Whole goose marinating process and marinating equipment thereof

A process and equipment technology, which is applied in the field of whole goose marinating process and its marinating equipment, can solve the problems of unpalatable taste, stagnant marinade, rough process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

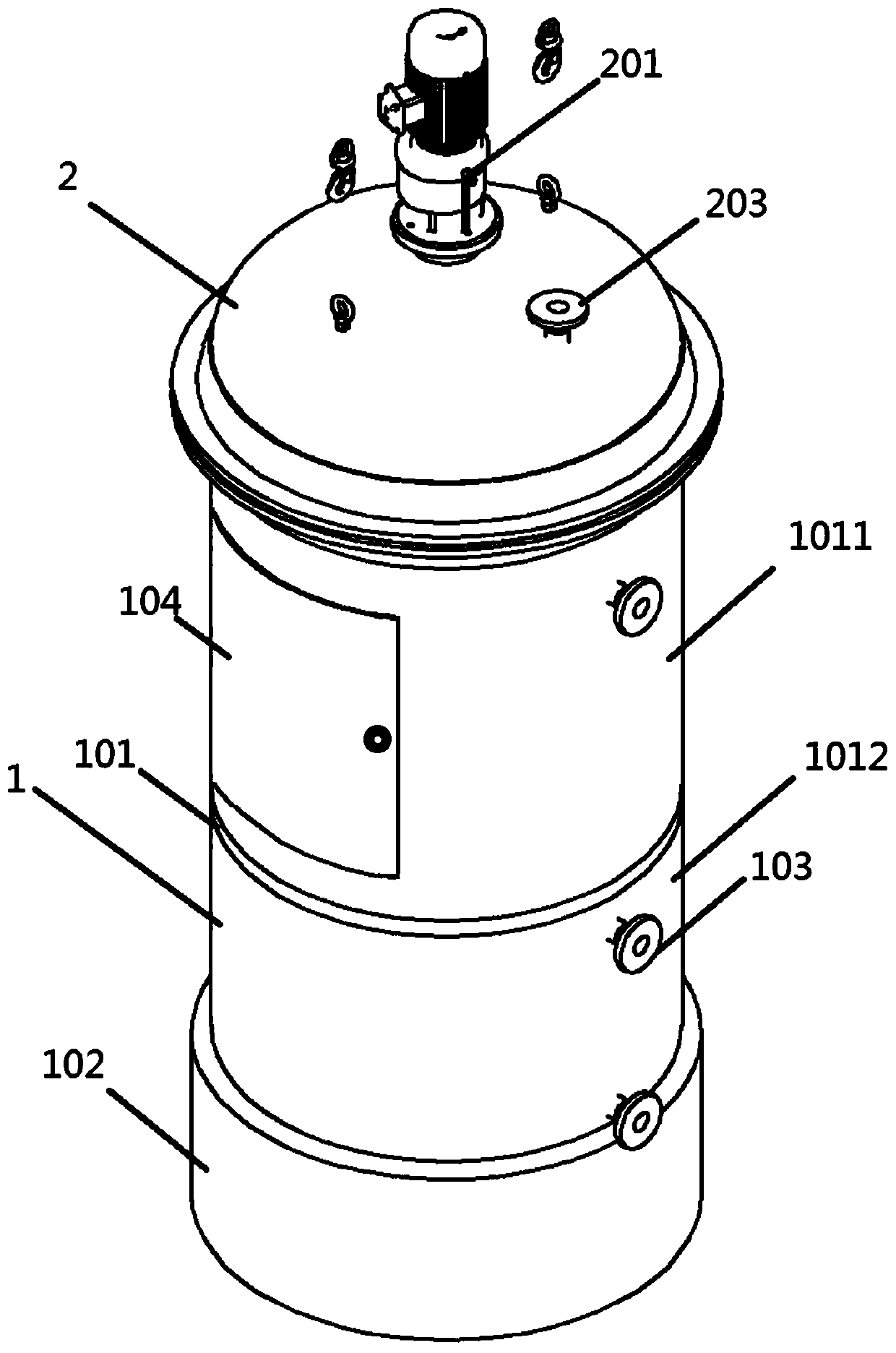

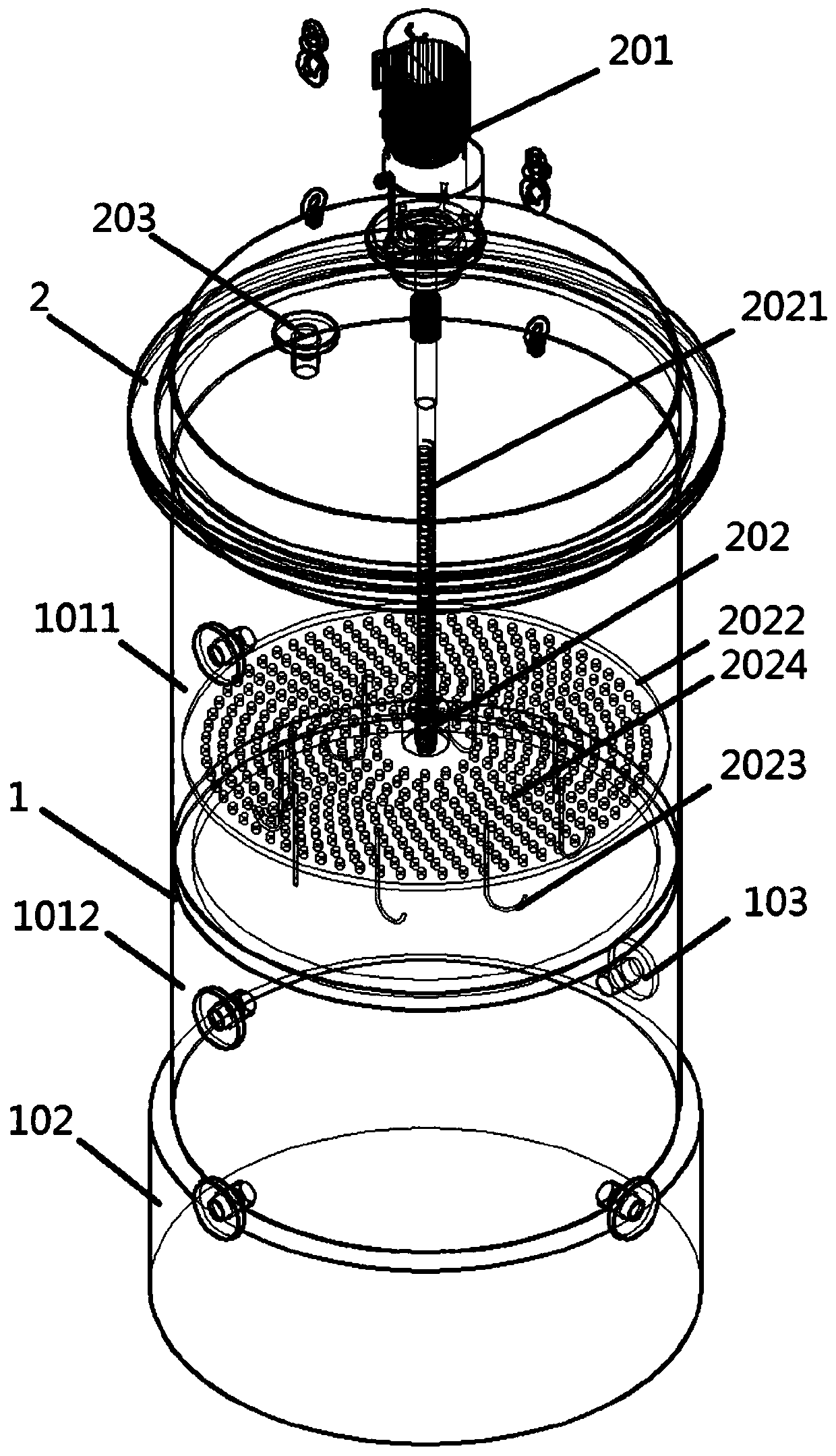

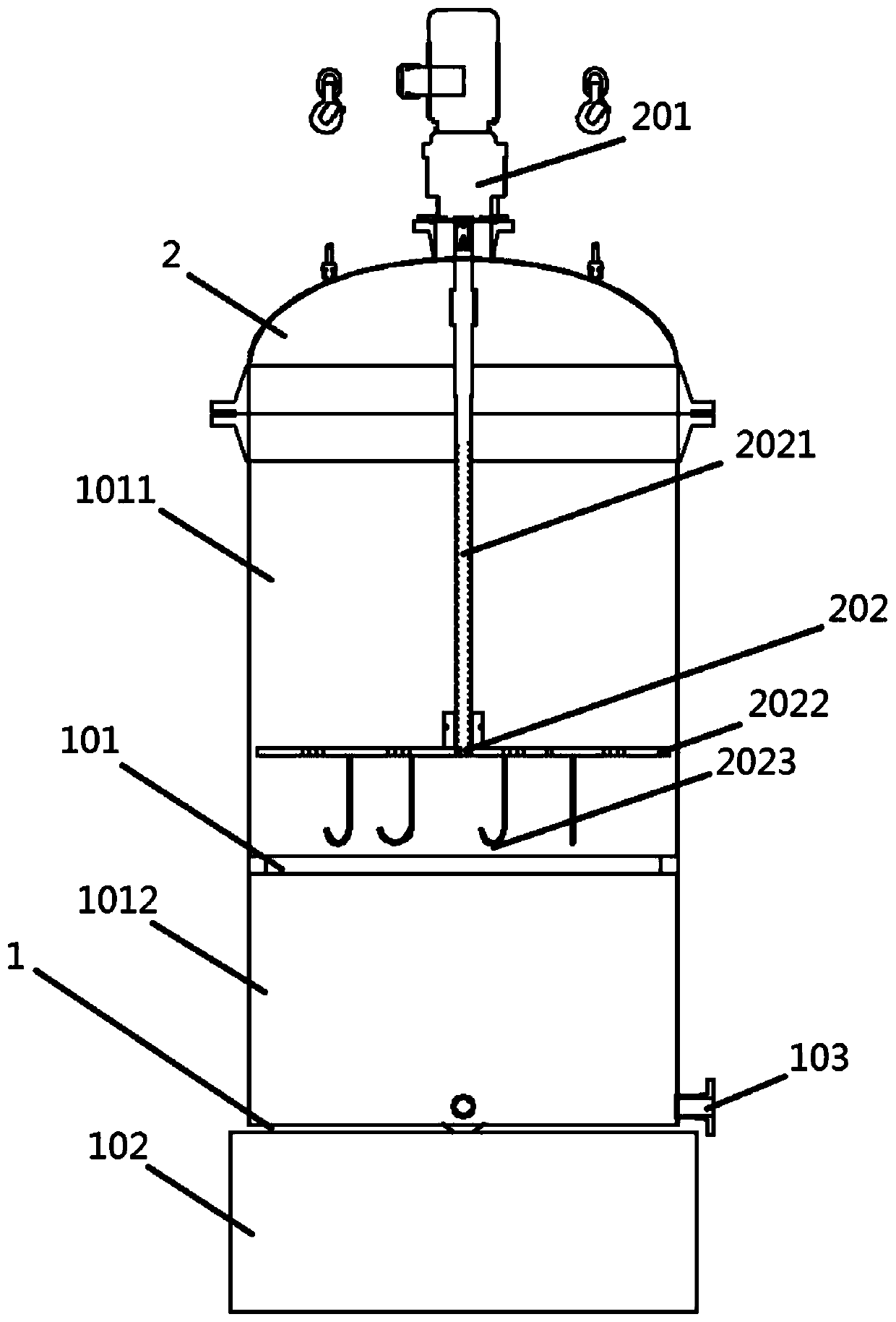

[0065] like figure 1 , figure 2 , image 3 As shown, a halogenated device includes a housing 1 and a cover 2 . A brine zone 101 and a heating zone 102 are set inside the housing 1. The brine zone 101 includes a draining zone 1011 and a brine zone 1012. The brine zone 1012 is set above the heating zone 102, and the draining zone 1011 is set above the brine zone 1012. The casing is also provided with a circulation hole 103 and a casing door 104 . A lifting mechanism 201 is arranged on the cover body 2, and the lifting mechanism 201 is connected to the hanging object lifting part 202. The hanging object lifting part 202 includes a screw shaft 2021 and a lifting plate 2022. A hook 2023 is also arranged on the lift plate 2022 . A plurality of filter holes 2024 are evenly distributed on the surface of the lift plate 2022 . The cover body 2 is also provided with a vent hole 203 .

[0066] This equipment is not only suitable for marinating whole goose, but also for marinating o...

Embodiment 2

[0068] A whole goose stewed process comprises the steps of:

[0069] A4. After the treatment of A3, spread the inside and outside of the goose evenly with spice powder, bind and fix the goose’s wings entrained with the spice powder, and marinate for 20-30 minutes. The spice powder includes: The following components: star anise 25-30g, grass fruit 10-20g, cinnamon 15-30g, rosemary 5-7g;

[0070] A. Pretreatment of whole goose:

[0071] A1. Select lion head geese with an age of 95d-105d, keep the geese intact, clean them after slaughtering, and set aside.

[0072] A2. After the treatment of A1, cool the lion's head goose in cold water below 10°C; boil the rosin glyceride, cool the lion's head goose and quickly immerse in the rosin glyceride and roll for 3 to 5 weeks; then put it again In cold water, cool the rosin glyceride and peel it off; then use small pliers to pull out the fine hairs; the rosin glyceride is edible grade rosin glyceride.

[0073] A3. After the treatment o...

Embodiment 3

[0081] Braised goose taste sensory triangle test:

[0082] Get the sample of this craft product as A sample, the sample of commercially available product is B sample, the probability that two kinds of samples occur in sensory triangle test is equal, according to the permutation and combination of two kinds of samples (ABB, BAA, ABA, BBA, AAB , BAB) look up the random number table to code each possible combination, and arrange 12 professional sensory testers to conduct the tasting test. All the samples are whole geese, which are cut into suitable sizes by the same craftsman while keeping all the parts of the whole goose, and are eaten by sensory testers freely. Sensory testers answer the random number codes of samples with sensory differences after tasting food, describe the sensory, and fill out the evaluation form. (Before the sensory test, the sample number appears as a random number, and the test personnel shall not be informed of the specific combination of A and B sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com