Yarn storage tube for work station of textile machine and work station of textile machine

A yarn storage tube and textile machine technology, applied in the field of yarn storage tube, can solve problems such as the structural defect of the yarn monitor, and achieve the effect of high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

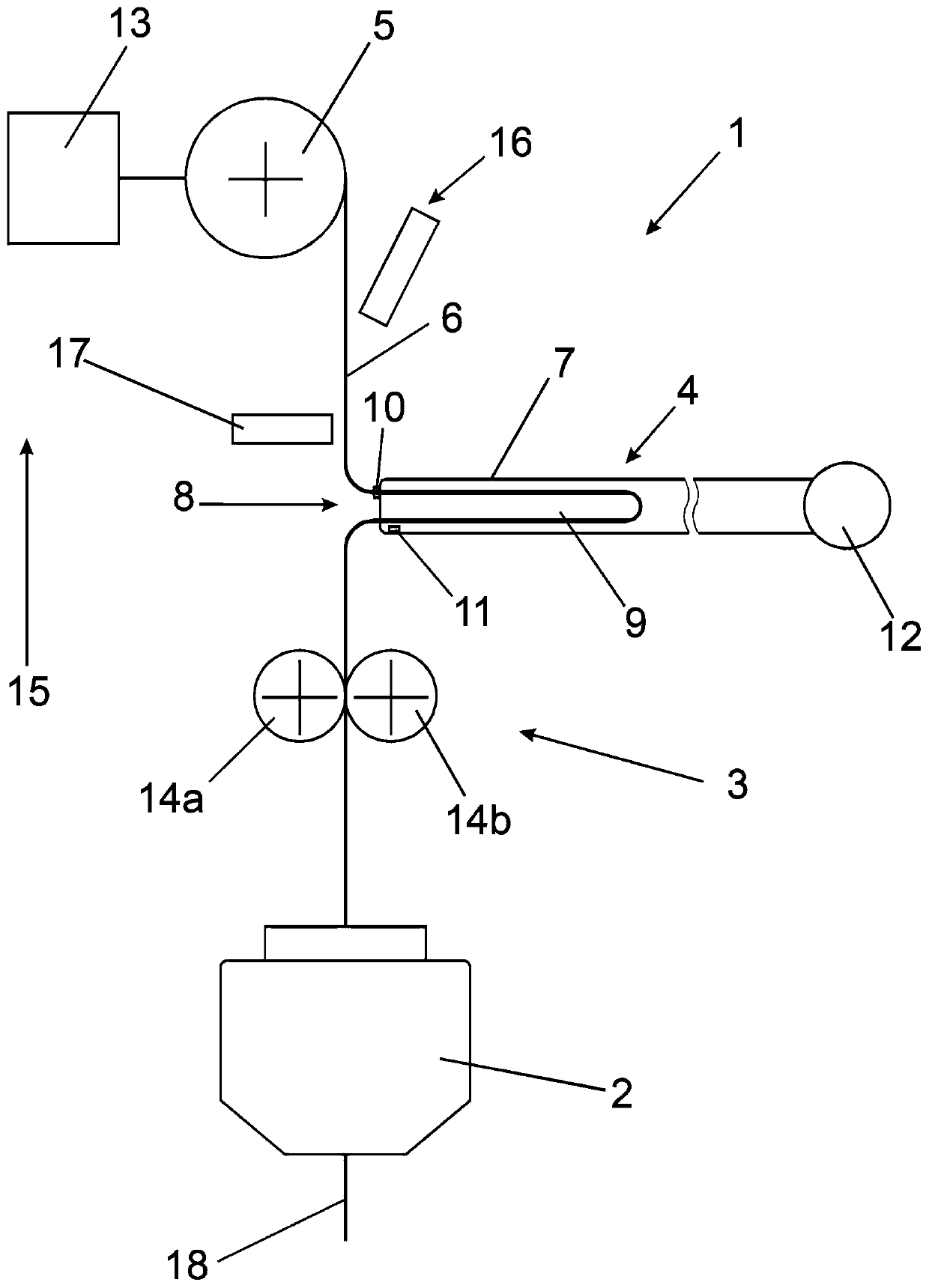

[0052] figure 1 A schematic diagram is shown of the station 1 with the yarn 6 extending from the spinning unit 2, for example an air spinning unit or a rotor spinning unit, to the yarn winding device 5 during the spinning process. The fiber slivers 18 supplied to the spinning unit 2 are drawn in the spinning unit 2 after passing through a drafting device not shown here in the case of an air spinning machine or an opening unit in the case of a rotor spinning machine. Twist.

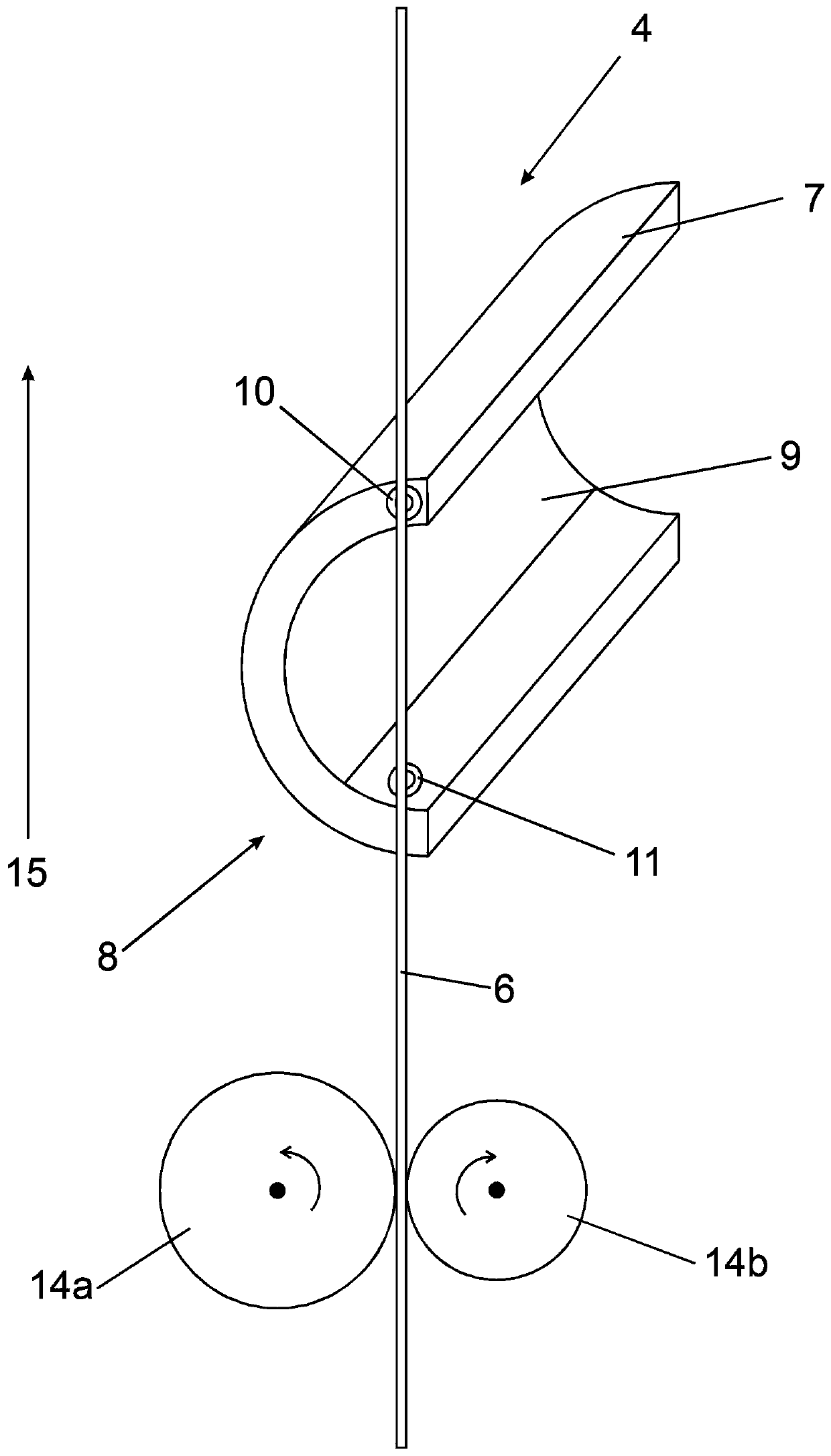

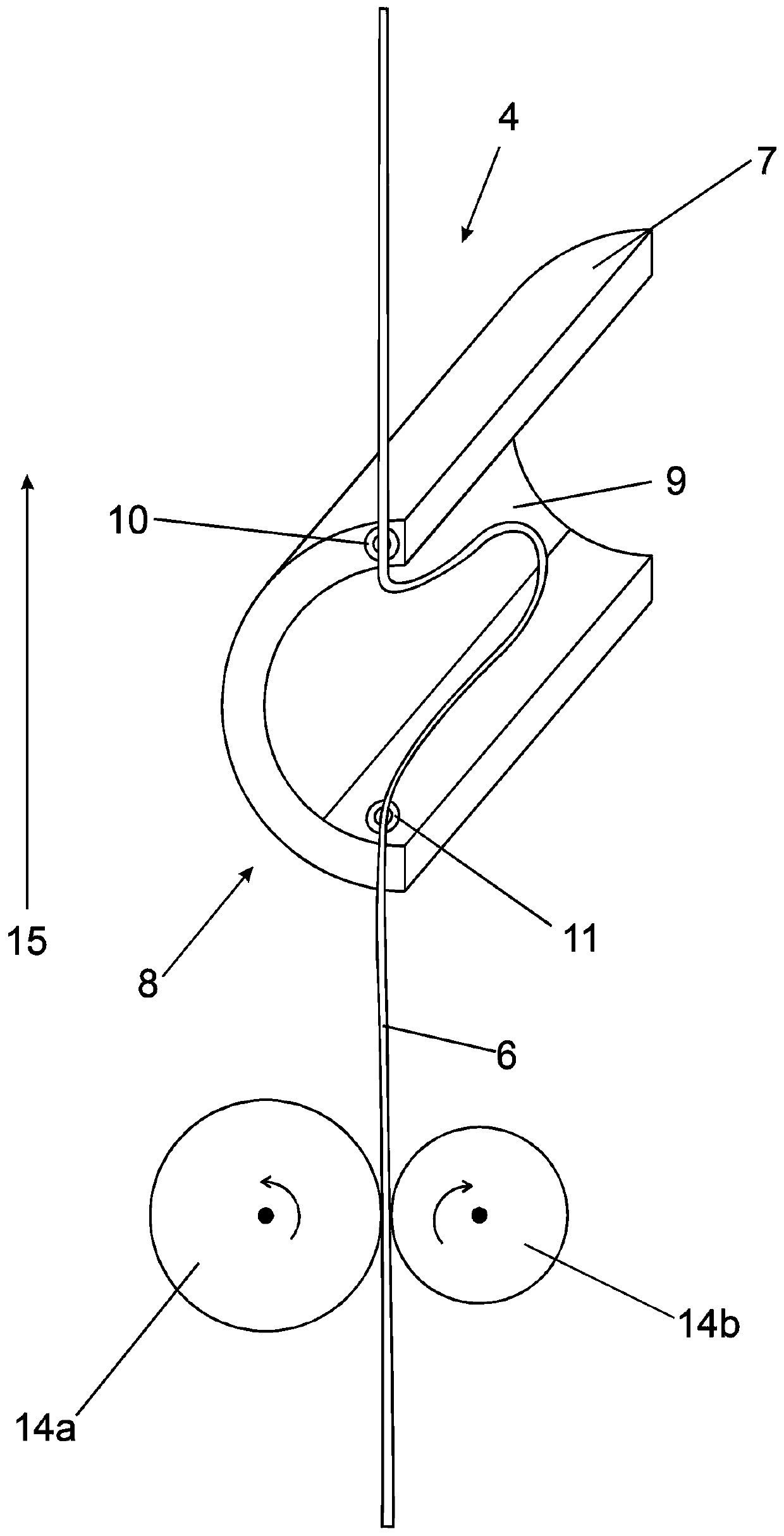

[0053] With regard to the direction of yarn movement 15, after the spinning unit 2 there is an unwinding device 3 which takes the yarn from the spinning unit 2 from the spinning unit by means of two unwinding rollers 14a, 14b forming a pair of unwinding rollers. The yarn unit 2 is withdrawn and fed to the yarn winding device 5 . Arranged after the unwinding device 3 is a yarn accumulator 4 with a yarn accumulator 7, on which a first yarn sensor 10 and a second yarn sensor 11 are integrated in the region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com