A fuel assembly for a supercritical water-cooled reactor

A technology for fuel assemblies and water-cooled reactors, which is applied in the directions of reactor fuel elements, fuel elements, fuel element assembly, etc., can solve the problem that the cross-shaped control rod drop-rod fuel assembly cannot meet the small deformation of the fuel assembly at the same time, and achieve enhanced neutron moderation. High capacity, high structural stability, and the effect of improving neutron economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

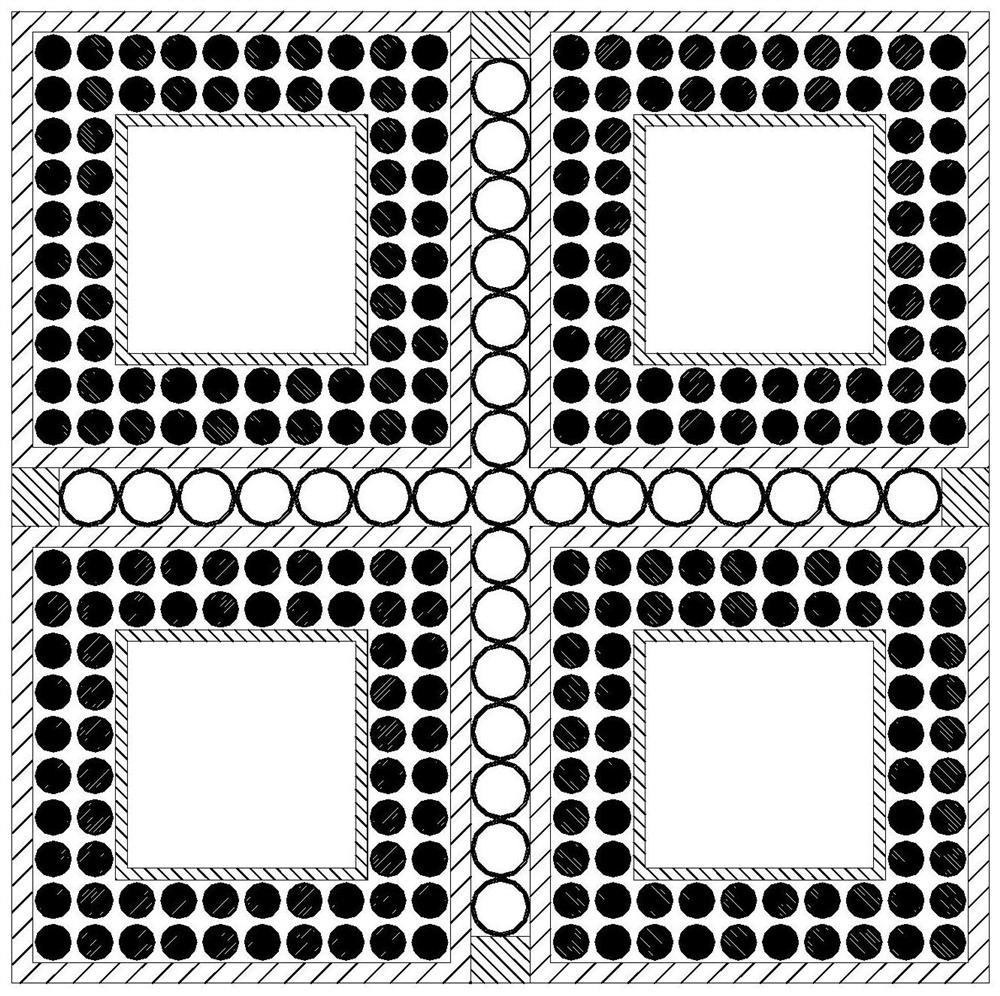

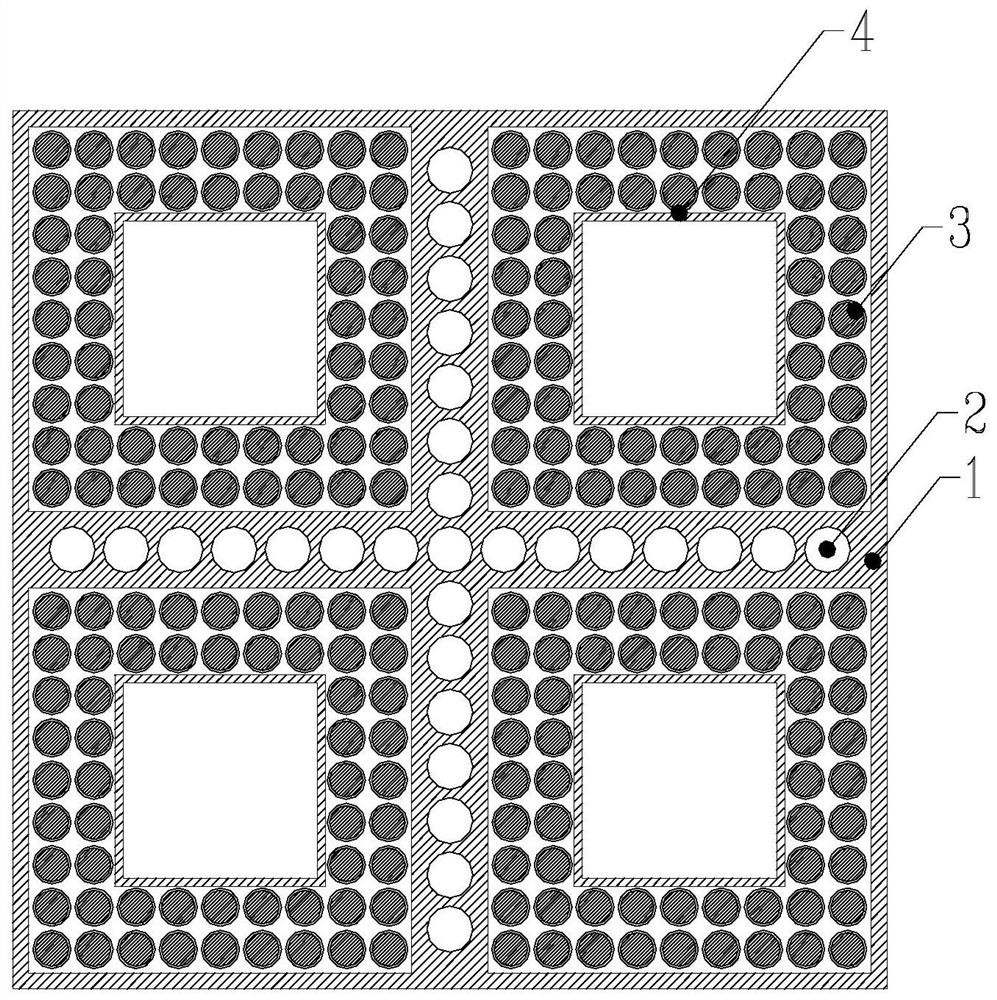

[0030] A fuel assembly with interpolated rod type control rods, such as figure 2 As shown, it includes four sub-assemblies arranged in a 2×2 manner, and a cross-shaped area is formed between the four sub-assemblies. The improvement of this embodiment lies in that a cross frame with a guide hole 2 at the center of the four sub-assemblies is used instead of figure 1 The guide tube in the control rod constitutes the insertion channel of the cross-shaped control rod, and the squeezing action of the control rod and the guide hole 2 can realize the safe drop of the cross-shaped control rod assembly; Improve the structural stability and deformation resistance of fuel assemblies.

Embodiment 2

[0032] A fuel assembly with inserted bundle rod-type control rods, on the basis of Embodiment 1, this embodiment optimizes the structure of the guide hole 2: the cross section of the guide hole 2 is circular or square, and the lower section has a ratio of aperture The aperture of the upper section is small.

[0033] In this embodiment, the hydraulic buffering effect of the guide hole 2 and the control rod is further increased by the water squeezing effect of the reduced aperture, and the impact force on the fuel assembly caused by the falling rod of the control rod assembly is reduced.

Embodiment 3

[0035] In a fuel assembly with inserted bundle rod type control rods, on the basis of any of the above embodiments, water rod boxes 4 are also provided, and the water rod boxes 4 are evenly distributed in the assembly box 1 . In this embodiment, by arranging the water rod boxes 4 evenly, the neutron moderation capability of the core is enhanced, the problem of insufficient neutron moderation in the supercritical water-cooled reactor is solved, and sufficient and uniform moderation of the fuel rods 3 is achieved. .

[0036] Preferably, each subassembly includes a water rod box 4 and several fuel rods 3 located between the water rod box 4 and the assembly box 1; a moderator channel is formed in the water rod box 4, and the water rod box 4 A coolant passage is formed between it and the component box 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com