Switched reluctance motor

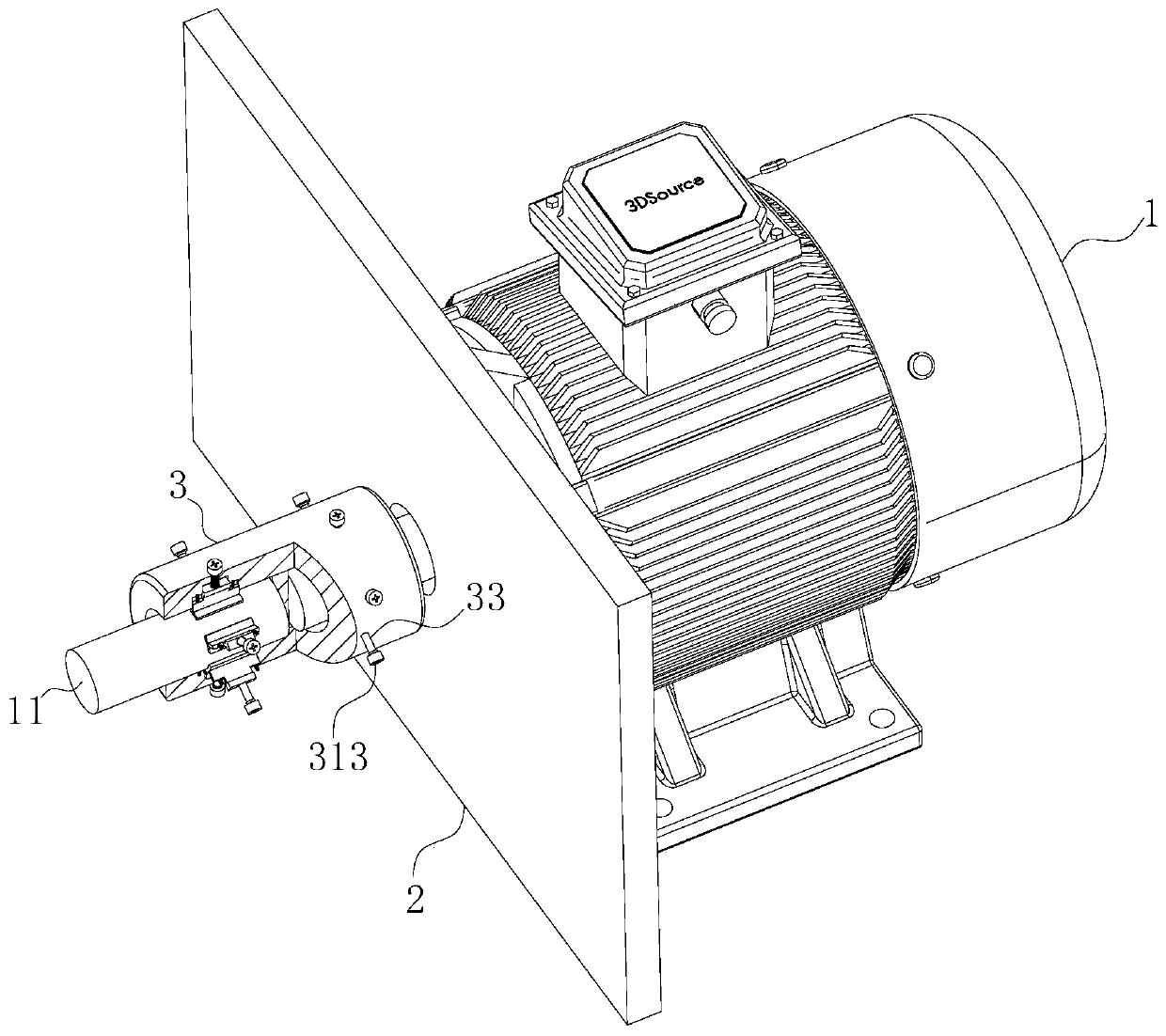

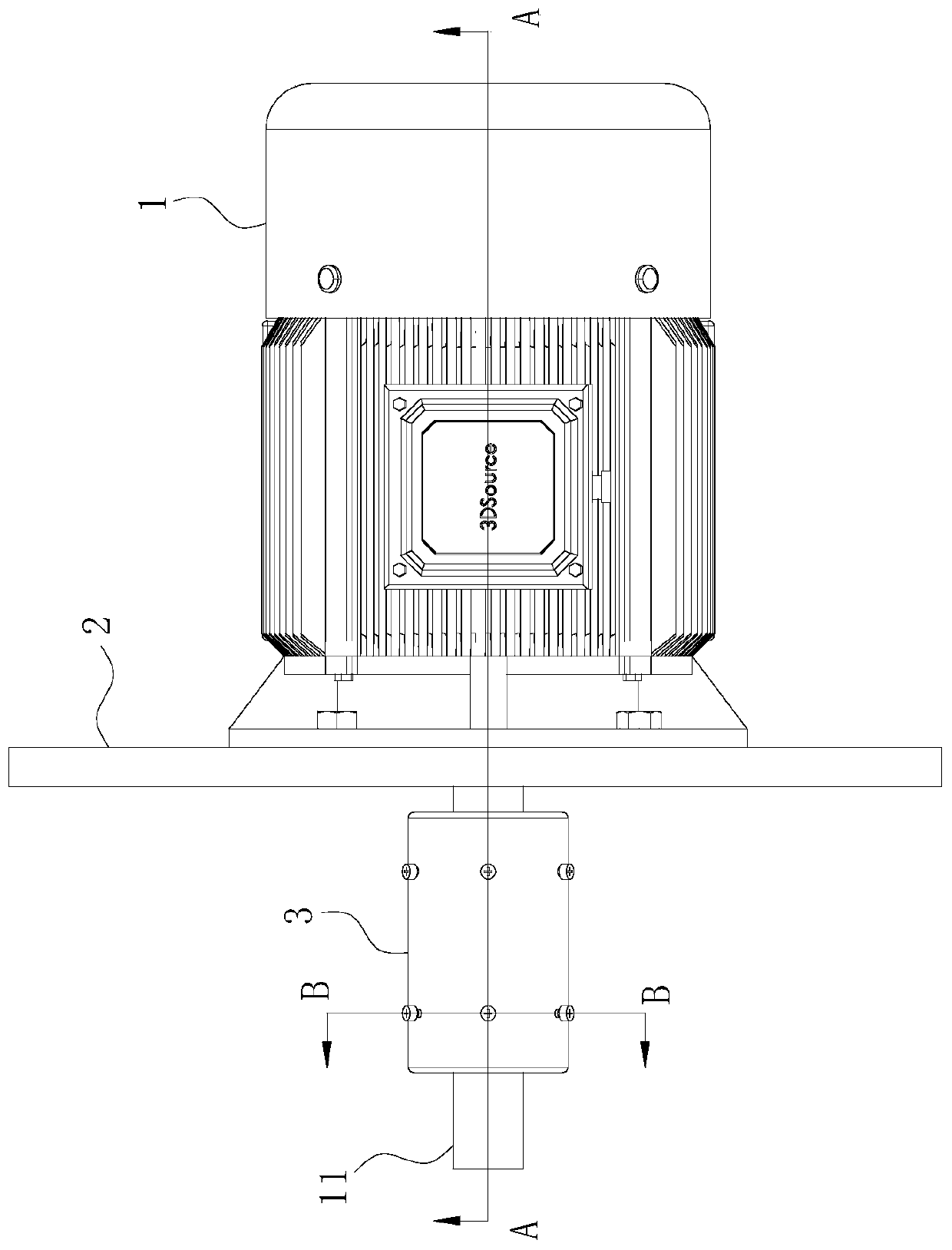

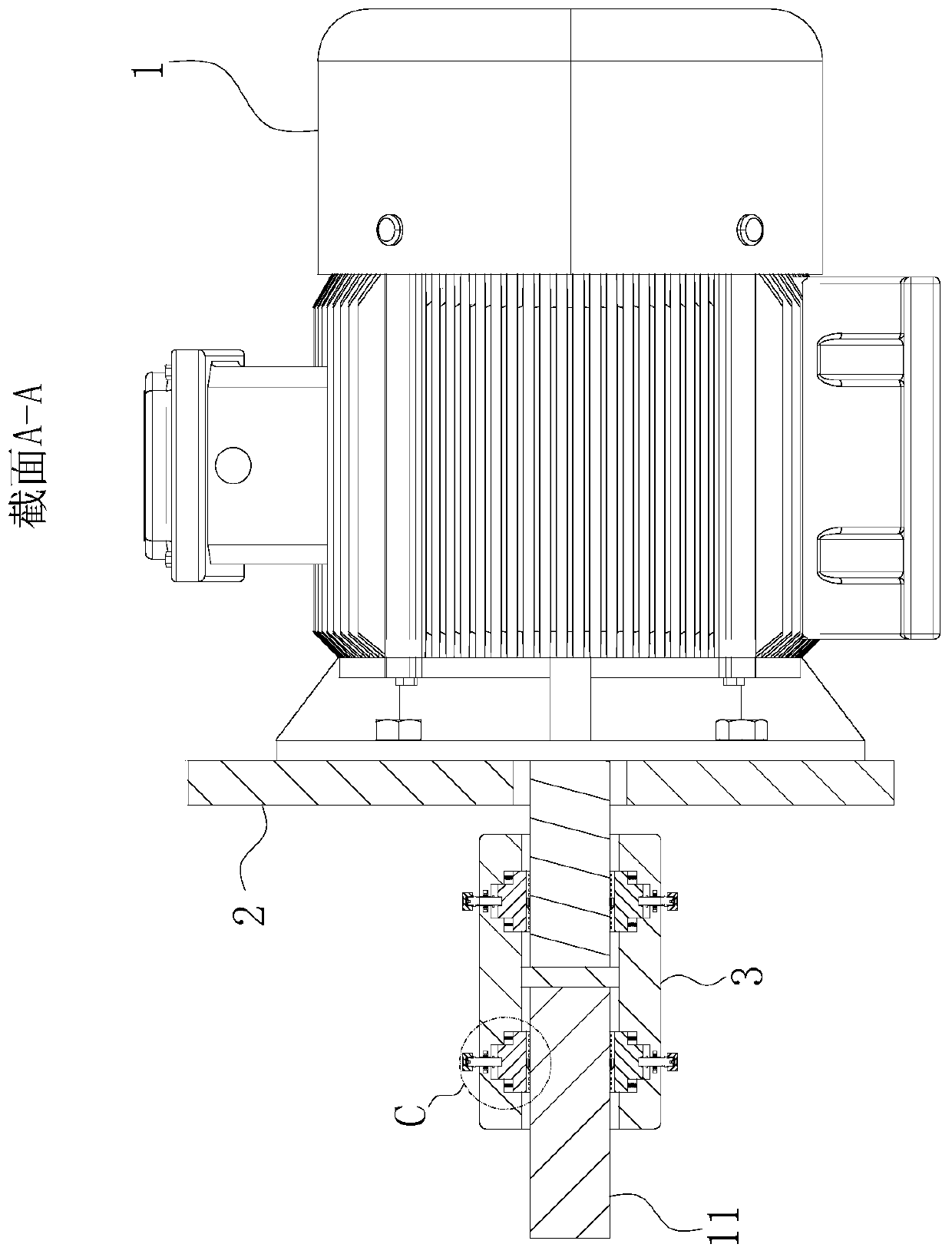

A technology of switched reluctance motor and motor body, which is applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., which can solve the problems of poor coaxiality, output shaft disassembly damage, energy loss, etc., and reduce the poor coaxiality of connections , fast and easy disassembly, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] As an embodiment of the present invention, the fixing plate 32 is provided with a second installation groove on one side of the output shaft or the transmission shaft 11 of the motor body 1; block 37; the first telescopic rod 38 is fixedly connected between the briquetting block 37 and the groove bottom of the corresponding second installation groove, and the piston rod of the first telescopic rod 38 and the corresponding briquetting block 37 are fixed to each other. connection; the connecting sleeve 3 is provided with evenly arranged limiting grooves at the positions of the threaded adjustment holes; the inside of the limiting grooves are all slidably connected to the limiting block 39; the limiting block 39 and the groove of the corresponding limiting groove The positions between the bottoms are fixedly connected with the second telescopic rods 310, and the second telescopic rods 310 and the corresponding first telescopic rods 38 are connected to each other; when worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com