Underground branch wiring pipe of buried wire

A technology of branch wiring and ground embedding, which is applied in the direction of cable entry sealing devices and electrical components, can solve the problems of ineffective insulation, increase of ground protrusions, increase of construction difficulty, etc., achieve good insulation treatment effect and reduce emergency repair intensity , The effect of reducing cost and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

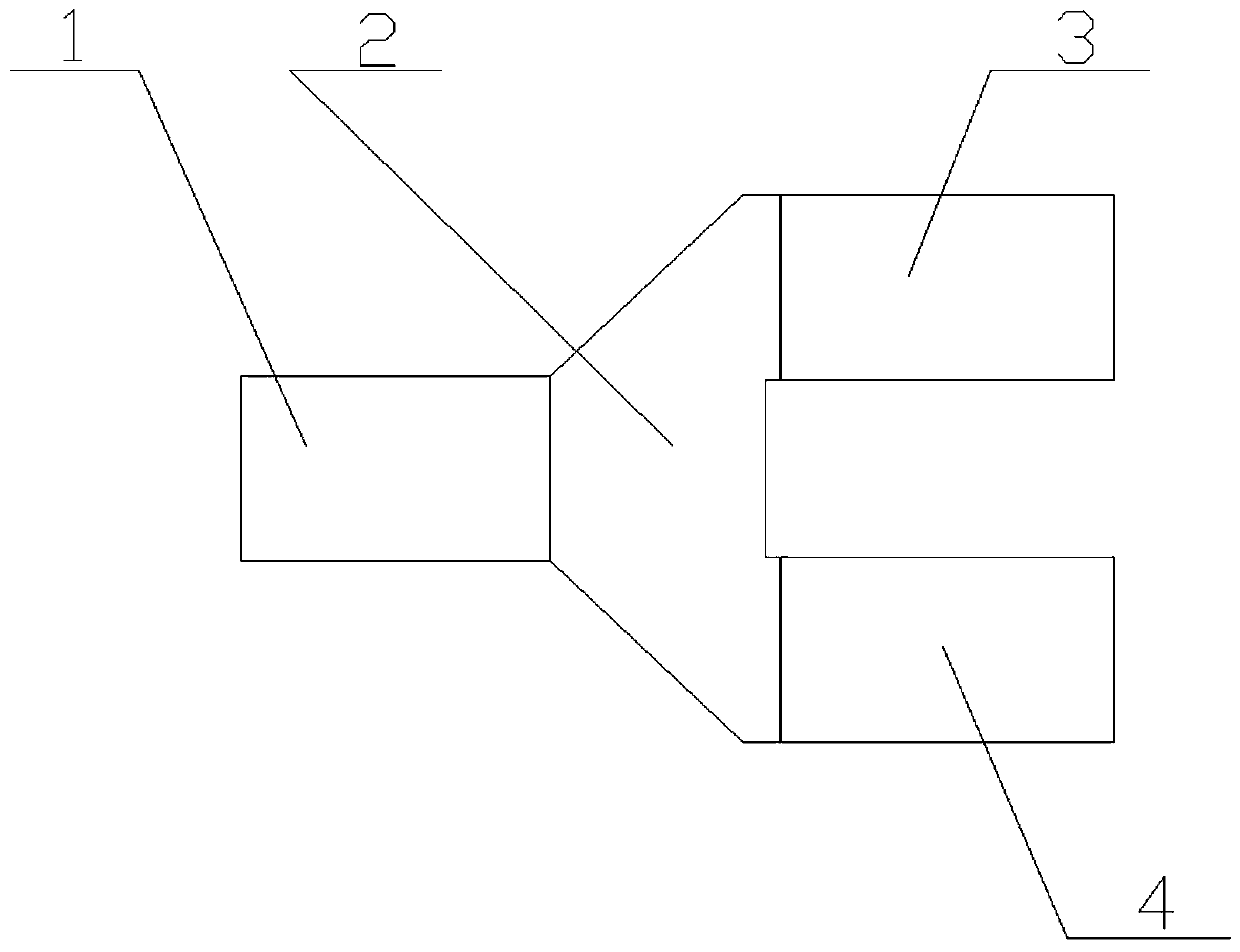

[0046] Such as figure 1 As shown, the present embodiment has an inlet section 1 and an outlet section 4 . The lead-in section 1 is used as the entry end of the buried pipeline, and is connected to the wiring pipe of the previous section. The lead-out section 4 is used as the outlet end of the buried pipeline, and is connected to the wiring pipe at the back. In this embodiment, a trapezoidal connecting portion 2 is provided between the connecting portion 2 communicating with the leading-in section 1 and the leading-out section 4 . The connection part 2 has three openings in total. In addition to connecting the lead-in section 1 and the lead-out section 4 as shown in the figure, it is also connected with a branch section 3, and the branch section 3 serves as a protection tube for the branch line. Since the connecting portion 2 is trapezoidal, the branch section 3 and the lead-out section 4 can be arranged in parallel, which is suitable for wiring where the direction of the bra...

Embodiment 2

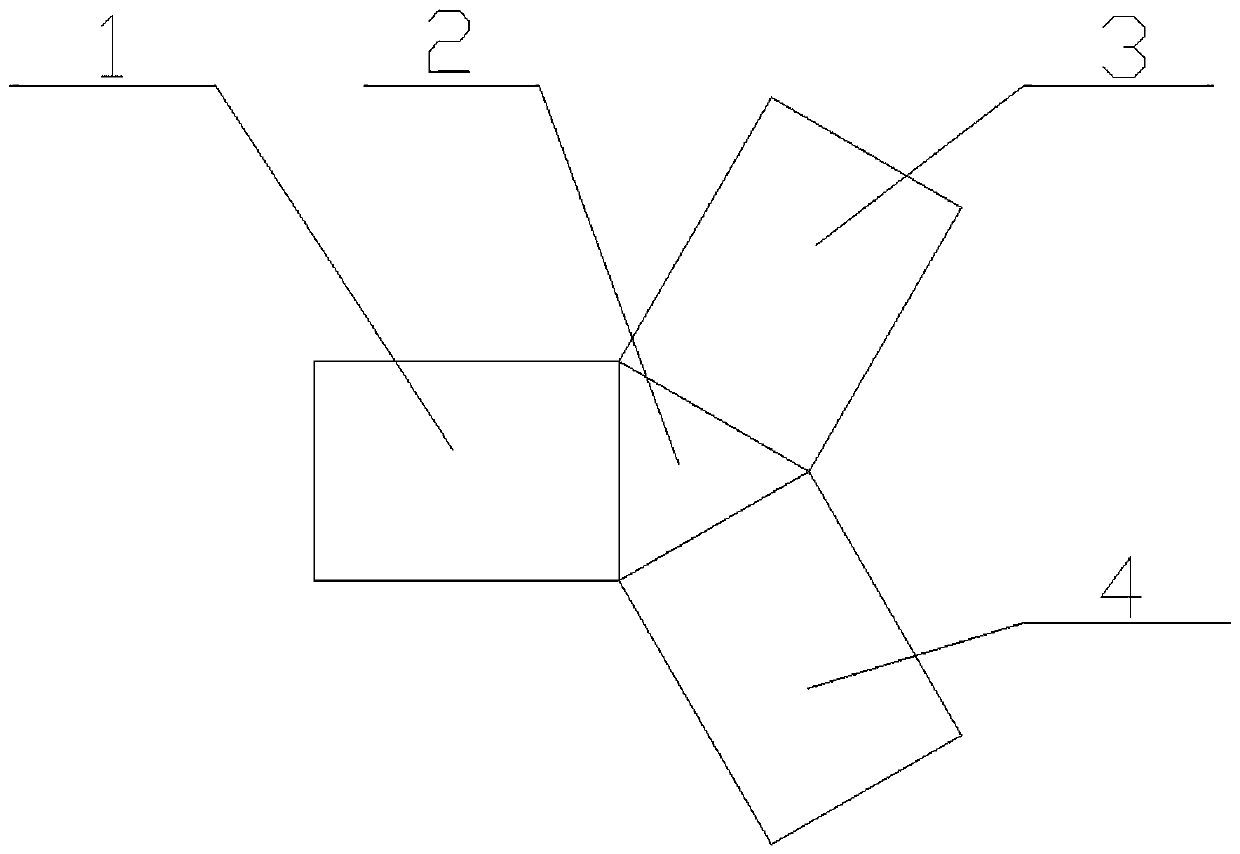

[0048] Such as figure 2 As shown, the present embodiment has an inlet section 1 and an outlet section 4 . The lead-in section 1 is used as the entry end of the buried pipeline, and is connected to the wiring pipe of the previous section. The lead-out section 4 is used as the outlet end of the buried pipeline, and is connected to the wiring pipe at the back. In this embodiment, a triangular connecting portion 2 is provided between the connecting portion 2 communicating with the leading-in section 1 and the leading-out section 4 . The connection part 2 has three openings in total. In addition to connecting the lead-in section 1 and the lead-out section 4 as shown in the figure, it is also connected with a branch section 3, and the branch section 3 serves as a protection tube for the branch line. Since the connecting part 2 is triangular, the branch section 3, the lead-out section 4 and the lead-in section 1 can be arranged at different angles, which is suitable for wiring sit...

Embodiment 3

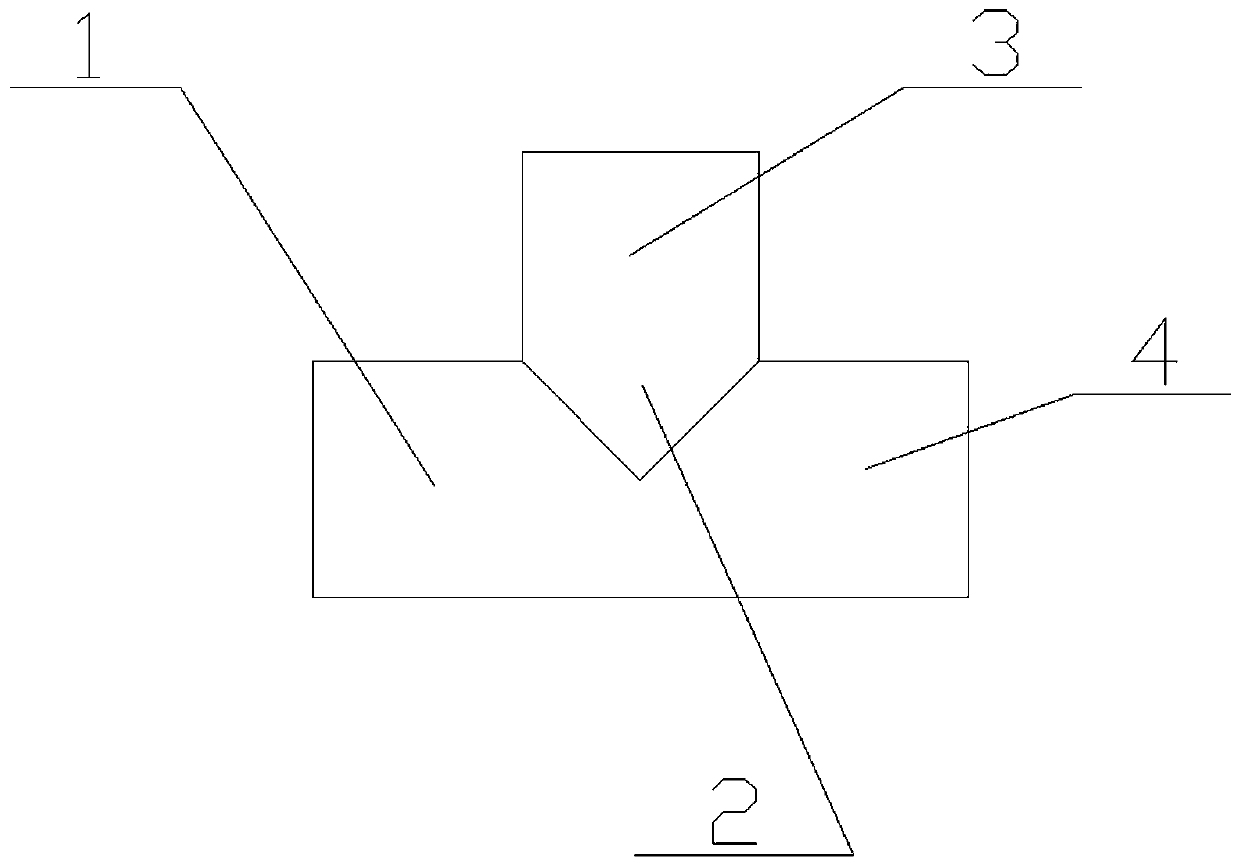

[0050] Such as image 3 As shown, the present embodiment has an inlet section 1 and an outlet section 4 . The lead-in section 1 is used as the entry end of the buried pipeline, and is connected to the wiring pipe of the previous section. The lead-out section 4 is used as the outlet end of the buried pipeline, and is connected to the wiring pipe at the back. In this embodiment, a wedge-shaped connecting portion 2 is provided between the connecting portion 2 communicating with the leading-in section 1 and the leading-out section 4 . The wedge-shaped connection part 2 has only two openings, and since the lead-in section 1 and the lead-out section 4 form a straight pipe, the wedge-shaped connection part 2 is inserted into the straight pipe and connected with a branch section 3 as a protection pipe of a branch circuit. This shape of underground branch conduit for buried wires is suitable for the case where the wiring with a very different angle from the aforementioned direction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com