Grinding device for production and processing of stainless steel product

A stainless steel and product technology, applied in large fields, can solve the problems of polluting the workshop environment, time-consuming and laborious, and dust diffusion, and achieve the effects of simple operation, convenient use, and improved production and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

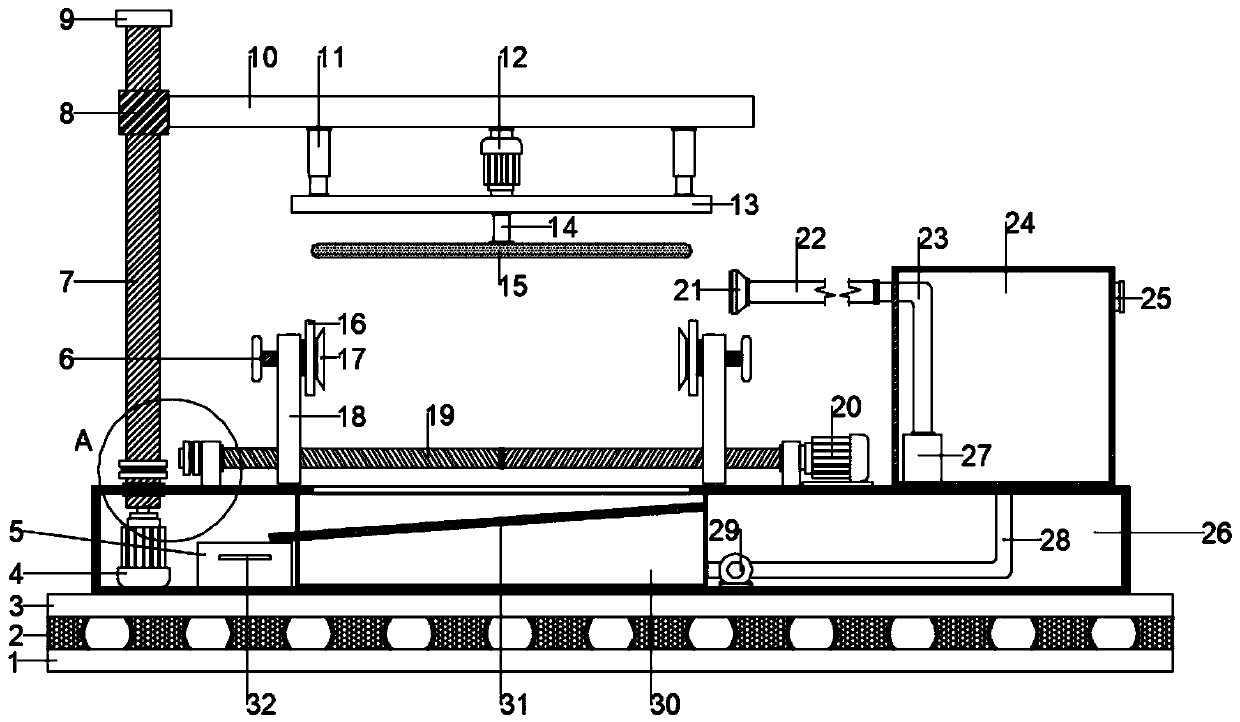

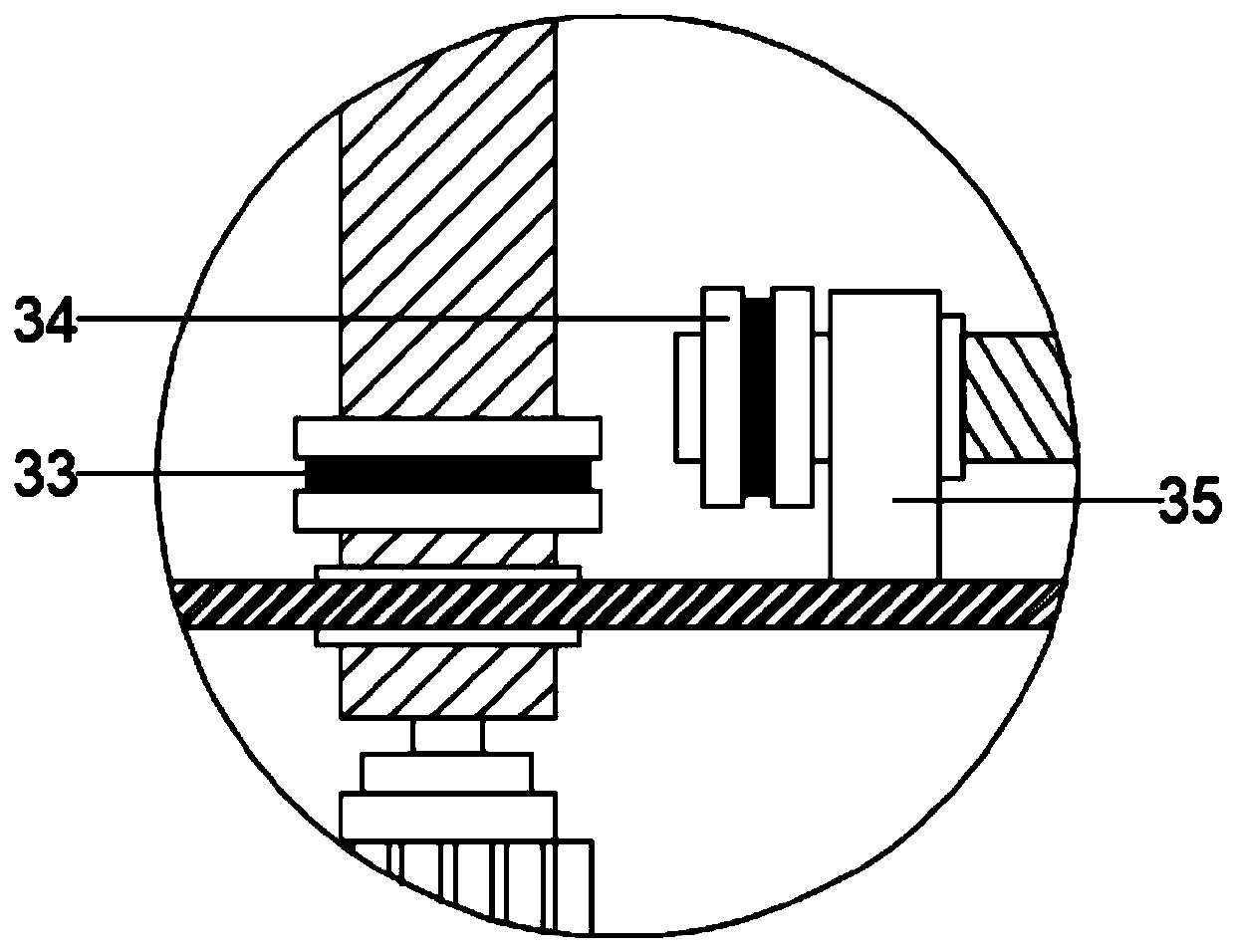

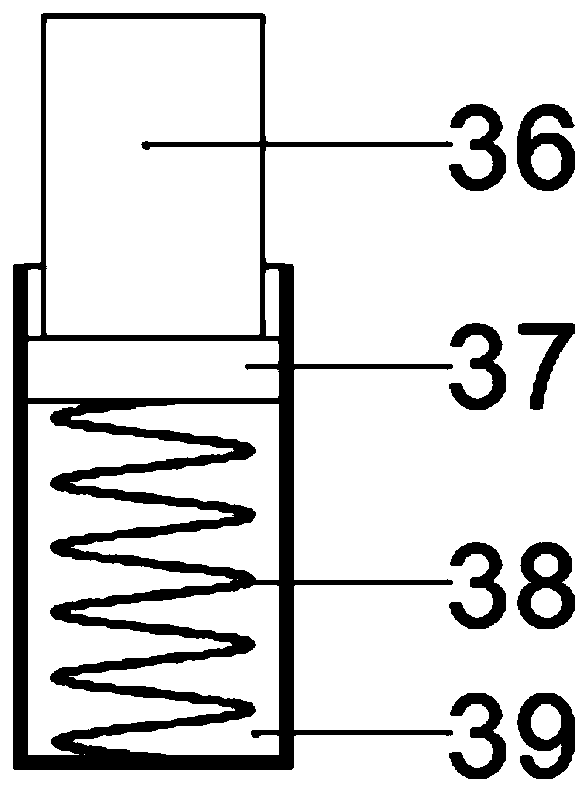

[0024] see Figure 1~4 , in an embodiment of the present invention, a grinding device for production and processing of stainless steel products, comprising a shock-absorbing base and a support base 26, the support base 26 is fixed on the shock-absorbing base, the inside of the support base 26 is a cavity structure, and the shock-absorbing The base includes a first board body 1 and a second board body 3, and a shock-absorbing foam board 2 is fixedly sandwiched between the first board body 1 and the second board body 3, and a plurality of shock-absorbing foam boards are evenly embedded on the shock-absorbing foam board 2. Shocking ball 40, the shock-absorbing ball 40 is a solid rubber ball, the first plate body 1 and the second plate body 3 are provided with a plurality of slots for clamping the shock-absorbing ball 40, and the support seat 26 is provided with a grinding unit , a clamping unit and a cooling and dedusting unit, wherein the clamping unit is located directly below ...

Embodiment 2

[0031] see Figure 5 The difference between this embodiment of the present invention and Embodiment 1 is that further, in order to facilitate the movement of the device, a plurality of moving wheels 41 are symmetrically arranged at the bottom of the shock-absorbing base, and the moving wheels 41 are self-locking rollers, each The moving wheels 41 are provided with brake assemblies, and the staff can easily and conveniently move the device through the moving wheels 41, which is simple and practical.

[0032] The working principle of the present invention is: when the present invention is in use, the stainless steel product is first clamped and fixed by the clamping unit so that the end face to be polished faces upward, and then the first servo motor 4 is started to make the grinding disc 15 and the stainless steel product to be polished surface contact, finally start the second servo motor 12 and the first water pump 27 for grinding, and the first water pump 27 sprays the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com