Vacuum embossing machine for PU synthetic leather

A technology of vacuum embossing machine and synthetic leather, applied in textiles and papermaking, etc., can solve the problems of reducing product quality and poor embossing effect, and achieve the effect of improving product quality, good sealing performance, and not easy to texture rebound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

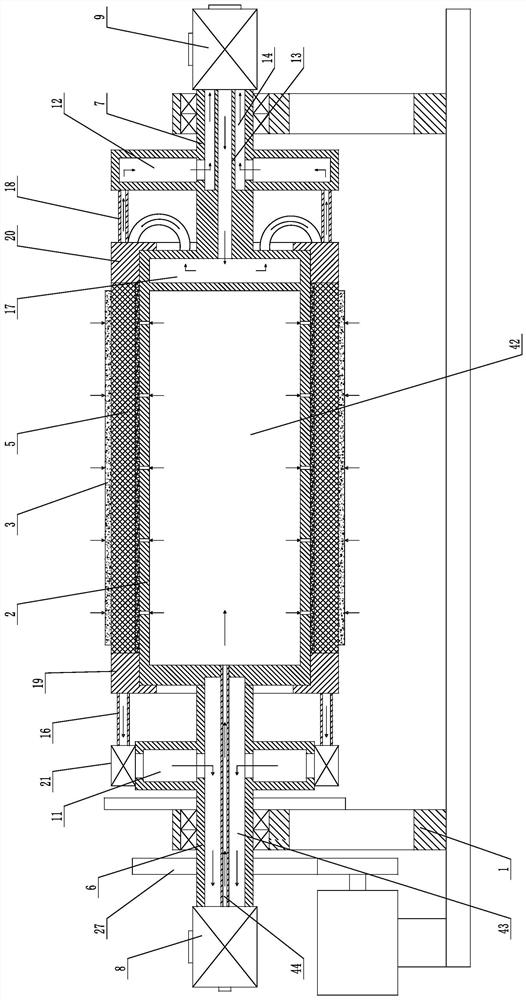

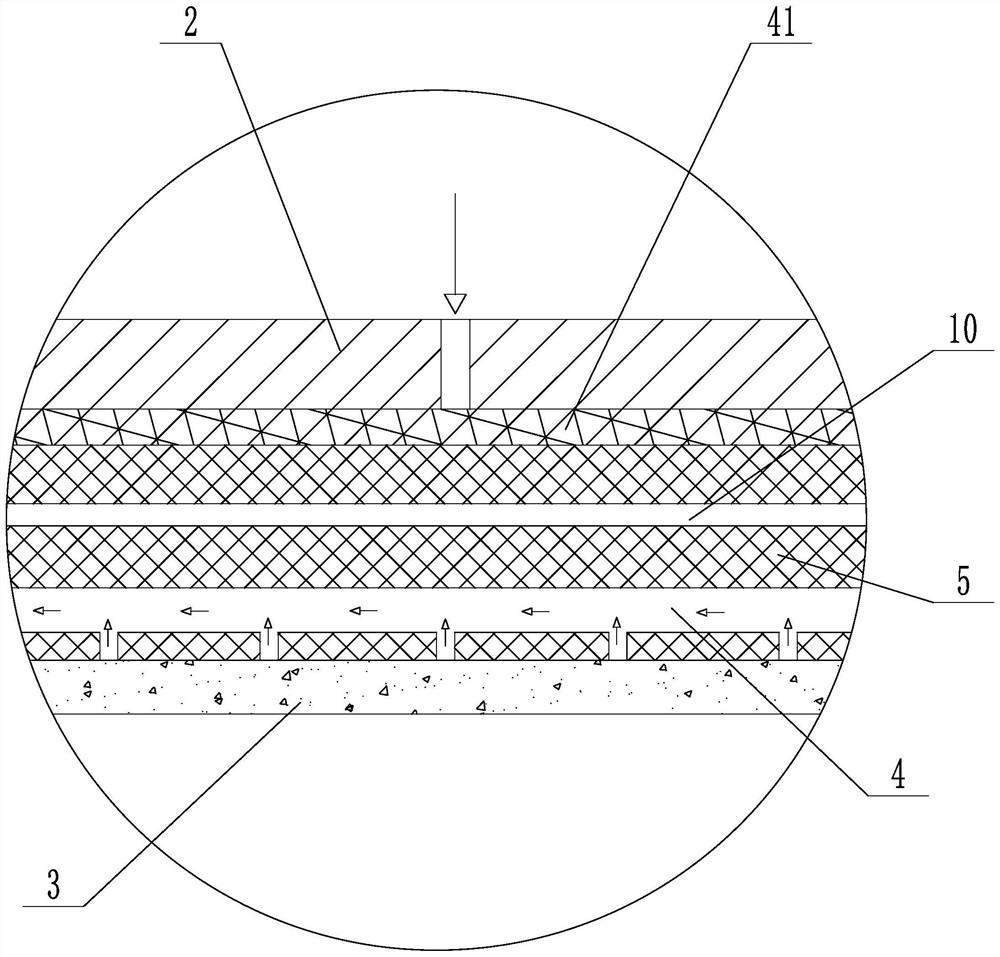

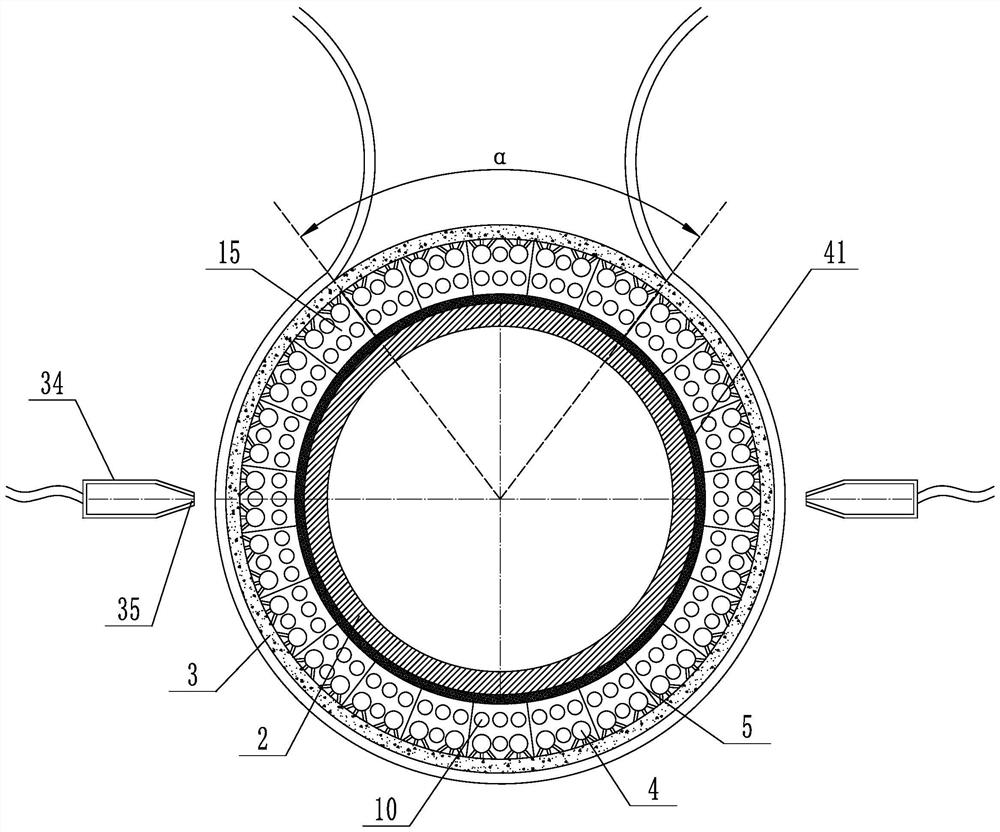

[0031] Embodiment 1: a kind of vacuum embossing machine of PU synthetic leather (see attached figure 1 to attach Figure 8 ), including frame 1, rotating roller 2 mounted on the frame, ventilating pattern cylinder 3 is arranged outside the roller, suction cylinder 5 is installed between the roller and ventilating pattern cylinder, and the suction cylinder is evenly distributed with A number of axially arranged airway holes 4, a row of suction holes are provided on the outer wall of the suction cylinder corresponding to each airway hole, the suction holes are connected with the airway holes, and the two ends of the roller are respectively provided with air rotating shafts. The core 6 and the water rotating shaft core 7, the air rotating mandrel is connected with the gas rotating joint 8, the water rotating mandrel is connected with the water rotating joint 9, the suction cylinder is provided with a water channel hole 10, and the water channel hole Both are connected with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com