Spiral rotor modeling method based on virtual generating machining

A modeling method and rotor technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problems of product quality, hidden dangers, complex analytical equations, etc., to meet the requirements of sealing and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

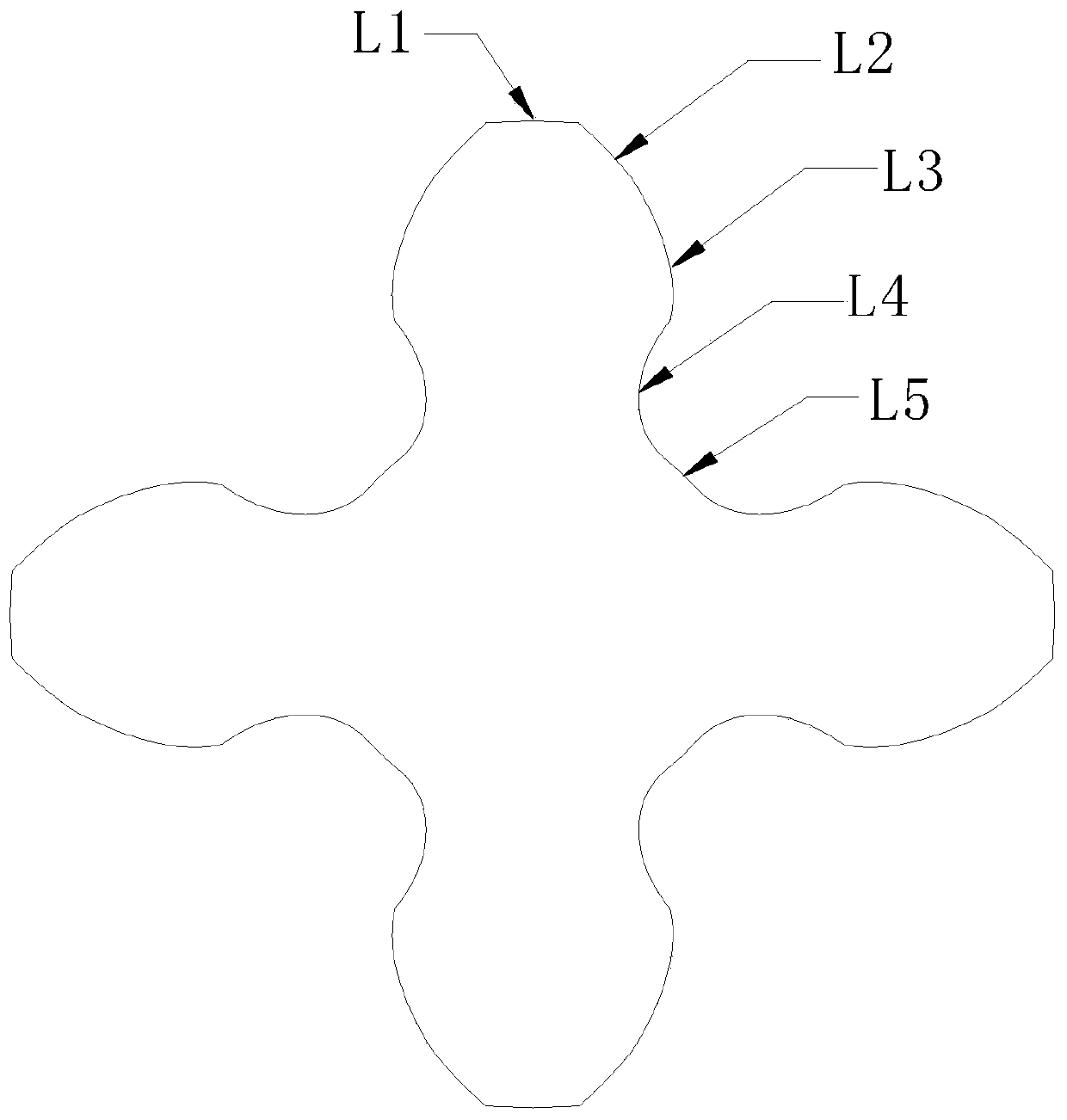

[0050] A helical rotor modeling method based on virtual fan-forming machining. Before modeling, it is necessary to determine the end surface profile of the helical rotor, such as figure 1 As shown, the compound tooth shape of the end face of the helical rotor includes the addendum arc segment L1, the transition curve II segment L2, the involute segment L3, the transition curve I segment L4, and the dedendum arc segment L5.

[0051] The modeling method of the helical rotor includes the following steps:

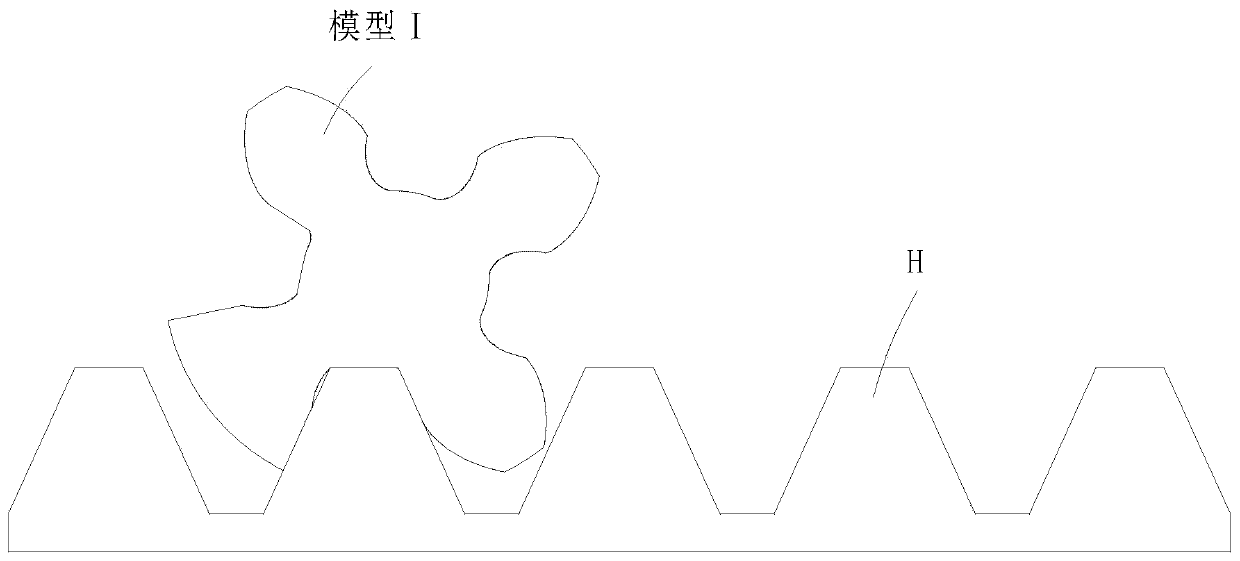

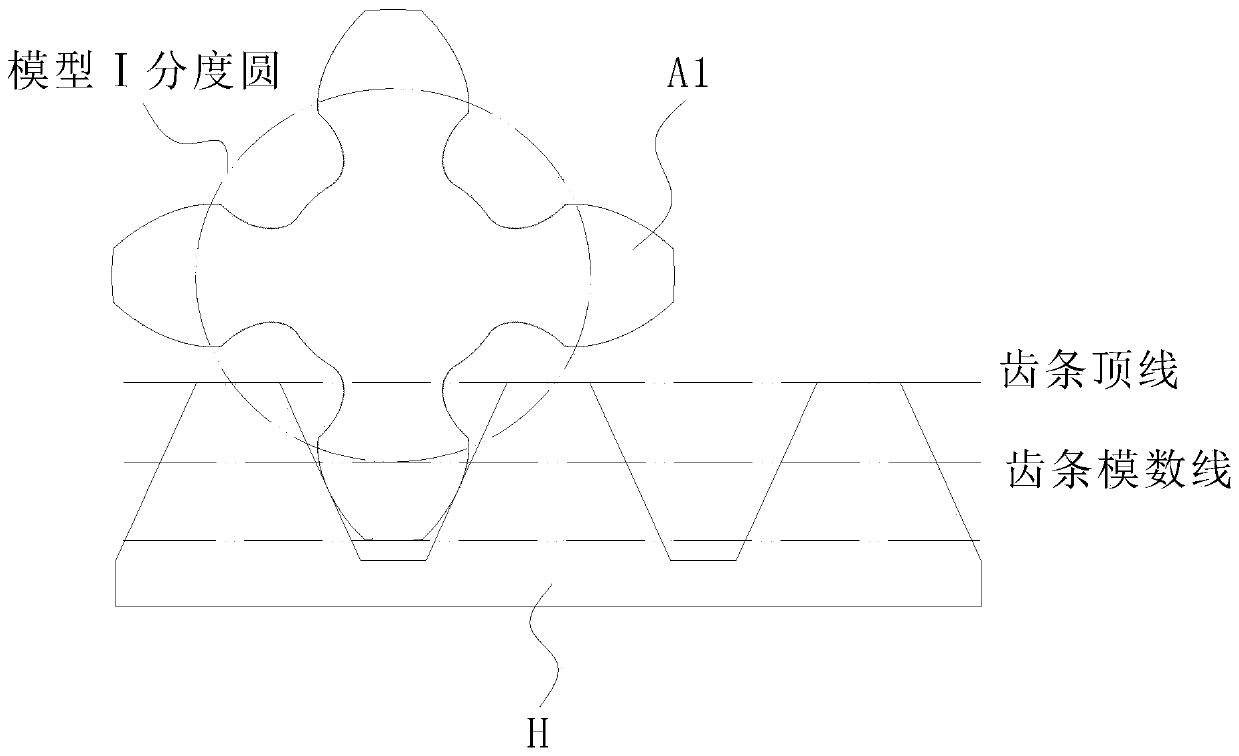

[0052] Step 1, such as figure 2As shown in Fig. 1, a suitable rack-shaped tool H is constructed by two-dimensional software, and the circular rotor blank model Ⅰ is processed by using the rack-shaped tool H to simulate the formation process of the tooth surface opening line, and the preliminary rotor end face A1 is obtained;

[0053] In this embodiment, the two-dimensional software is a computer-aided drawing program AutoCAD and an auxiliary assignment program developed by Au...

Embodiment 2

[0097] The difference between this embodiment and embodiment 1 is that, as Figure 12 As shown, in order to visually verify the correctness of the meshing of the modified rotor end face A4 profile model obtained by the above software, and the correctness of the modeling method of the end face profile of the helical rotor obtained through the above theoretical analysis and the correctness of the programming software running results, after the fourth step , using the above modified rotor end face A4 as the verification rotor tool O3, the circular rotor blank model IV is virtualized and processed, and the tooth surface opening line formation process is simulated to obtain the calibrated rotor end face A5, and the corrected rotor end face A4 and the calibrated rotor end face A5 are Perform coincidence comparison, verify the shape of the contour curves of the two, and go to step five after verifying that they are consistent.

[0098] After inspection, it is found that the contour c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com