Petrochemical process pump

A petrochemical and process pump technology, applied in radial flow pumps, pumps, components of pumping devices for elastic fluids, etc., can solve the problem of not satisfying the user's pump flow and head, and reduce local head loss. , the fluid is smooth and smooth, the structure is compact and complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

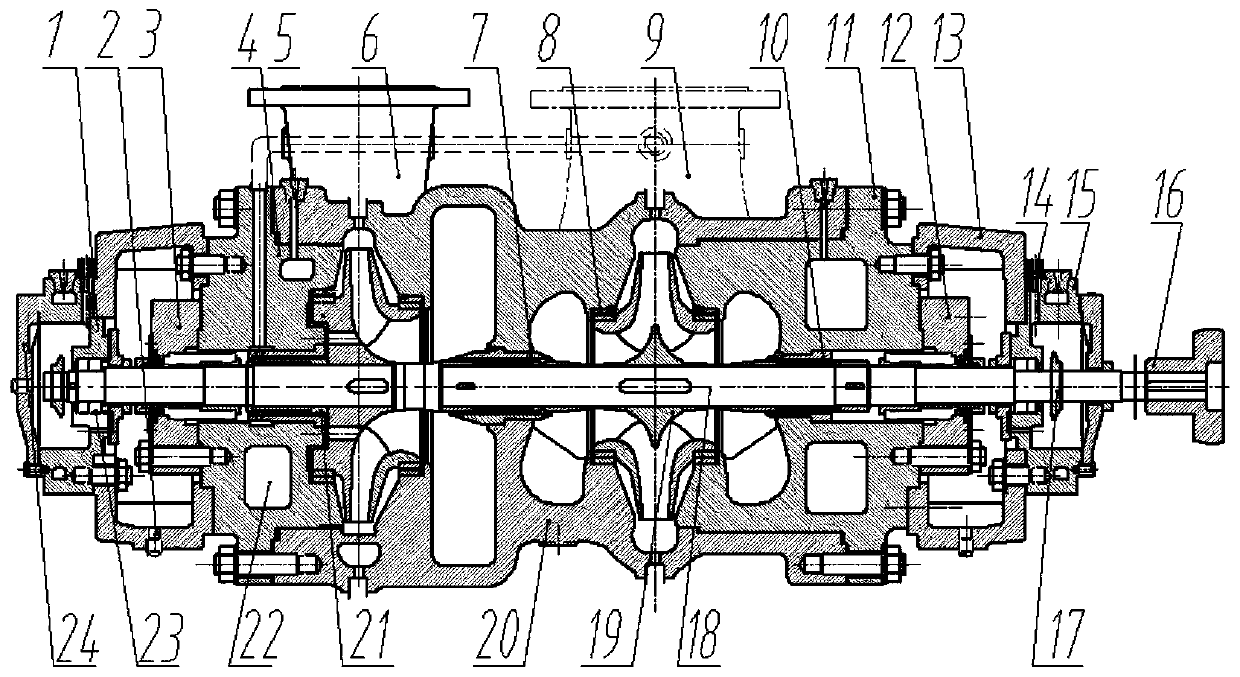

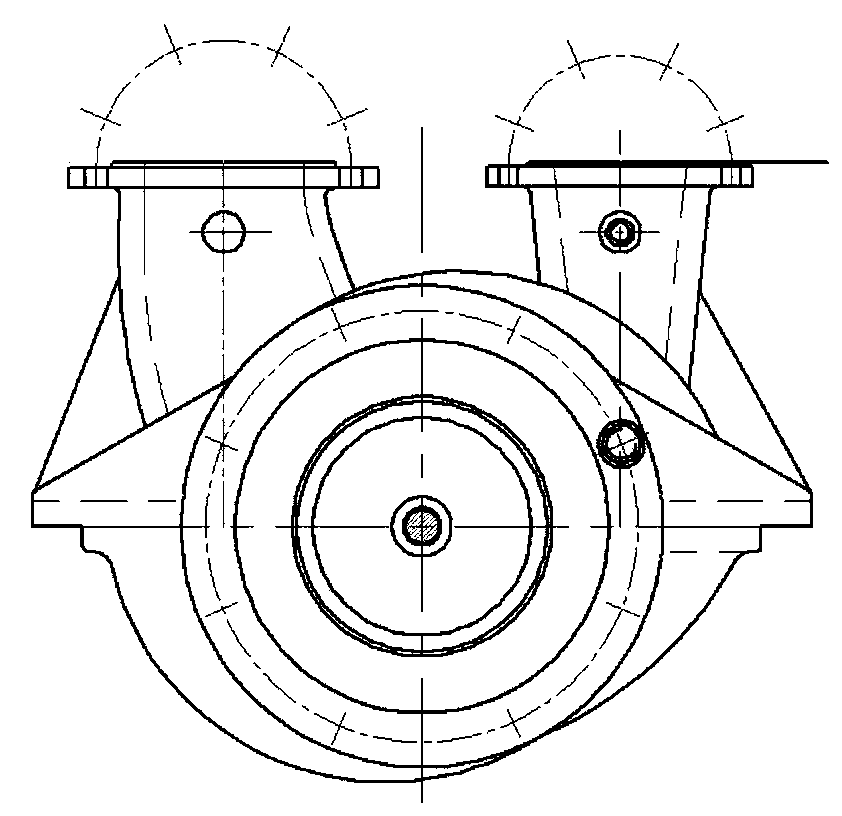

[0023] refer to figure 1 , the pump shaft is sequentially connected to the first stage impeller (19), interstage sleeve (7), pump body (20), pump body mouth ring (8), pump cover (4) (11), mechanical seal device from the center to both ends (3) (12), bearing parts, bearing (23), oil throwing ring (17), shaft end retaining ring (24) and shaft coupling (16) motor etc. The motor is directly driven, and the coaxiality of the connection between the motor shaft and the pump shaft needs to be checked regularly. The fluid flowing in through the semi-spiral suction chamber (9) passes through the first-stage double-suction impeller, and then flows into the lower pump through the transition channel. The first stage and the next stage are single-su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com