A Construction Method for Reinforced Bridgehead Subgrade of Expressway in Collapsible Loess Area

A technology for collapsible loess and highways, applied in soil protection, infrastructure engineering, roads, etc., can solve problems such as bridge head jumping, reduce stiffness difference, increase resilience modulus, and improve mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

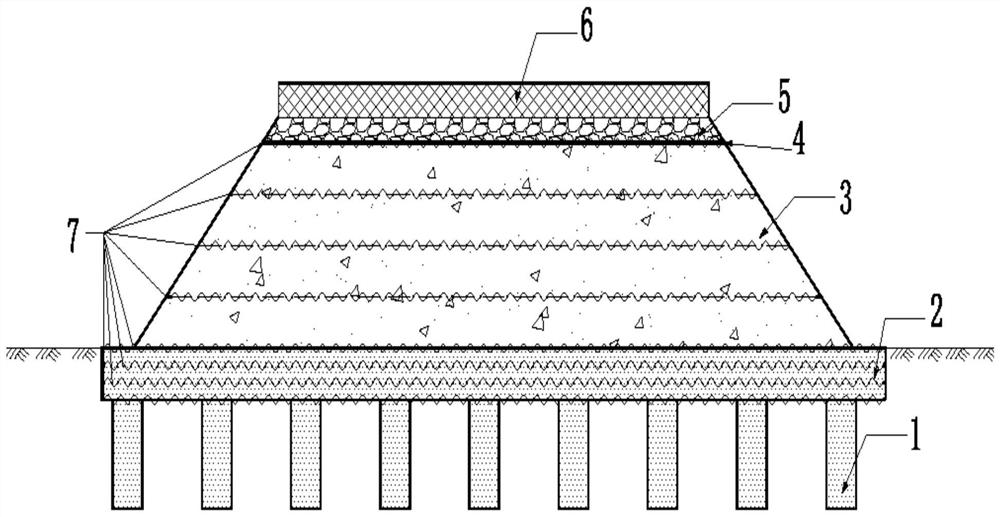

[0031] The construction method of the embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings. The specific construction method is as follows:

[0032] A reinforced bridgehead subgrade of expressway in collapsible loess area, from bottom to top, consists of sand-mixed lime soil pile composite foundation 1, reinforced sand-mixed lime soil cushion layer 2, reinforced sand-mixed lime soil backfill layer 3, anti-seepage geotechnical engineering Membrane 4, graded crushed stone cushion 5 and bridge head slab 6 are composed.

[0033] The lime soil in the sand-mixed lime soil pile composite foundation 1 is lime soil mixed with lime and loess at a volume ratio of 30:70 to form lime soil, and then lime soil and river sand are mixed at a mass ratio of 85:15 to form sand-mixed lime soil, and sand-mixed lime soil is used as the pile body material Fill the pile hole in layers, the compaction coefficient of the pile body mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com