Method for starting coolant fluid circuit comprising liquid pump

A coolant, circuit technology, used in fluid circulation arrangements, heating/cooling equipment, refrigerators, etc., can solve problems such as frequent maintenance, pump wear, etc., to simplify design and integration, eliminate the risk of wear and damage, pressure drop reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

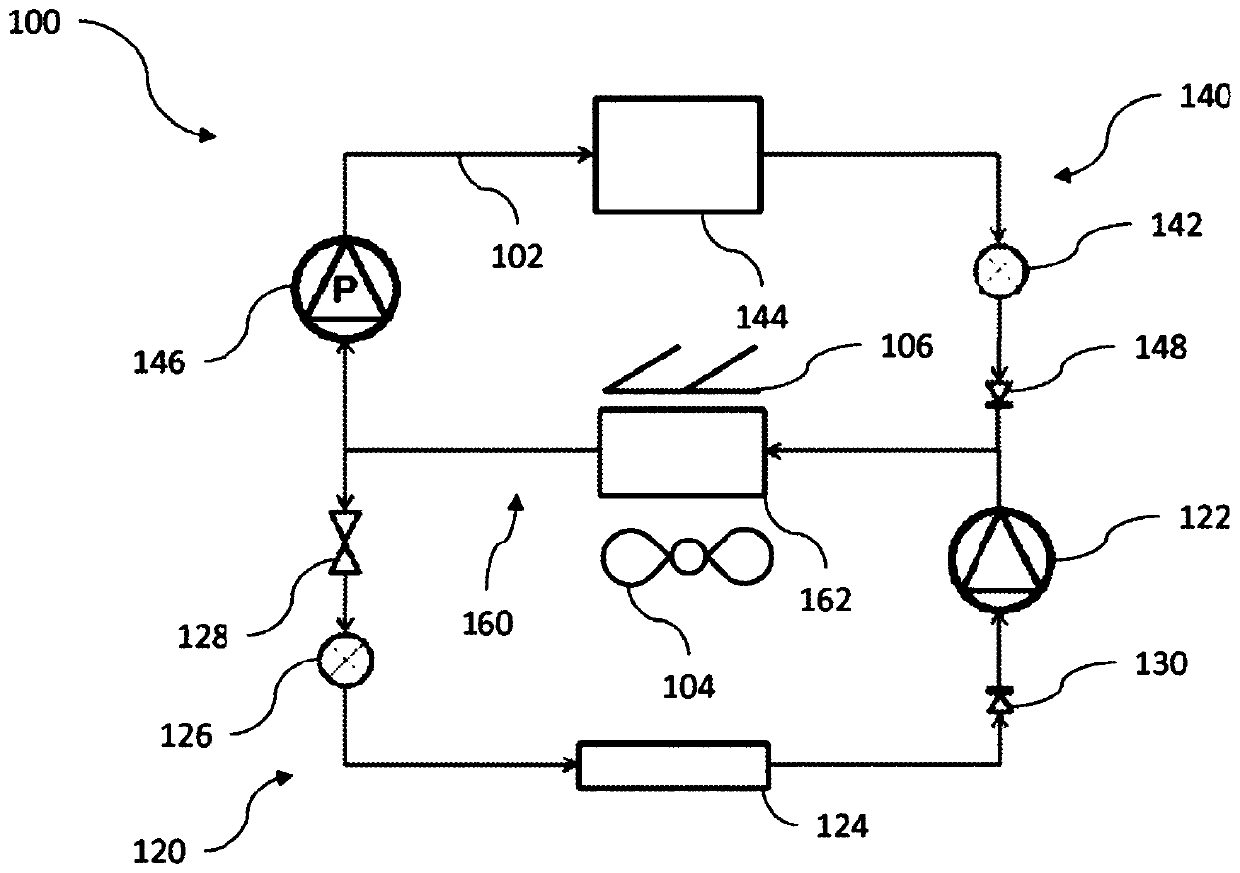

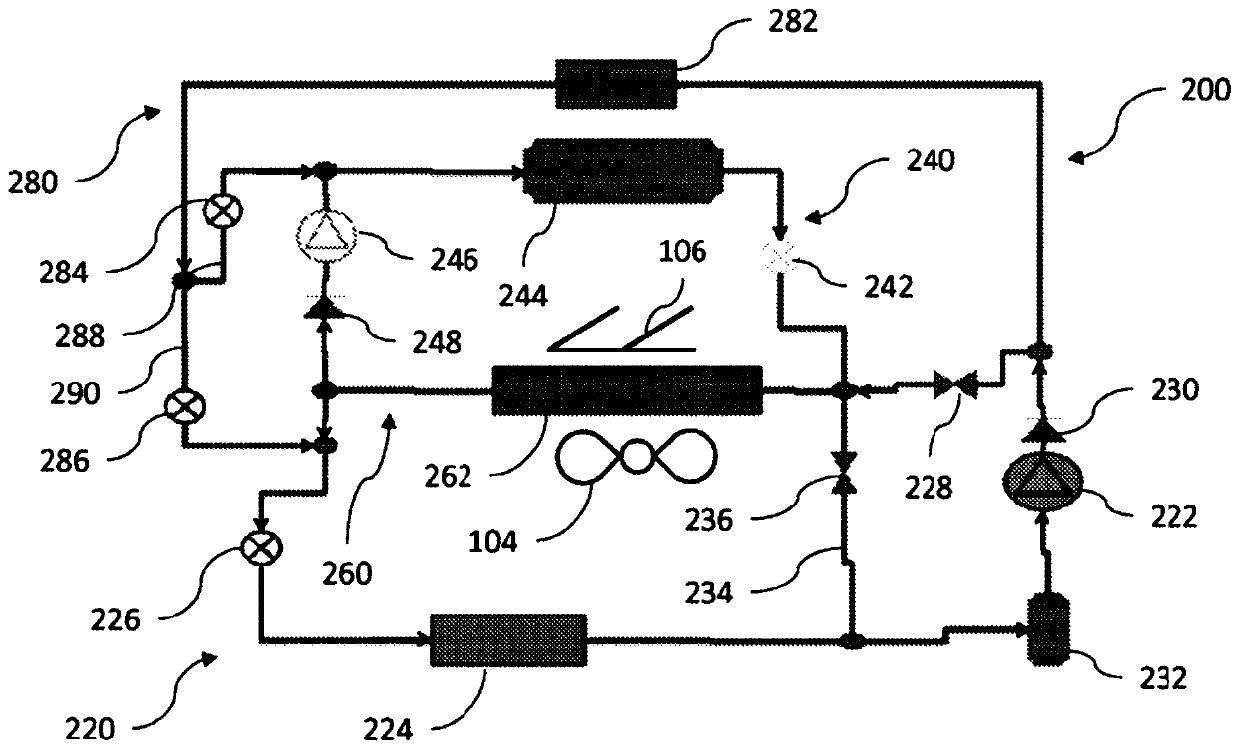

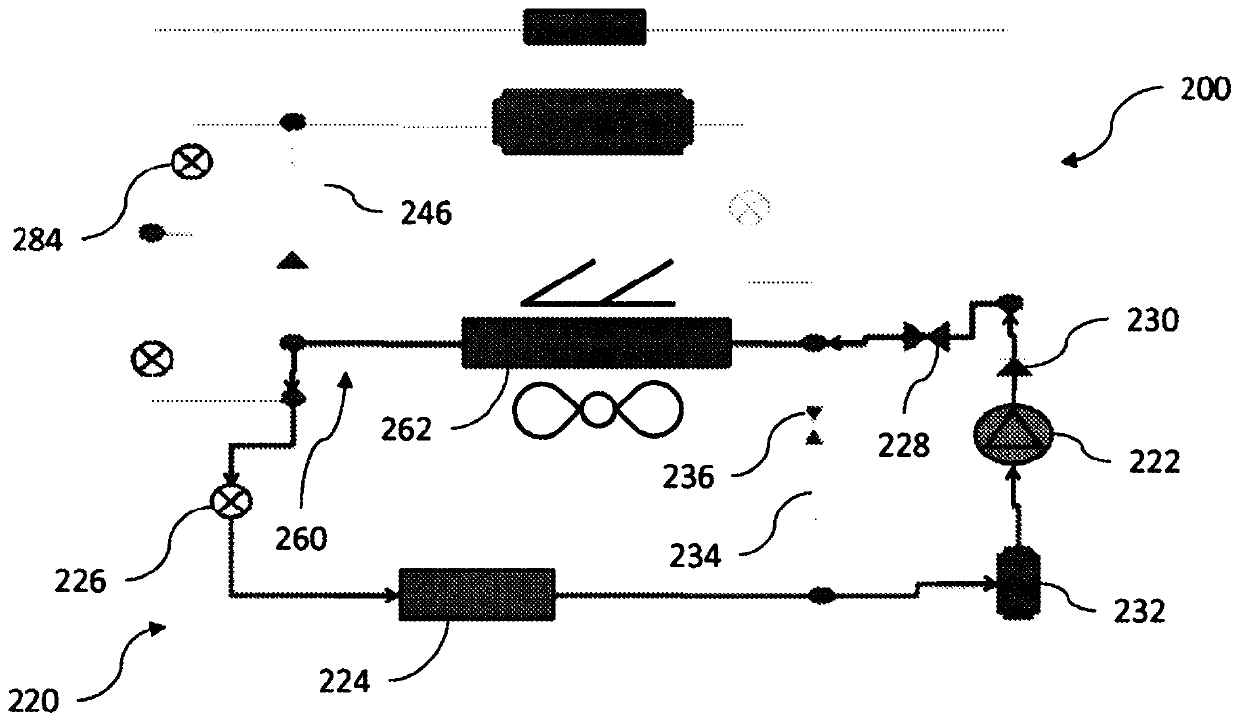

[0052] At the outset, it should be noted that the accompanying drawings disclose the invention in detail for carrying out the invention. Of course, the drawings can be used to better define the invention if necessary.

[0053] In the remainder of the description, the terms upstream and downstream are used to describe the arrangement of components with respect to the flow direction of the fluid under consideration. Similarly, the arrangement of the constituent elements of a fluid circuit is provided with respect to the direction of flow of the fluid in the circuit.

[0054] An element described hereinafter as being located between two other elements does not mean that the element is physically located between the other two elements, but that the fluid passes first through one of the two elements and then through the element under consideration .

[0055] Throughout this specification, some elements or parameters may be referenced, such as a first element or a second element a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com