Multi-anti-rotating coring device

A corer and anti-rotation technology, which is used in the extraction of undisturbed core devices and earthwork drilling, etc., can solve the problems of core component errors, large differences in accuracy, and estimated losses, reducing external interference and good anti-twist ability. , the effect of good anti-rotation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

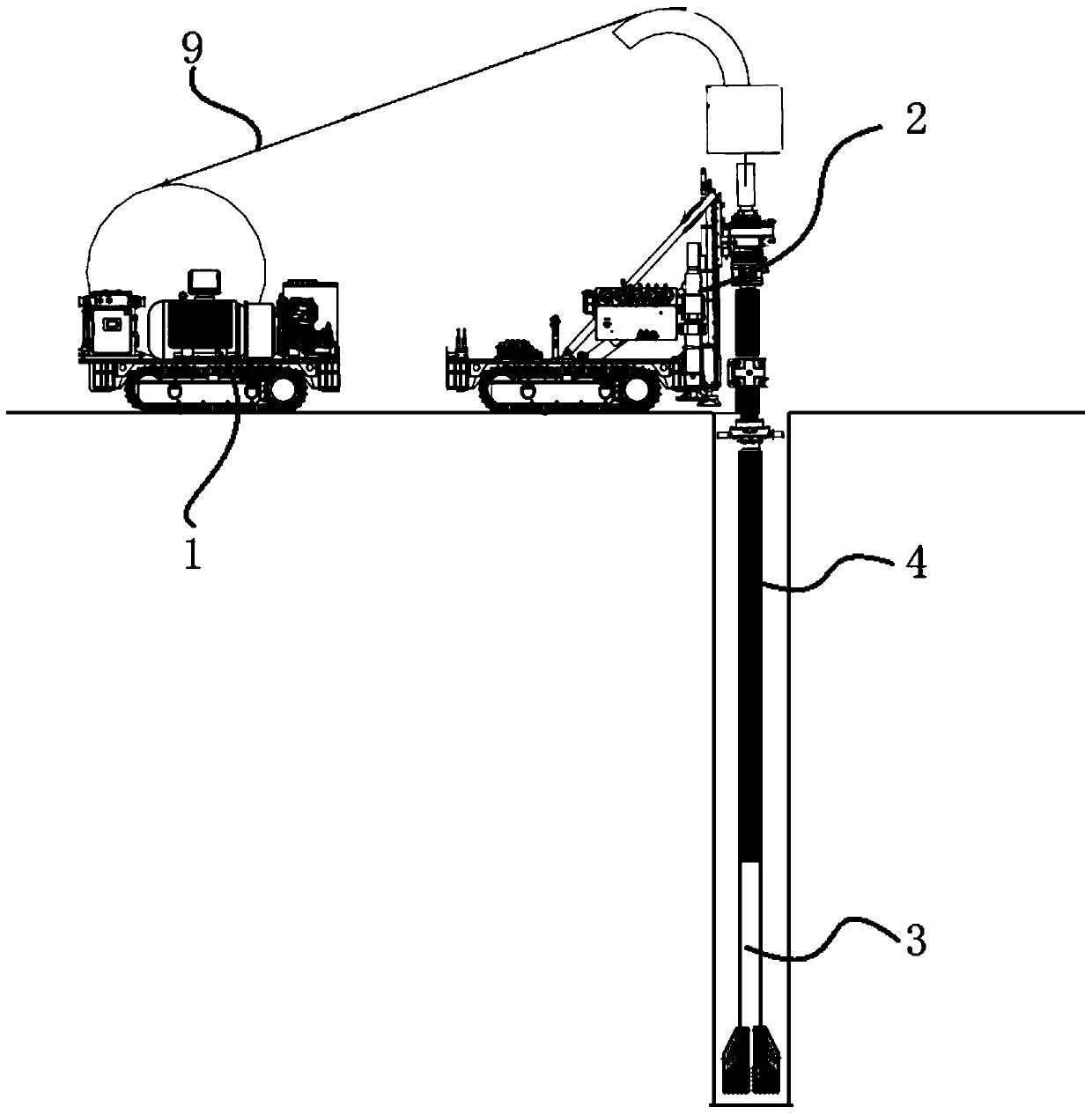

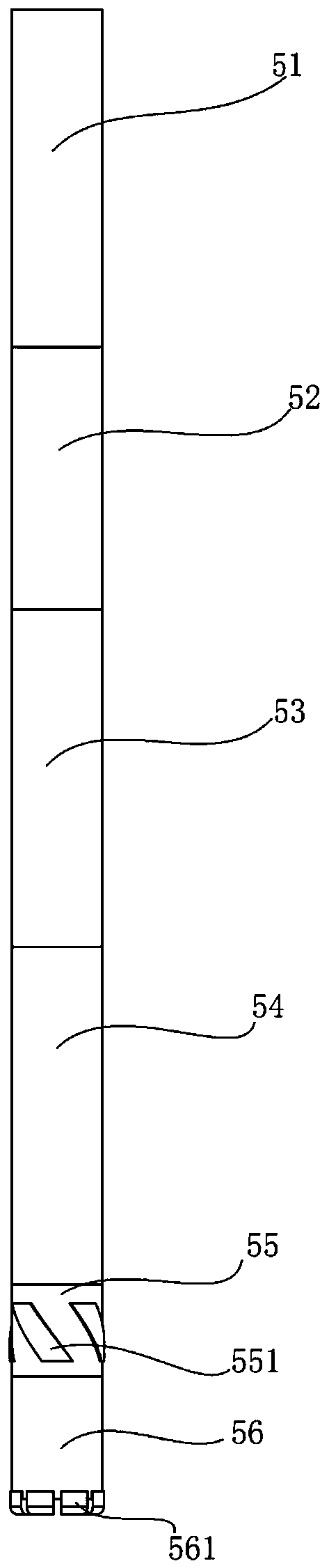

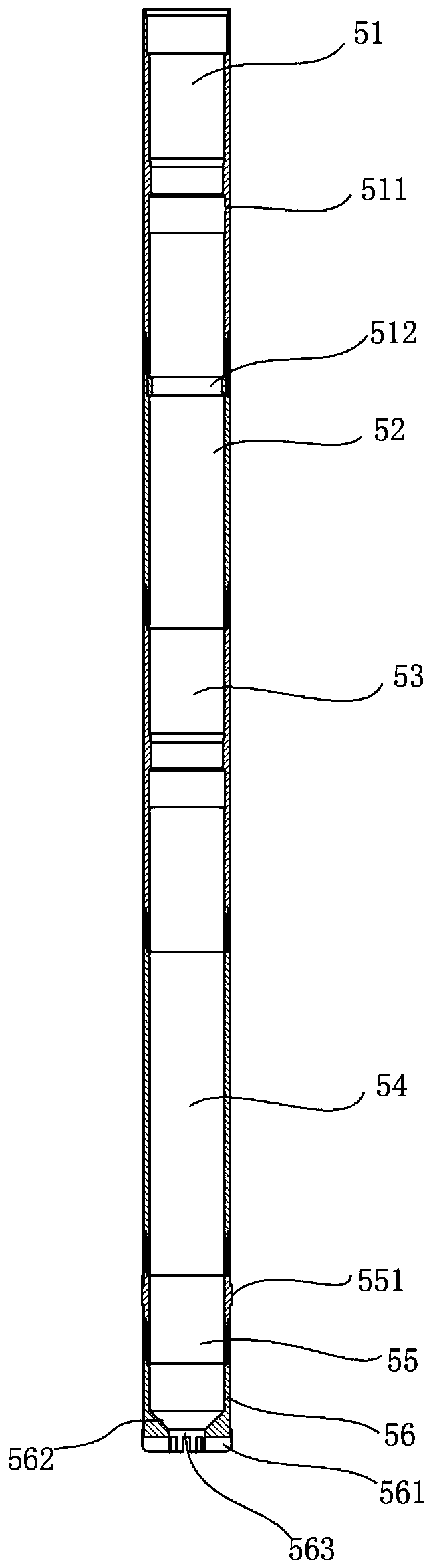

[0039] like Figure 1-9 As shown, the invention discloses a core remover with multiple anti-rotation functions,

[0040] The core remover 3 includes an outer tube assembly and an inner tube assembly. The inner tube assembly is lifted or lowered through a continuous conduit. The inner tube assembly is installed inside the outer tube assembly. The outer wall of the inner tube assembly and the outer tube assembly The inner pipe assembly includes an inner pipe assembly and a central assembly, the central assembly is installed in the inner pipe assembly, the outer wall of the central assembly slides with the inner wall of the inner pipe assembly, and the outer pipe assembly is connected to the drill pipe 4.

[0041] The outer pipe assembly includes a first pipe sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com