Battery cooling system of new-energy vehicle

A new energy vehicle and heat dissipation system technology, applied in the field of new energy vehicle battery heat dissipation system, can solve the problems of poor heat dissipation effect of new energy vehicle batteries, achieve various heat dissipation methods, prevent accumulation, and improve heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

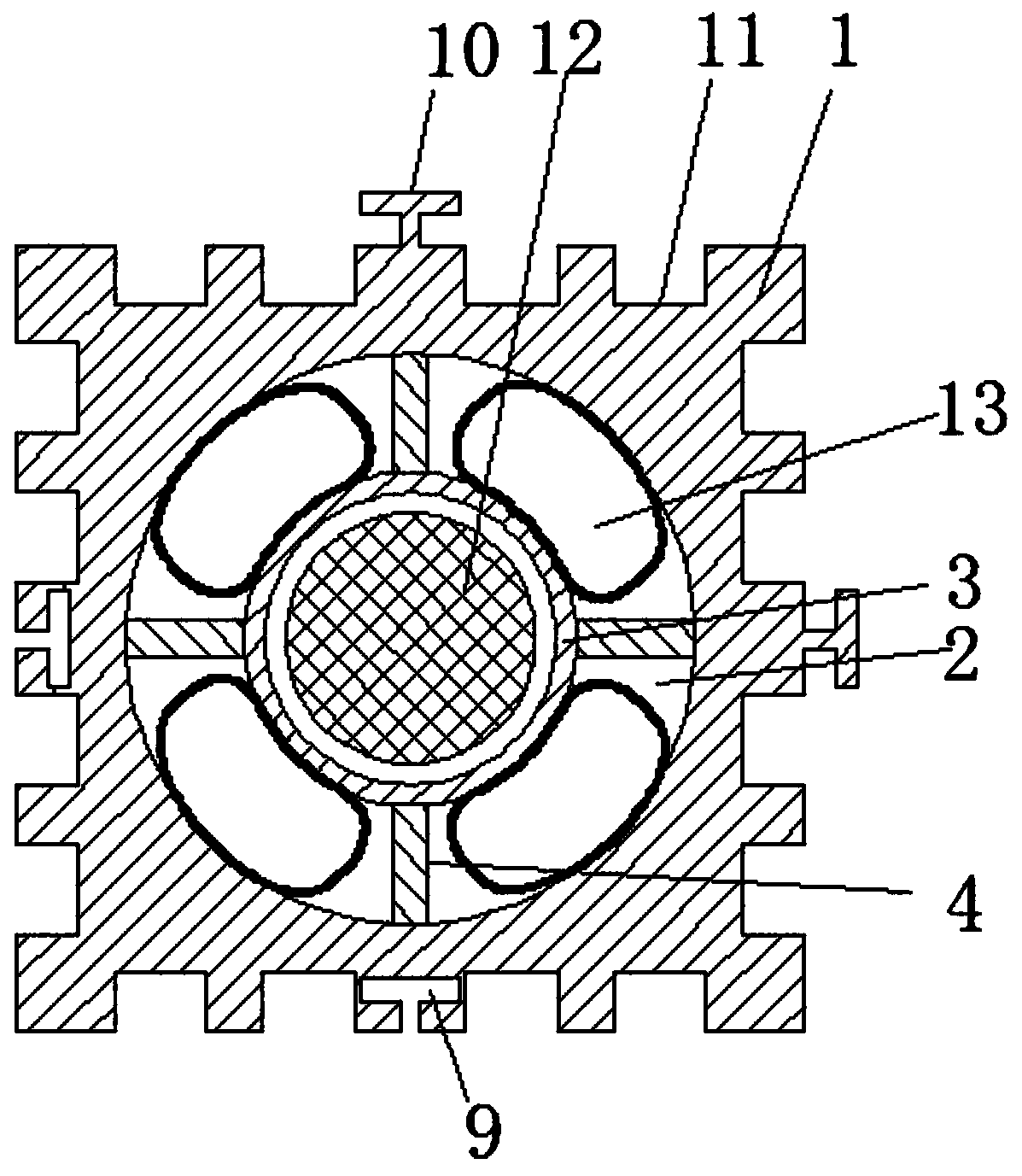

[0027] Such as figure 1 , figure 2 and Figure 6 As shown, a new energy vehicle battery heat dissipation system includes a battery packaging structure and a cooling system. The battery packaging structure includes a body 1, and the body 1 is used as a housing of the packaging structure. The ends respectively pass through the opposite ends of the body 1, and the cavity 2 is provided with a battery carrying device 3 for placing the battery. The battery carrying device 3 is made of a heat-conducting material. The ventilation channel is provided with a fixing part 4, and the battery carrying device 3 is connected to the inner wall of the cavity 2 through the fixing part 4; the ventilation channel is provided with a water storage bag 13 made of elastic heat-conducting material, and the water storage bag 13 is provided with an inlet The water port and the water outlet, and the water storage bag 13 are fixedly connected on the inner wall of the cavity 2 .

[0028] In this embodim...

Embodiment 2

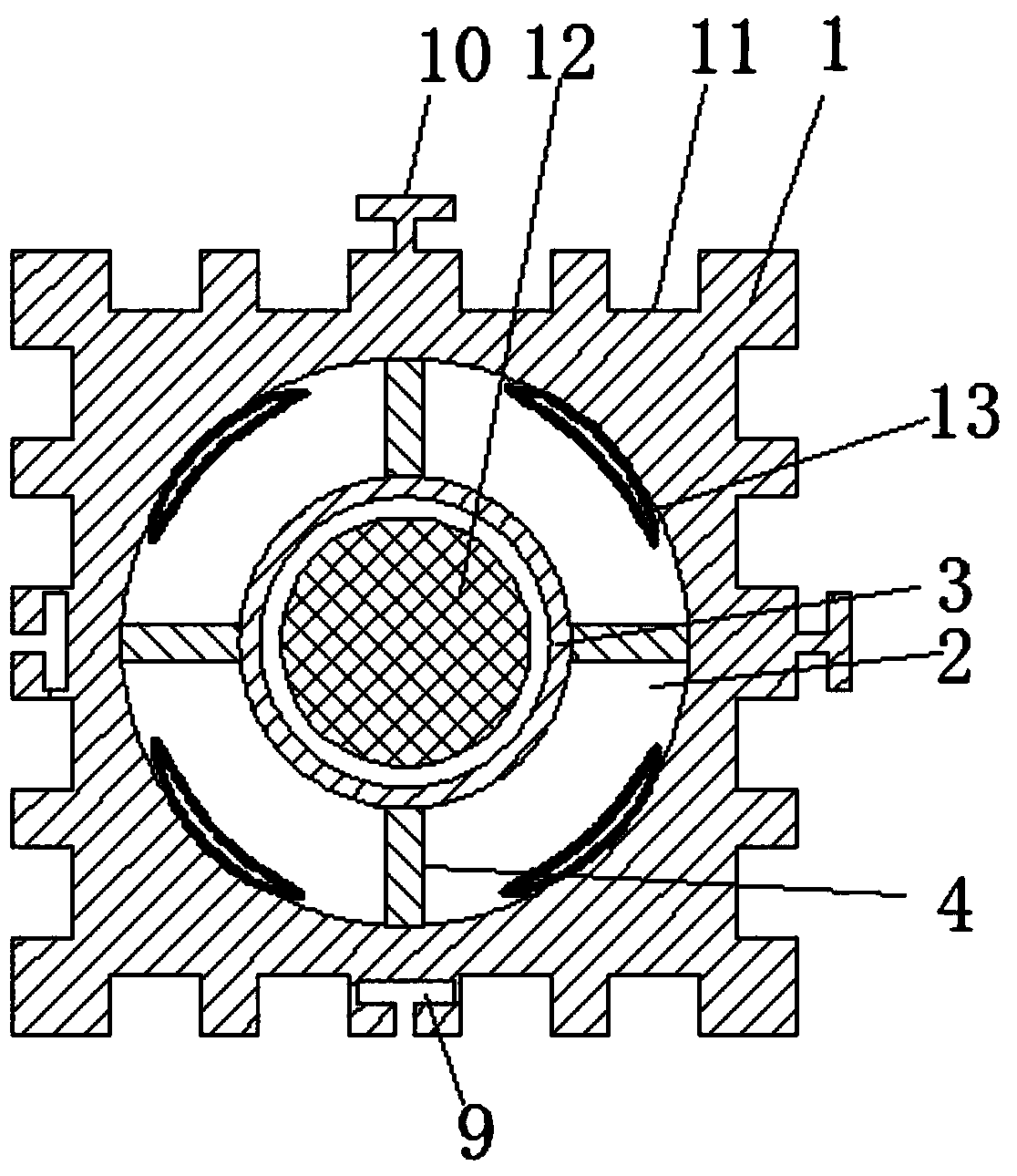

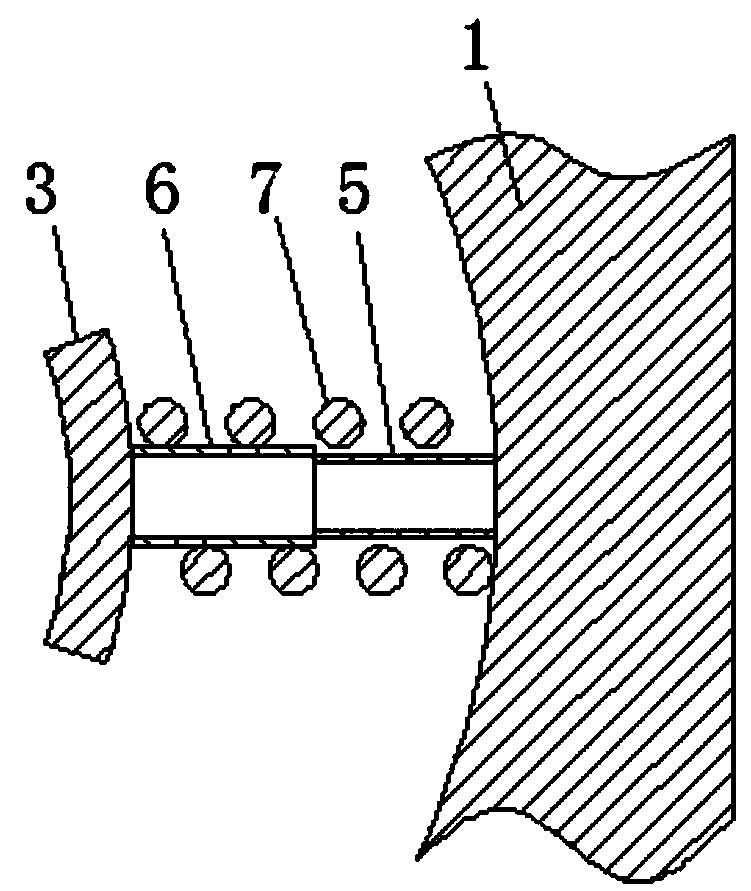

[0035] Such as image 3 As shown, the difference between it and Embodiment 1 is that in this embodiment, there are several fixing parts 4, and the several fixing parts 4 are evenly spaced in the circumferential direction, and two adjacent fixing parts 4 are provided with There is a water storage bag 13; the fixed part 4 is a telescopic rod, and the telescopic rod includes a fixed joint 5 fixedly connected to the inner wall of the cavity 2 and a movable joint 6 sleeved on the fixed joint 5, and the telescopic joint A spring 7 is sleeved on the telescopic rod, and one end of the spring 7 is fixedly connected with the fixed section 5 or the inner wall of the cavity 2 , and the other end is fixedly connected with the movable section 6 .

[0036] The above arrangement enables the battery carrying device 3 to move, so that the shock absorption of the battery 12 can be realized, and the battery 12 can be prevented from being damaged by vibration.

Embodiment 3

[0038] Such as Figure 4 As shown, the difference between it and the second embodiment is that this embodiment provides another shock absorbing structure for the battery 12 of the fixing member 4; the fixing member 4 includes a slide bar, and the inner wall of the cavity 2 is provided with a A spring 7 is connected between the sliding hole 8 and the inner wall of the cavity 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com