To-be-detected device replacing device for valve strings and using method thereof

A technology of devices and valve strings, which is applied in the field of replacement devices for devices to be inspected, can solve the problems of large volume of press-fit modules, high risk factors, and damage to optical cables, and achieve the effects of good versatility, good safety, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

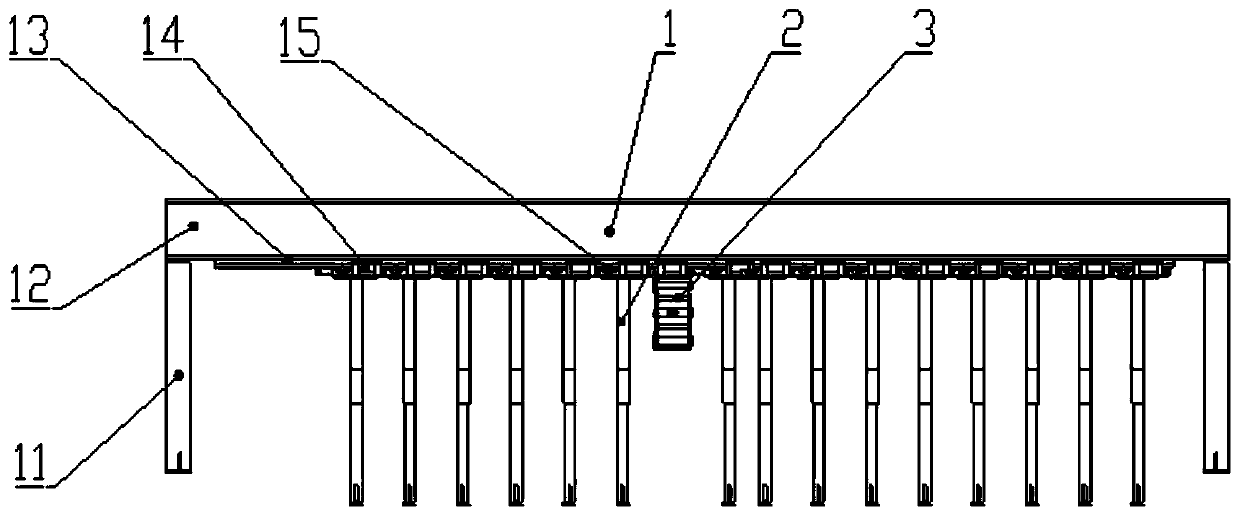

[0041] Such as Figure 1~4 As shown, a device to be tested for a valve string replacement device, which includes:

[0042] A support assembly 1, the support assembly 1 is suitable for being connected to the valve string 4;

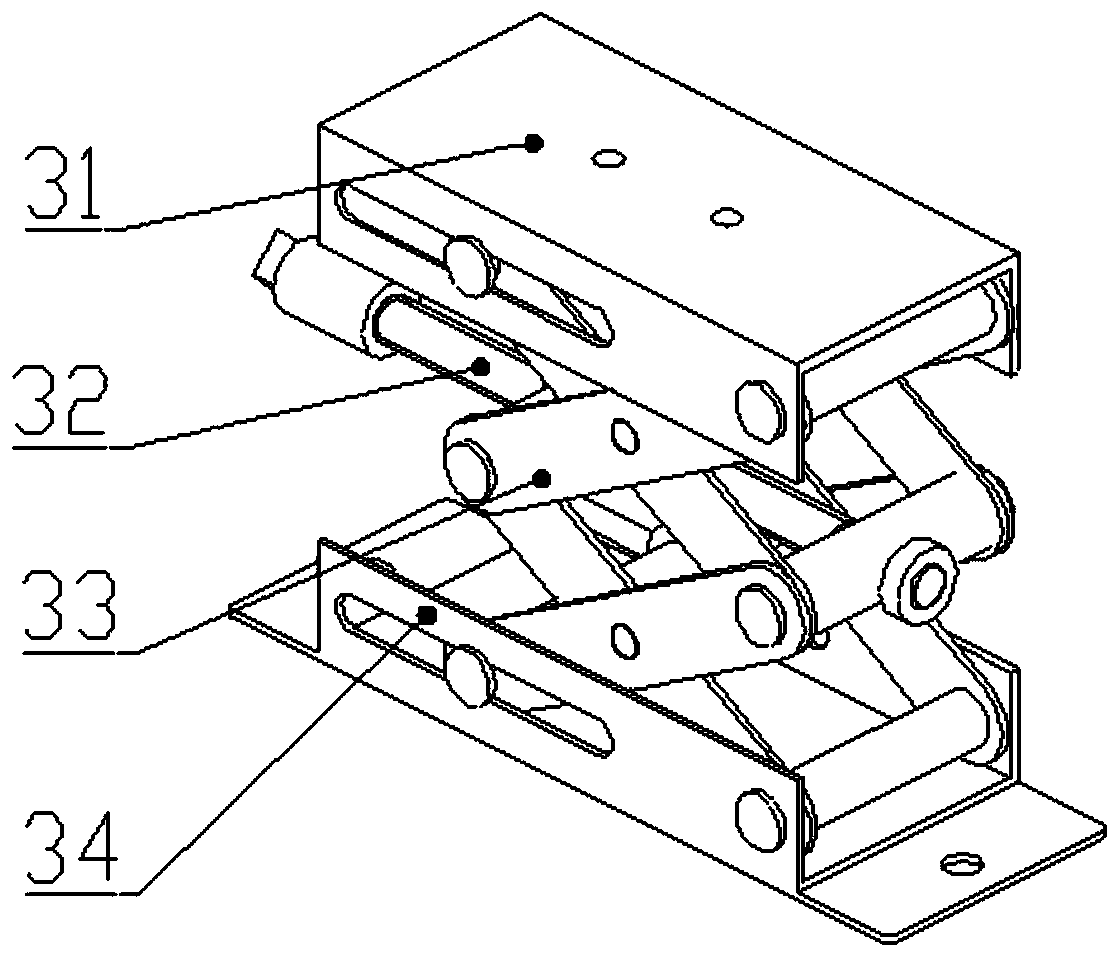

[0043] At least one fixing component 2, the fixing component 2 is connected to the support component 1, and the fixing component 2 is suitable for fixing at least part of the remaining non-testing devices except the testing device;

[0044] A lifting assembly 3, the lifting assembly 3 is connected to the support assembly 1, the lifting assembly 3 is suitable for connecting with the device to be inspected and driven to lift the device to be inspected.

[0045] In this embodiment, there are multiple fixing components 2, which are set correspondingly to the non-tested devices.

[0046] In this embodiment, both the device to be inspected and the device not to be inspected may refer to a heat sink.

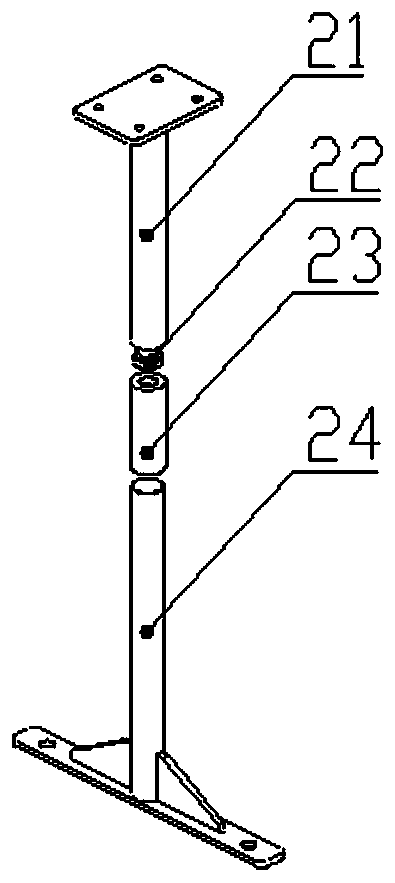

[0047] Specifically, such as figure 1 As shown, the suppo...

Embodiment 2

[0072] A method for using the device for replacing the device to be inspected for the valve string in Embodiment 1, the steps of the method include:

[0073] Install the support assembly 1 on the valve string 4;

[0074] The fixing component 2 is connected and pressed against the corresponding non-tested device;

[0075] The lifting component 3 is connected to the device to be inspected, and the lifting component 3 is operated to lift the device to be inspected.

[0076] The concrete steps of the using method of the present embodiment are:

[0077] The first step, preparation work: the valve string 4 is powered off, and the control and protection device is removed;

[0078] The second step is to install the support assembly 1: use bolts to fix the support assembly 1 on the upper surface of the front and rear press-fit plates of the valve string 4 through the through holes of the support legs 11, and the upper surfaces of the press-fit plates are processed with corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com