Composite joint with plate type rigidity adjusting structure

A compound joint and adjusting structure technology, which is applied in the direction of railway couplings, railway car body parts, traction devices, etc., can solve the problems of poor locomotive running stability, increase the stiffness of the coupler, lack of variable stiffness of the coupler, etc., and achieve slow down The effect of wear, low derailment coefficient and good dynamic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

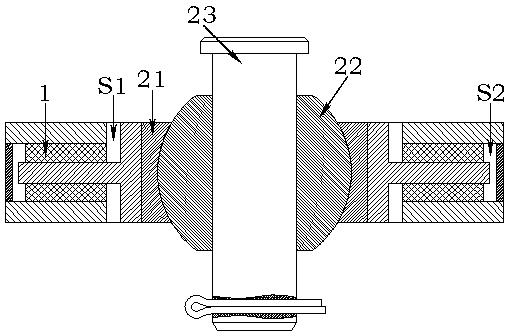

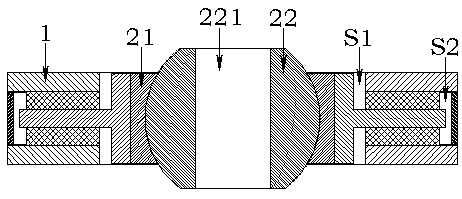

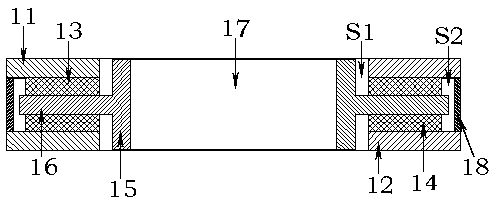

[0026] Such as figure 1 and image 3 As shown, the composite joint includes a rubber joint 1 and a metal joint, wherein the rubber joint 1 includes an end plate, a middle partition, a rubber body and an auxiliary ring 18 . And middle dividing plate comprises vertical dividing plate 15 and horizontal dividing plate 16, has the dividing plate through hole 17 that runs through vertical dividing plate 15 in the middle of vertical dividing plate 15, makes vertical dividing plate 15 be hollow circular tube shape. The transverse partition 16 is integrally formed on the outer side of the vertical partition 15, and the transverse partition 16 is in the shape of a hollow ring. When the middle partition is cut vertically, its section is two transverse and relatively distributed T-shaped sections.

[0027] An upper end plate 11 is arranged above the diaphragm 16, and an upper rubber body 13 is vulcanized between the diaphragm 16 and the upper end plate 11 to form a whole. A lower end p...

Embodiment 2

[0034] The difference from Embodiment 1 is that there is no auxiliary ring 18 in this embodiment, and when the intermediate partition moves in the radial direction relative to the end plates, the rubber body first deforms to provide linear stiffness. When the middle partition gradually moves to the end plate until the vertical partition 15 touches the end plate, the end plate will produce a damping force that prevents the middle partition from moving, and now the rubber joint 1 will become rigid. The cushioning performance of the composite joint in this embodiment in the radial direction will be worse than that of Example 1, but this embodiment can also be applied to working conditions where the vehicle does not require high cushioning performance but has high requirements for small-curvature turning of the vehicle .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com