A threaded hole structure that can accurately measure the state of threaded connections in real time

A threaded connection and precision measurement technology, which is applied in the direction of connecting components, measuring devices, threaded fasteners, etc., can solve problems that are difficult to real-time, and achieve reliable measurement results, convenient inspection and maintenance, and self-monitoring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

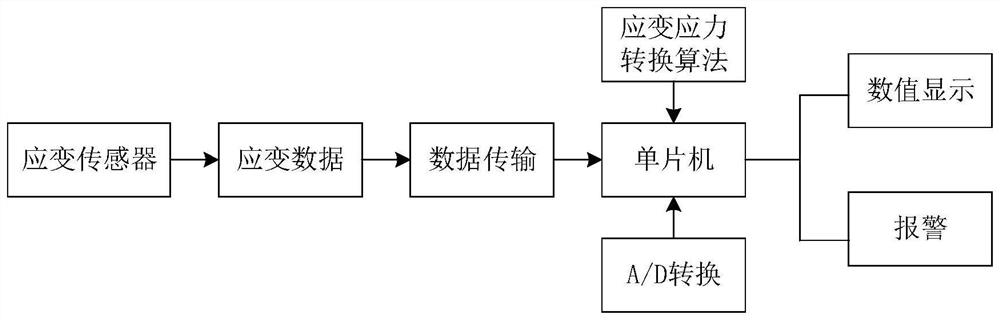

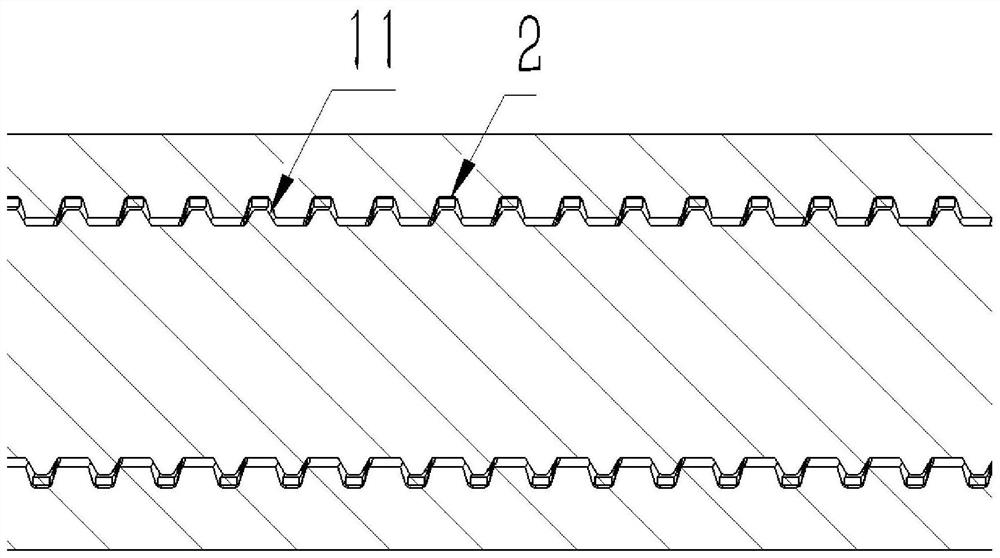

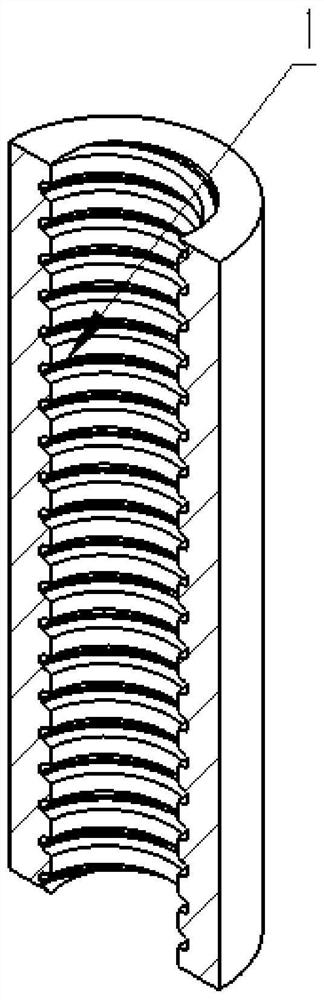

[0034] Such as Figure 1-6 As shown, a threaded hole structure capable of accurately measuring the threaded connection state in real time has the functions of connecting and measuring strain stress, and includes a threaded hole structure 1, a strain measurement module, a data transmission module and a single-chip microcomputer module. The strain measurement module is tight Attached to the inner wall of the threaded space 11 of the threaded hole structure 1, the strain measurement module is electrically connected to the data transmission module, and the data transmission module is electrically connected to the single-chip microcomputer module;

[0035] The threaded hole structure increases the diameter of the root circle on the basis of the corresponding standard threaded hole, so that the threaded major diameter of the threaded hole structure is larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com