Monocrystalline silicon wafer etching auxiliary, as well as preparation and using method thereof

A single crystal silicon wafer and texturing agent technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc. Solve the problems of large amount of alcohol or ethanol, etc., to achieve the effect of improving photoelectric conversion efficiency, excellent texturing effect, simple manufacturing and use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take the following process steps:

[0014] 1) Preparation of texturing aids: 20 ml of benzyl alcohol and 30 ml of triethanolamine were added to a 1000 ml volumetric flask, and then deionized water was added to obtain a 1000 ml solution.

[0015] 2) Prepare lye: dissolve 11 grams of sodium hydroxide in 989 grams of deionized water to obtain a 1.1% sodium hydroxide deionized aqueous solution by weight.

[0016] 3) Preparation of alkaline texturizing agent: the volume ratio of texturing auxiliary agent: lye is 1.5: 100, and the texturizing auxiliary agent is added to the lye to obtain the alkaline texturizing agent.

[0017] 4) Texturing: the monocrystalline silicon wafer for solar cells is immersed in the above alkaline texturing agent for surface texturing, the texturing temperature is 80°C, and the texturing time is 800s.

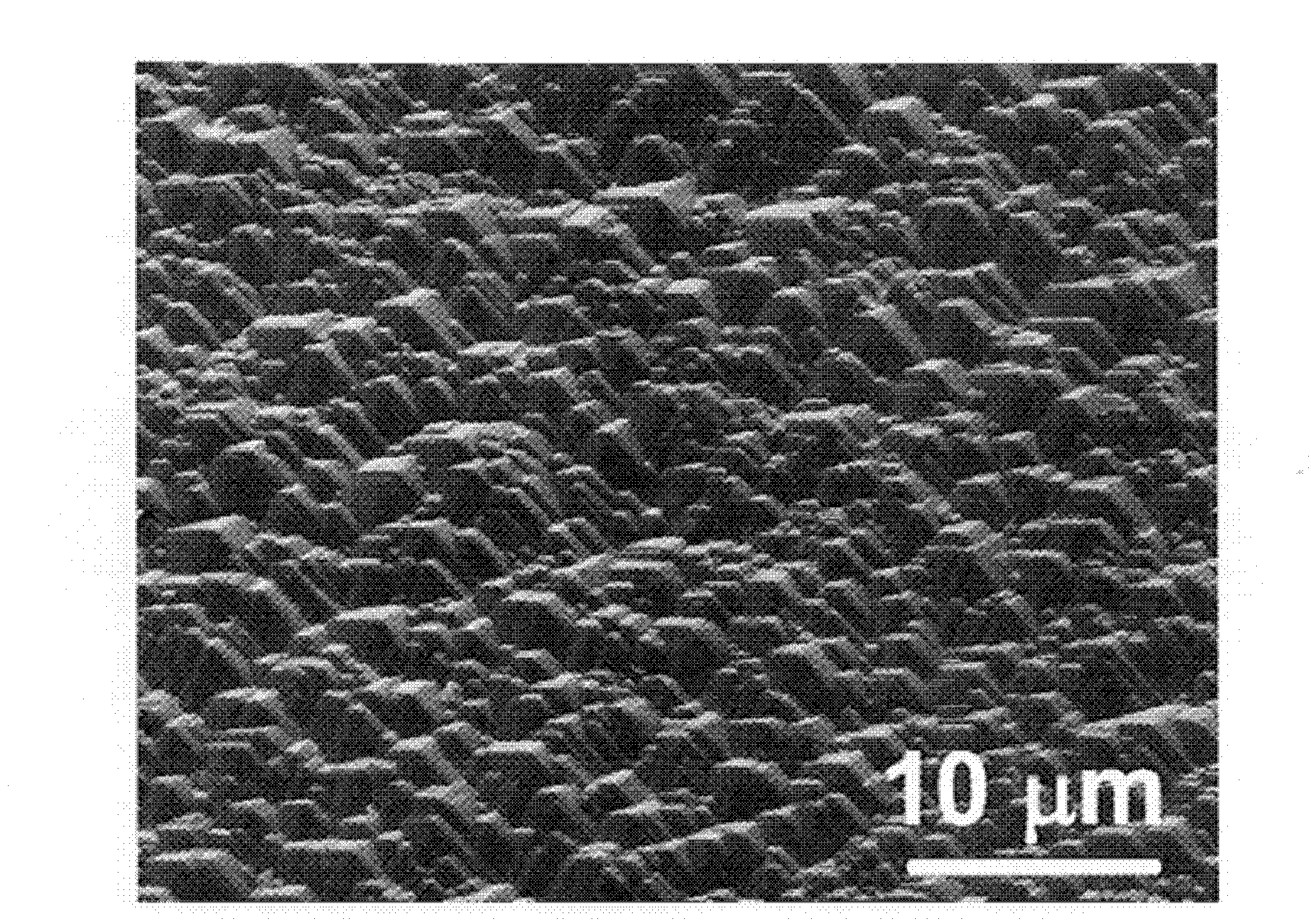

[0018] figure 1 A scanning electron microscope plane photo of the textured surface of the obtained silicon wafer is given. From the figure, it can...

Embodiment 2

[0020] 1) Preparation of texturing aids: 10 ml of benzyl alcohol and 40 ml of triethanolamine were added to a 1000 ml volumetric flask, and then deionized water was added to obtain a 1000 ml solution.

[0021] 2) Prepare lye: dissolve 8 grams of sodium hydroxide in 992 grams of deionized water to obtain a 0.8% sodium hydroxide deionized aqueous solution by weight.

[0022] 3) Preparation of alkaline texturizing agent: the volume ratio of texturizing auxiliary agent: lye solution is 0.5:100, and the texturizing auxiliary agent is added to the alkali solution to obtain the alkaline texturizing agent.

[0023] 4) Texturing: the monocrystalline silicon wafer for solar cells is immersed in the above-mentioned alkaline texturing agent for surface texturing, the texturing temperature is 85°C, and the texturing time is 720s.

[0024] In addition, no significant volatilization of components in the texturizing agent was observed in Example 1 and Example 2 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com