Bimetal composite inner sleeve, bimetal composite outer sleeve and manufacturing method thereof

A composite jacket and bimetal technology, applied in the field of construction machinery, can solve the problems of short life, poor wear resistance, etc., and achieve the effect of improving the overall life, wear resistance, and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

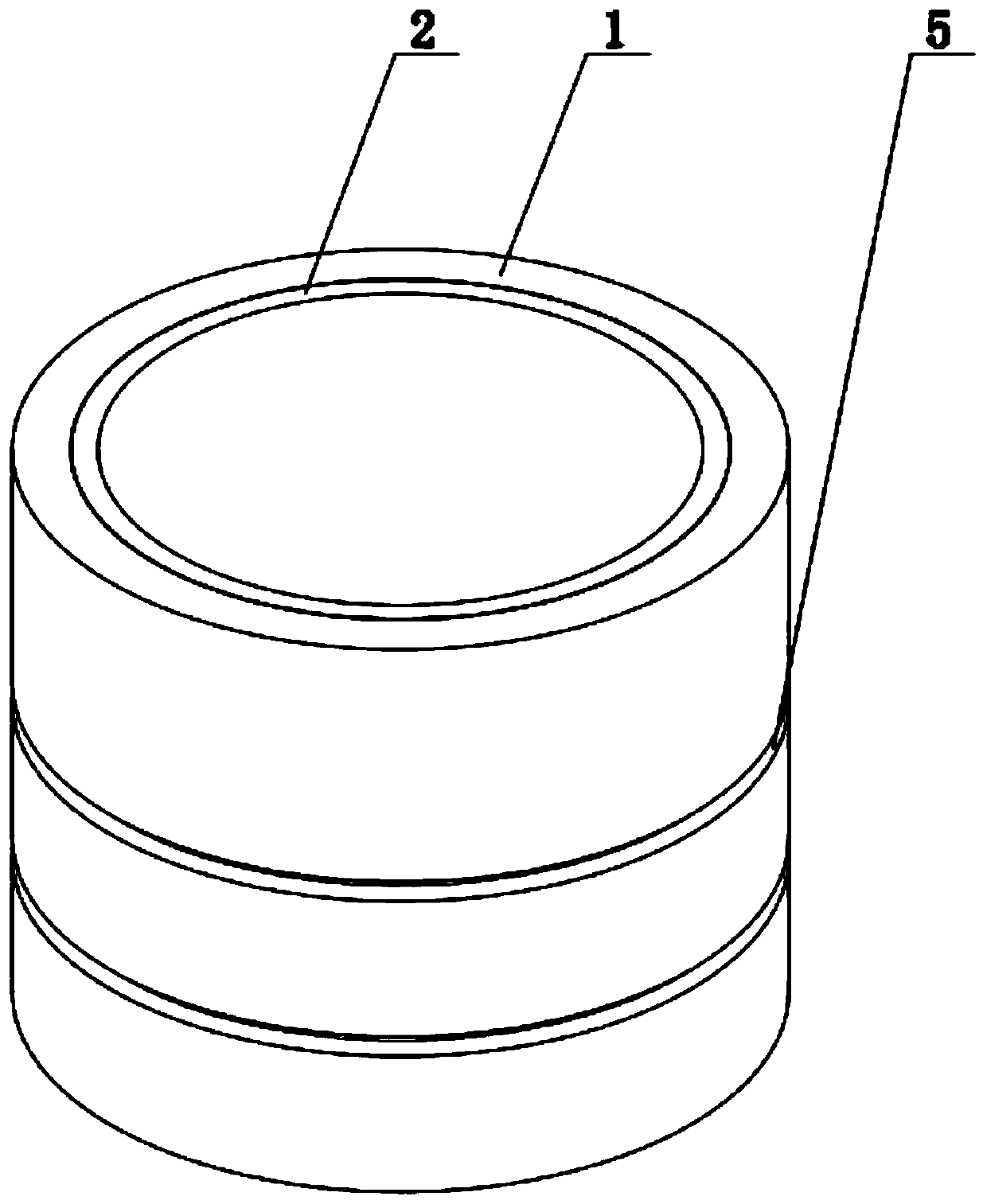

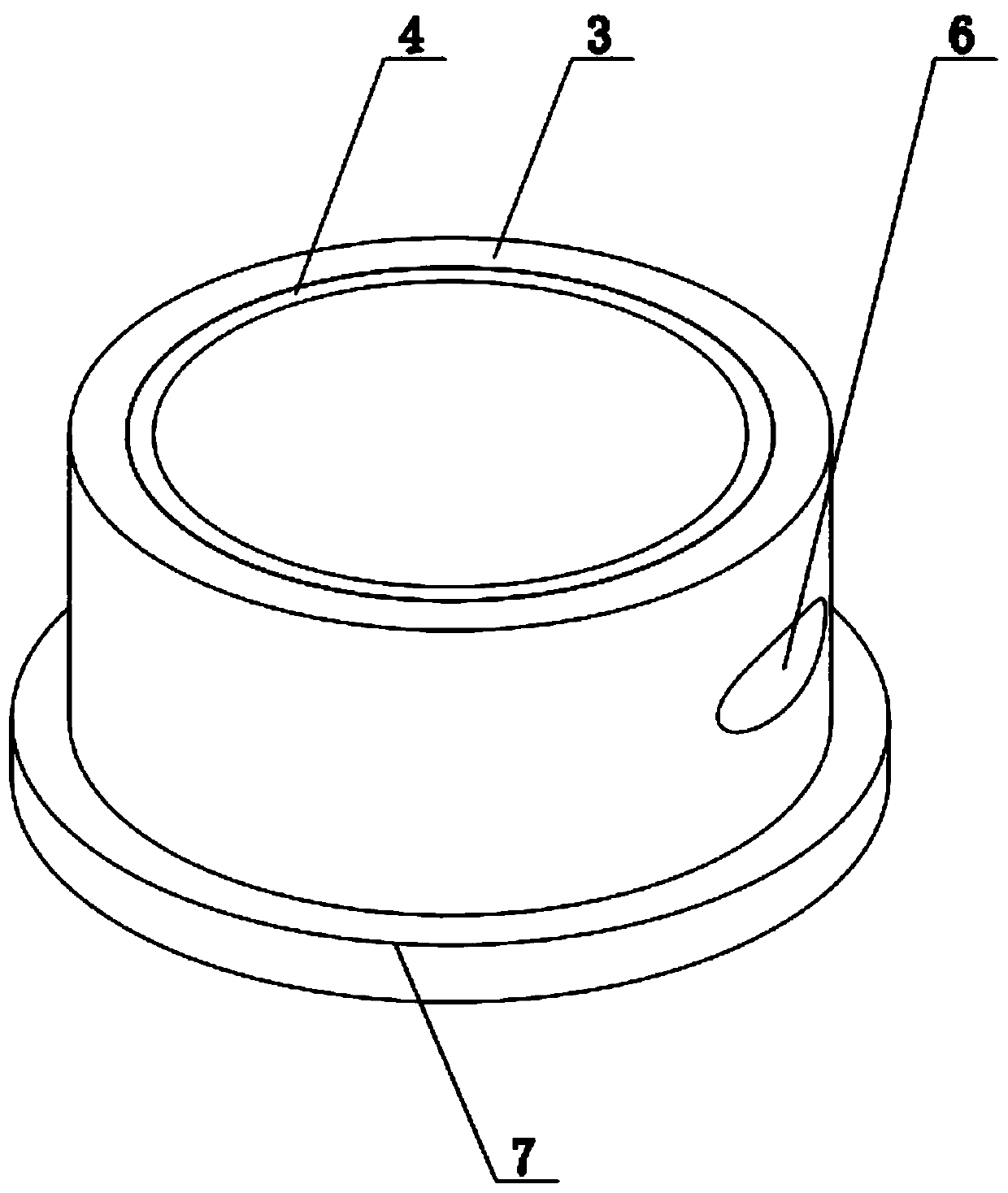

[0029] A bimetal composite inner sleeve, comprising an inner sleeve body, characterized in that: the inner sleeve body includes an inner sleeve outer layer 1 and an inner sleeve inner layer 2, and the inner sleeve inner layer 2 is welded to the inner sleeve by metal welding The outer layer 1 is integrally formed.

Embodiment 2

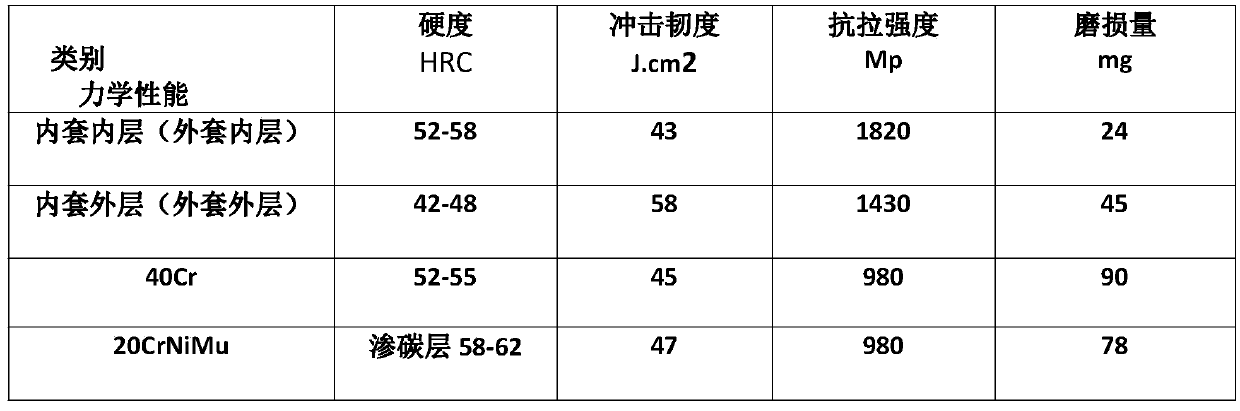

[0031] A bimetal composite inner sleeve, the material of the inner layer 2 of the inner sleeve is calculated by weight percentage, and its composition is: C: 0.3-0.45%, Cr: 12-18.5%, Mn: 0.3-0.7%, V: 0.18 -0.26%, Si: 0.2-0.9%, Mo: 0.6-1.5%, S: ≤0.03%, P: ≤0.04%, Nb: 0.06-0.2%, N: ≤0.4%, Ni: 0.5-1.5%, The rest is Fe and unavoidable impurities; the material of the outer layer 1 of the inner sleeve is calculated by weight percentage, and its composition is: C: 0.2-0.3%, Cr: 5-7.5%, Mn: 0.3-0.6%, Si: 0.2-0.9%, Mo: 0.3-0.7%, S: ≤0.03%, P: ≤0.04%, Nb: 0.06-0.1%, N: ≤0.4%, Ni: ≤0.4%, the rest is Fe and unavoidable Impurities; Other structures are the same as in Example 1.

Embodiment 3

[0033]A bimetal composite sleeve, the thickness of the inner layer 2 of the inner sleeve is 2mm-4mm; other structures are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com