Insulating roof using waste foam plastics and its construction method

A heat insulation layer and construction method technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as unsatisfactory heat insulation effects, poor heat insulation performance, and large laying thickness , to achieve the effect of solving the problem of roof heat insulation, small thermal conductivity, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

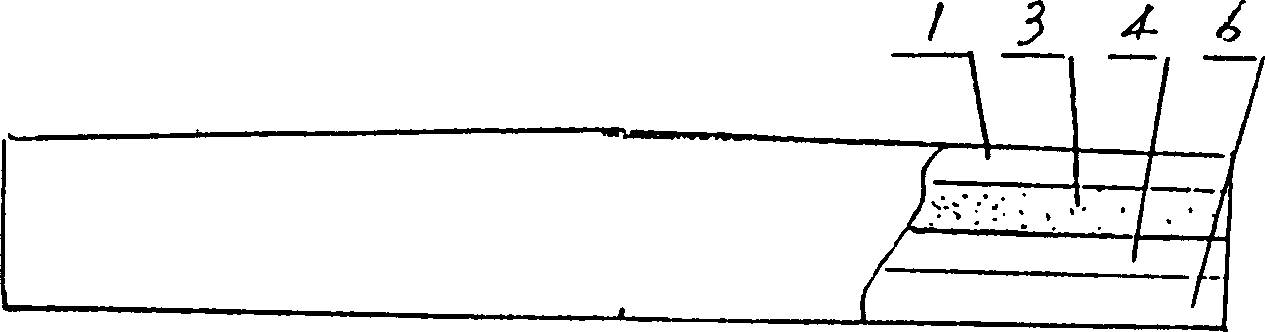

[0013] Waste foam plastic insulation layer flat roof (see figure 1 ) includes a load-bearing base layer 6, an air barrier layer 4, a thermal insulation layer 3 and a waterproof layer 1, the thermal insulation layer 3 is laid on the air barrier layer 4, and the waterproof layer 1 is covered on the thermal insulation layer 3.

Embodiment 2

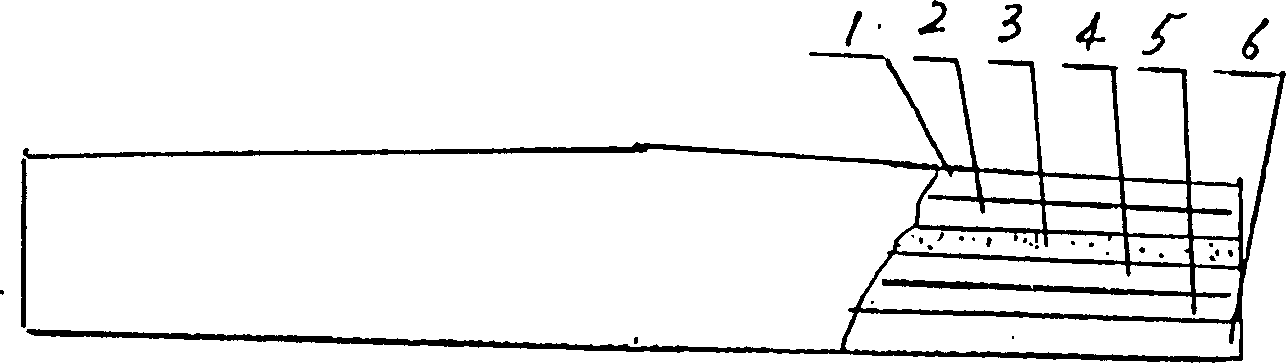

[0015] The difference with embodiment 1 is: there is also a leveling layer 5 between the load-bearing base layer 6 and the air barrier layer 4 (see figure 2 ), there is also a leveling layer 2 between the thermal insulation layer 3 and the waterproof layer 1.

Embodiment 3

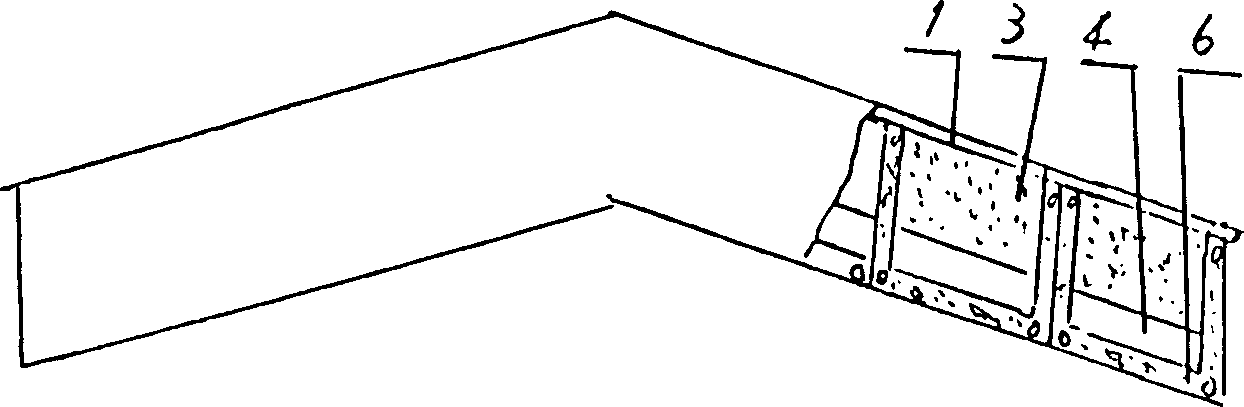

[0017] Waste foam plastic heat insulation layer sloping roof (see image 3 )’s load-bearing base 6 is a reinforced concrete prefabricated hanging tile board, and an air barrier layer 4 is laid in the groove of the hanging tile board, and a foam plastic heat insulation layer 3 is laid on the air barrier layer 4, and a waterproof layer 3 is laid on the foam plastic heat insulation layer 3. Layer, waterproof layer 1 is hanging tiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com