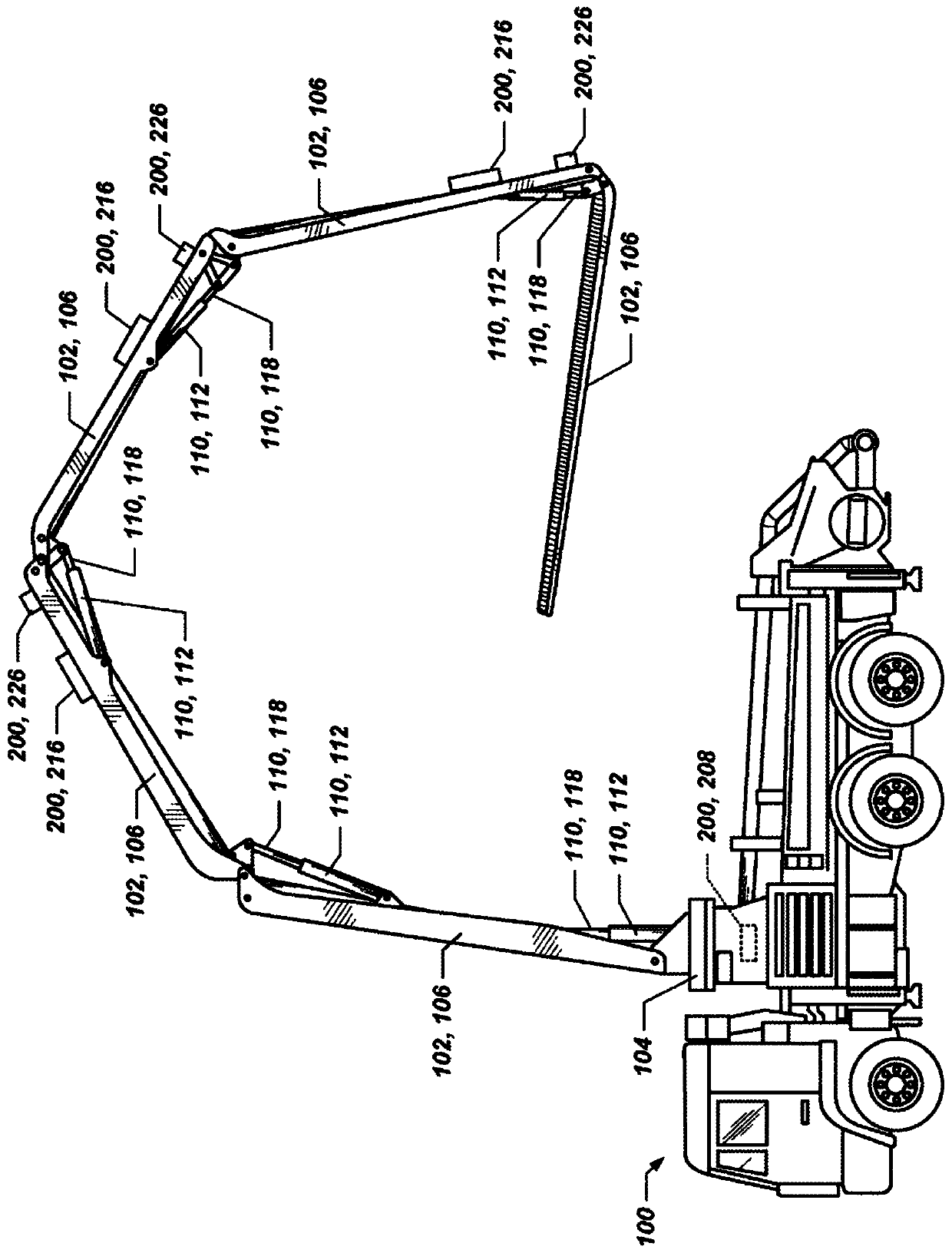

System with motion sensors for damping mass-induced vibration in machines

A motion sensor, mass technology, applied in the field of hydraulic system, can solve problems such as not very effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

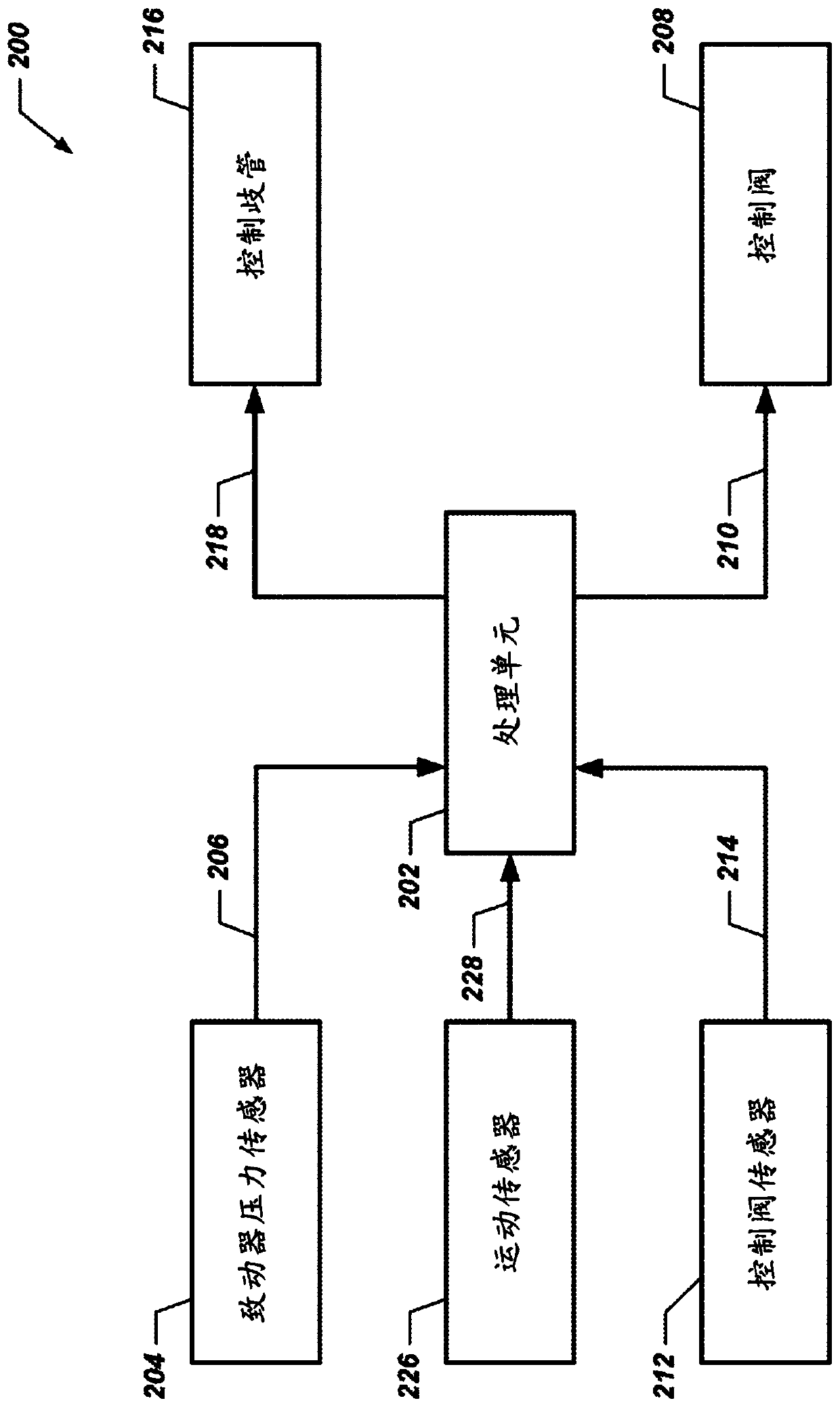

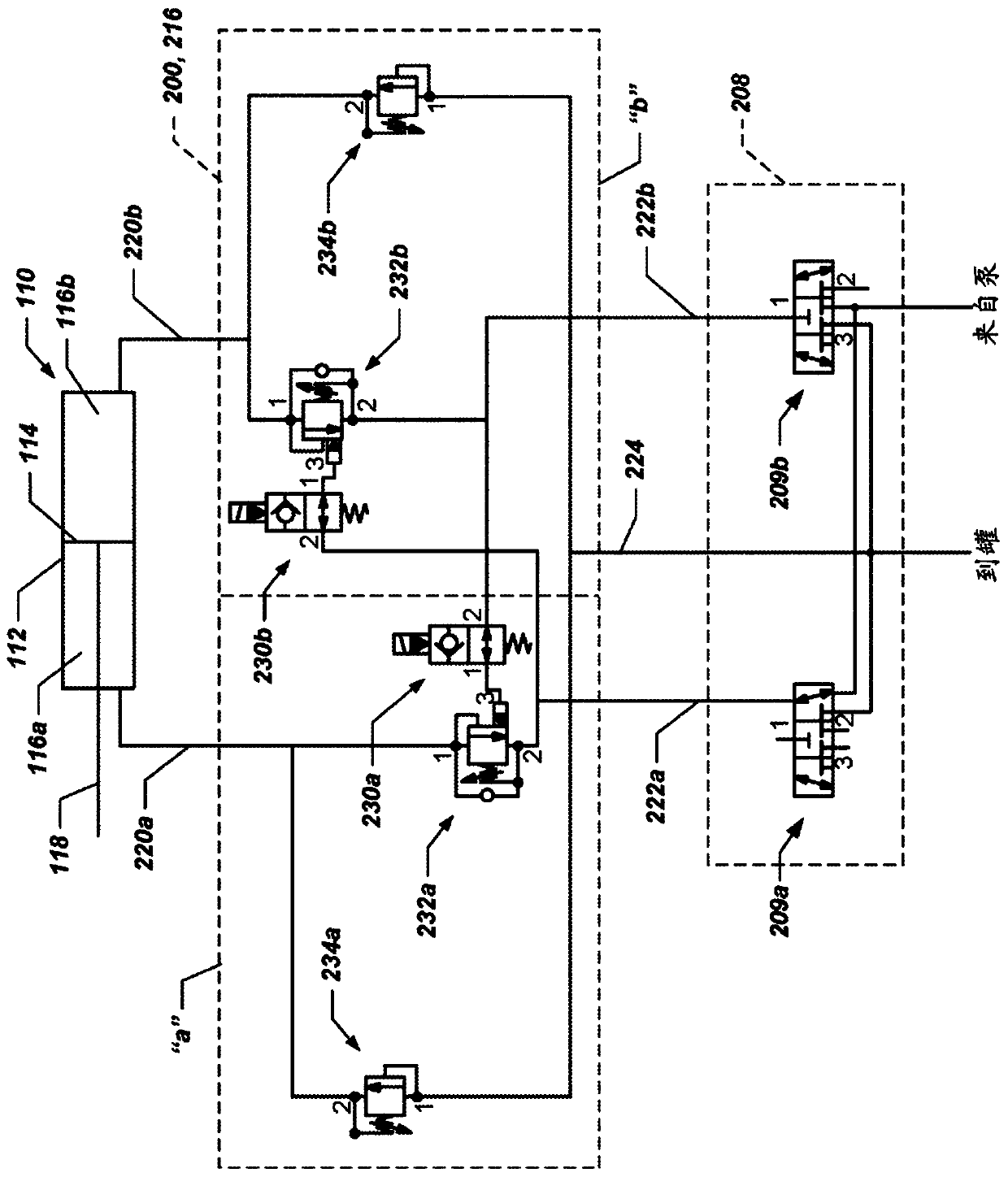

[0040] Example 1. In conjunction with or independently of any of the embodiments disclosed herein, there is provided an apparatus for dampening mass-induced vibration in a machine, the apparatus comprising an elongated member and a hydraulic actuator configured to move the elongated member The elongate member has a non-load-holding chamber and a load-holding chamber that includes a motion sensor operable to measure motion of the elongate member caused by mass-induced vibrations. The apparatus includes a plurality of control valve spools operable to supply a variable flow rate of hydraulic fluid to a hydraulic actuator. The apparatus includes a control manifold fluidly interposed between the hydraulic actuator and the plurality of control valve spools. The apparatus includes a processing unit operable with the control manifold to control flow of hydraulic fluid to the hydraulic actuator based at least in part on measurements of motion of the elongate member received from a mot...

Embodiment 2

[0041] Example 2. In conjunction with or independently of any of the embodiments disclosed herein, the motion sensor includes a first motion sensor located at a first location along the elongated member, and the device further includes a first motion sensor located at a second location along the elongated member. Two motion sensors. The second location is different from the first location.

Embodiment 3

[0042] Example 3. In conjunction with or independently of any of the embodiments disclosed herein, the apparatus further includes a plurality of control valve sensors operable to measure the pressure of hydraulic fluid exiting the control valve spool. The control manifold is also operable to control the flow of hydraulic fluid to the hydraulic actuators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com