High-efficiency motor backward-tilting fan blade and manufacturing method thereof

A fan blade and backward tilting technology, which is applied in the field of high-efficiency motor backward tilting fan blades and its production, can solve the problems of affecting the production accuracy of fan blades, improving maintenance, and inability to disassemble, so as to reduce impact, overcome deformation, and not easily The effect of rebound phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

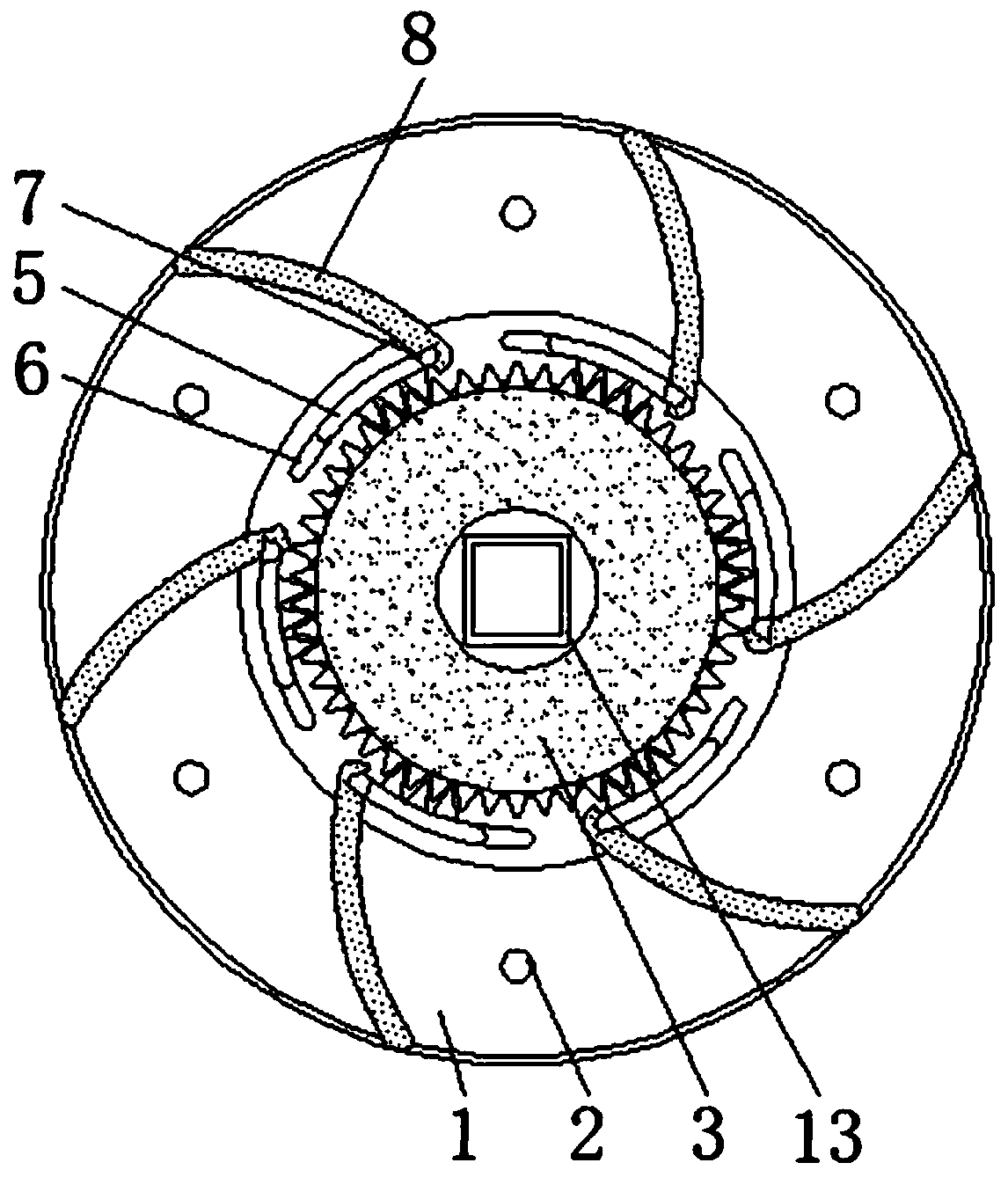

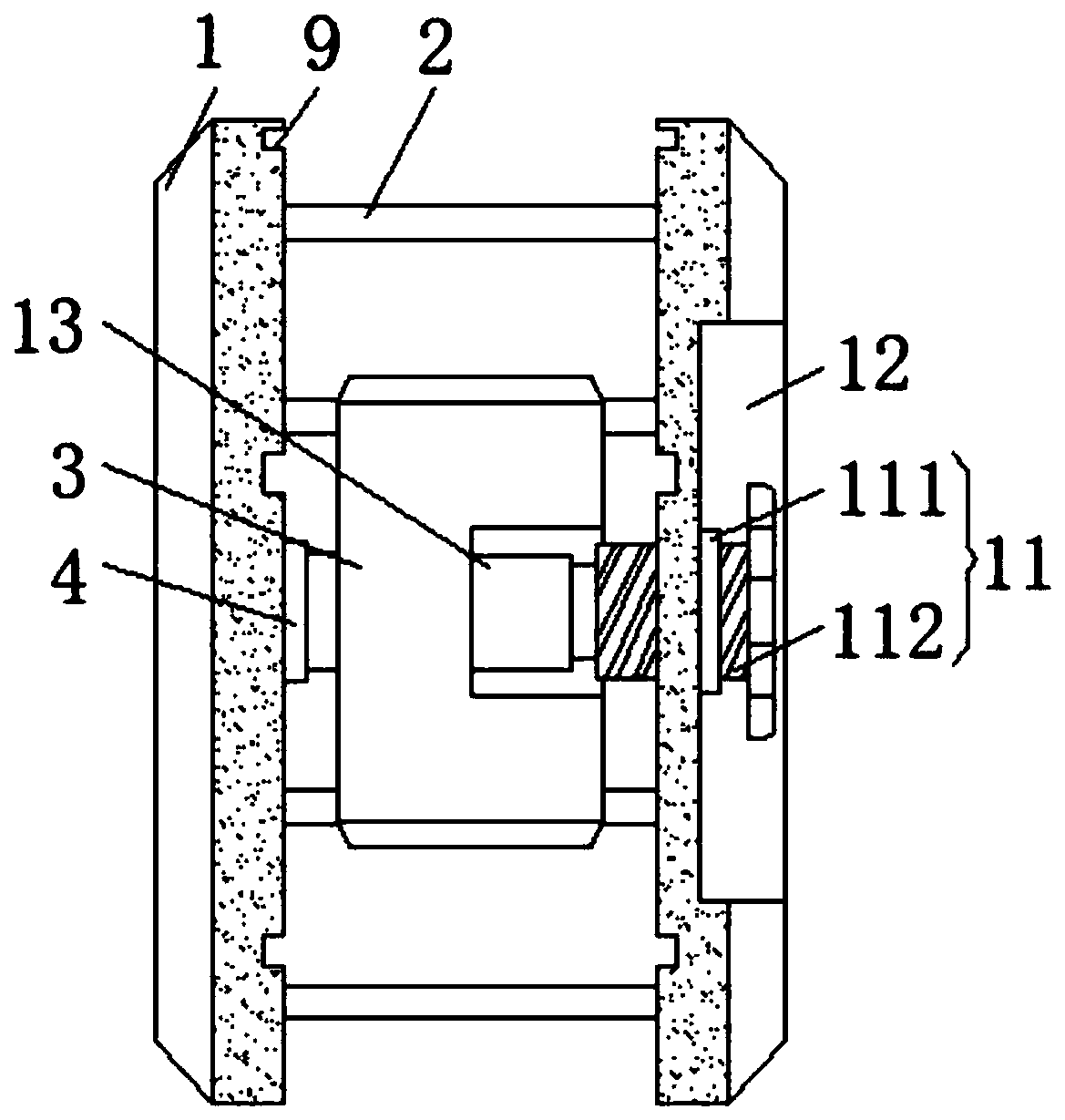

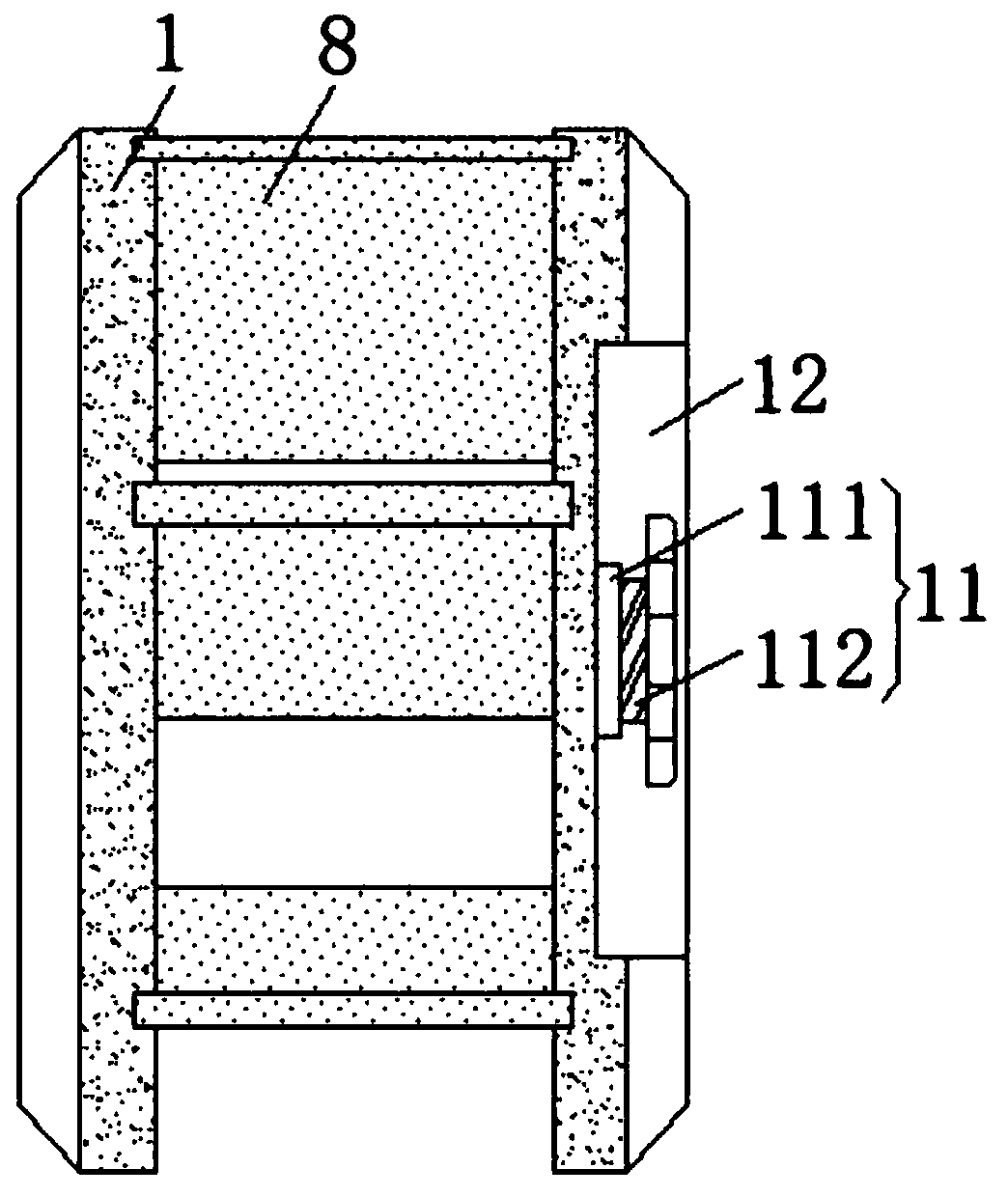

[0030] Such as Figure 1-4 As shown, the present invention provides a technical solution: a high-efficiency motor backward tilting fan blade and its manufacturing method, including two fan disks 1, the opposite surfaces of the two fan disks 1 are fixedly connected by six fixing rods 2, and the two fans The opposite surface of the disk 1 is provided with the same gear 3, the gear 3 meshes with the six gears 3, the tooth plate 5 is slidingly connected in two chute 6, and the gear 3 drives the tooth plate 5 to rotate due to the chute 6 It will not shake and is more stable. The two slide slots 6 are respectively set on the opposite surfaces of the two fan discs 1. One end of the tooth plate 5 is fixedly connected with a block 7, and the block 7 is snapped into the slot 10. By setting The block 7, the threaded rod 112 drives the telescopic rod 13 to sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com