Washout-resistant sealing structure of regulating valve

A sealing structure and erosion-resistant technology, which is applied in the direction of the valve shell structure, lift valve, sliding valve, etc., can solve the problems of media erosion on the sealing surface of the valve core, reduce erosion and wear, reduce direct erosion, reduce Effect of Frequency of Repair or Replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

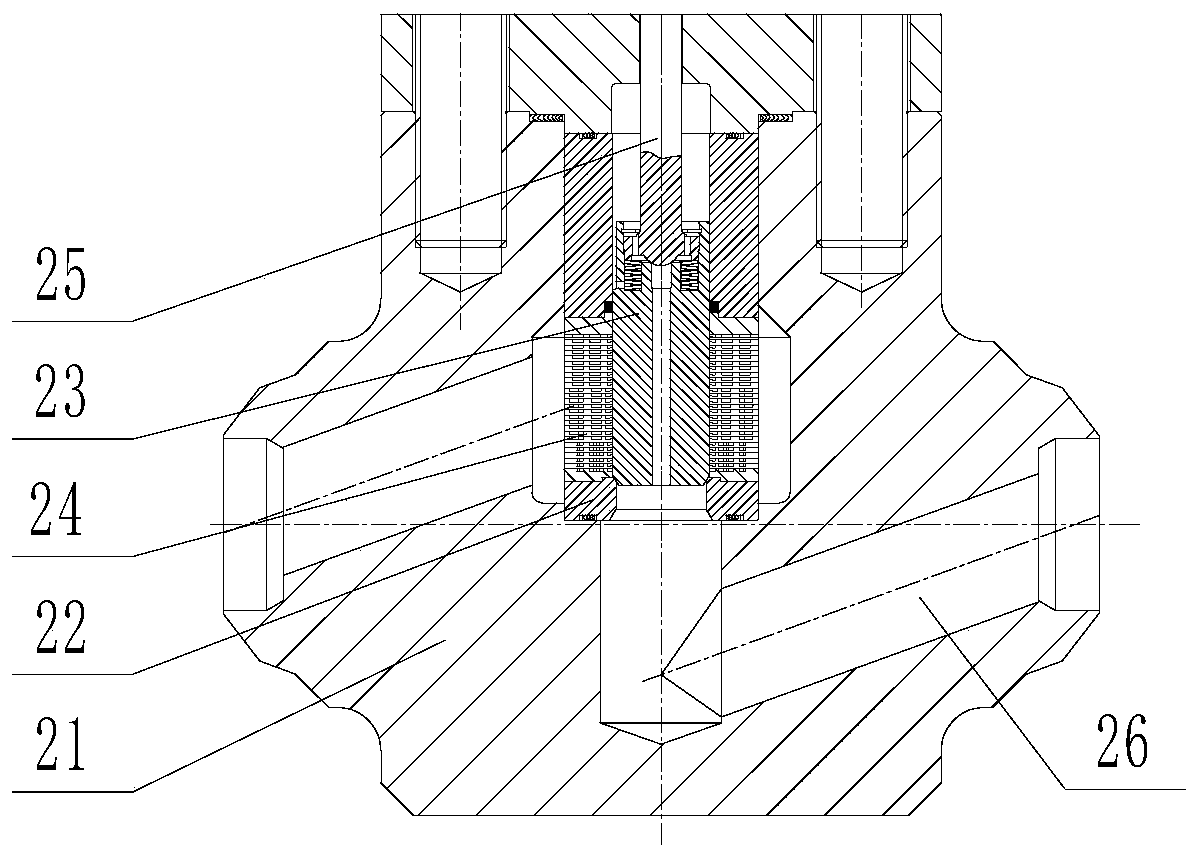

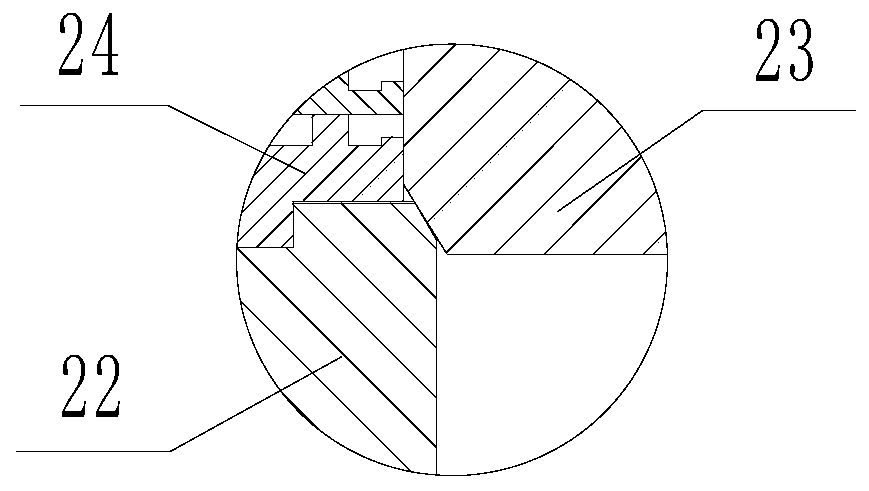

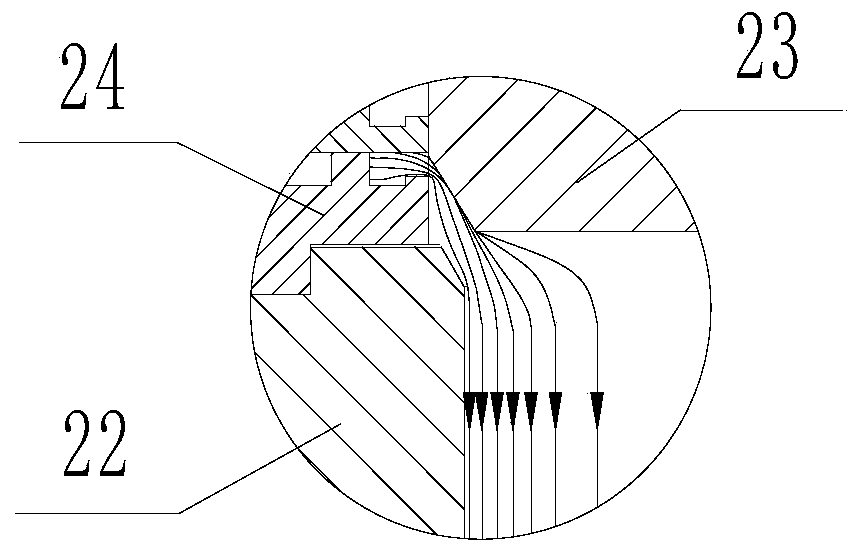

[0018] Such as Figure 4 and Figure 5 As shown, an erosion-resistant sealing structure of a regulating valve of the present invention includes a valve body 1, a valve seat 2, a valve core 3, and a sleeve 4 cooperating with the valve core 3. The inside of the valve body 1 is processed with a flow channel for the medium to pass through. , the flow path includes an inflow section 1-1, a buffer section 1-2, a valve cavity section 1-3 and an outflow section 1-4, and the cross-sectional area of the buffer section 1-2 is larger than the inflow section 1-1, the valve cavity section 1- 3. The cross-sectional area of the outflow section 1-4, the valve seat 2 is installed at the outlet of the valve cavity section 1-3, the sleeve 4 is installed in the buffer section 1-2, and the cross-sectional area of the buffer section 1-2 is larger...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap