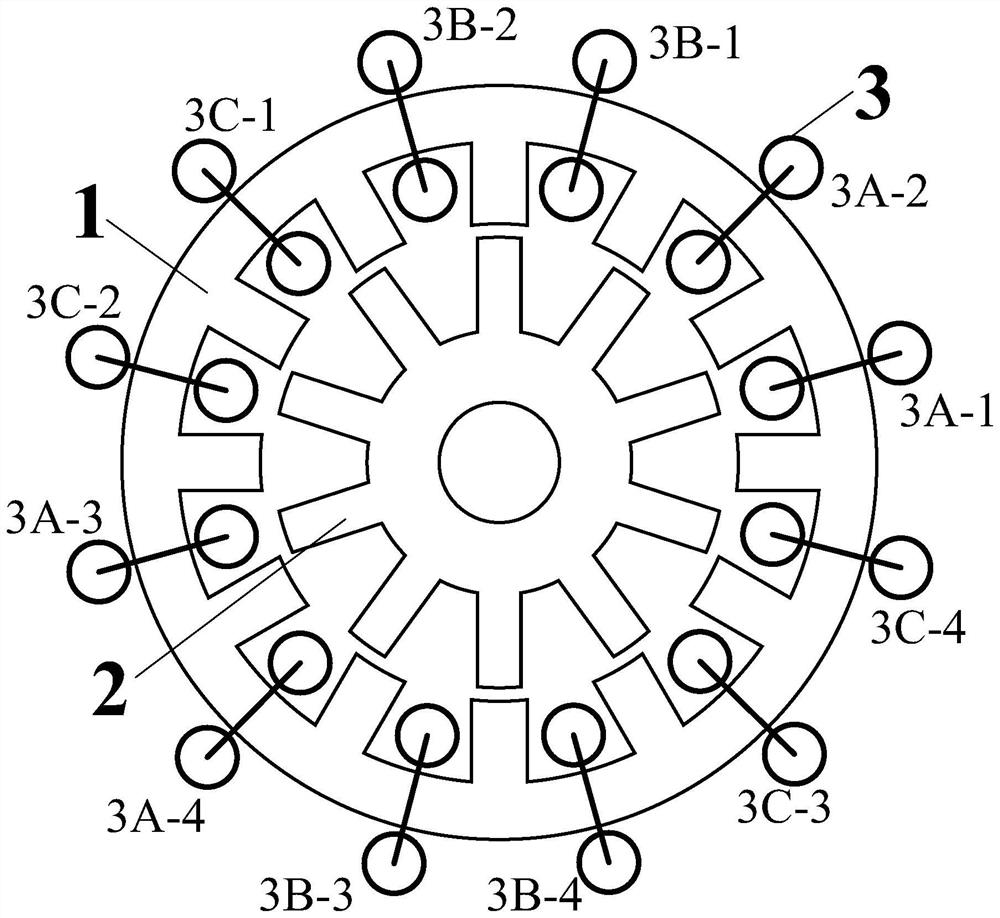

[0043] figure 1 It is a schematic cross-sectional structure schematic diagram of a ring-winding reluctance motor in an embodiment of the present invention.

[0044] Such as figure 1As shown, in this embodiment, the ring-winding reluctance motor is a radial magnetic field rotating motor with an inner rotor structure. The stator has twelve slots, the rotor has ten poles, and the armature winding has three phases and contains twelve armature winding coils.

[0045] Specifically, it includes a stator core 1, a rotor core 2, and an armature winding 3. Wherein, the rotor core 2 is located inside the stator core 1 to form an inner rotor structure (of course, in some other embodiments, it can also be made into an outer rotor structure, that is, the rotor core 2 is located outside the stator core 1). Both the stator core 1 and the rotor core 2 can be made by laminating silicon steel punching sheets.

[0046] further reference figure 1 It can be seen that the armature winding 3 inc...

Embodiment 2

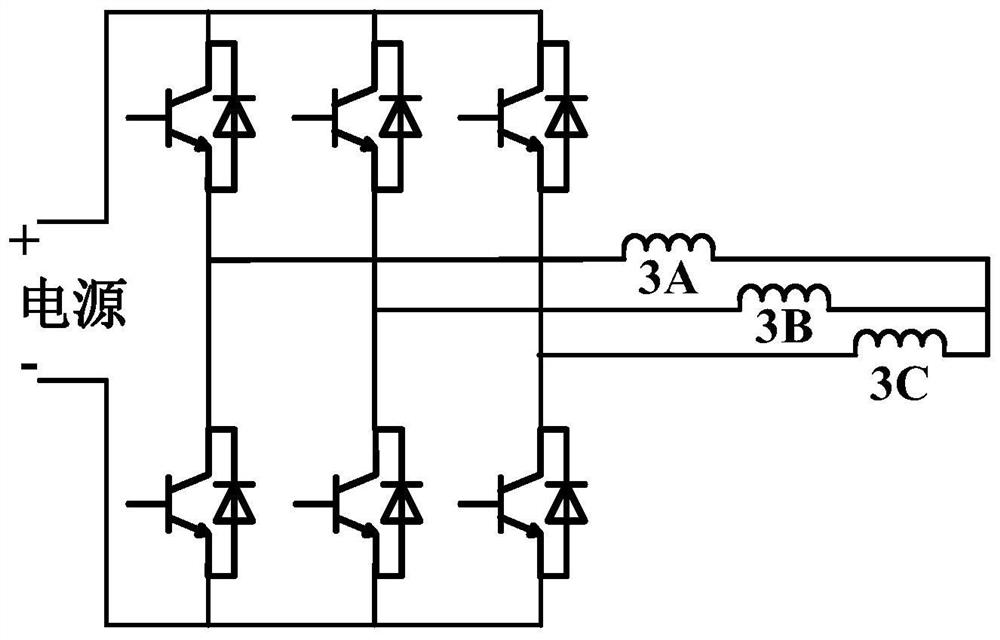

[0052] The structure of the toroidal winding reluctance motor system in embodiment 2 is basically the same as that of the toroidal winding reluctance motor system in embodiment 1, the difference being that the number of stator slots of the toroidal winding reluctance motor in embodiment 2 is six 1. The number of rotor poles is five, correspondingly, the armature winding 3 of the motor includes six armature winding coils, forming a symmetrical three-phase winding. It should be pointed out that, similar to Embodiment 1, in Embodiment 2, the armature winding 3 is electrically connected to the power converter based on the three-phase full-bridge circuit topology, and then the three-phase symmetrical sinusoidal current is loaded to realize the stable operation of the motor .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com