Thin-film actuated reflection mirror having increased tilting angle

A thin-film mirror and mirror technology, which is applied in the field of optical projection systems, can solve the problems of the limited inclination angle of the thin-film actuated mirror 100 and the reduction of the overall optical efficiency of the thin-film actuated mirror.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

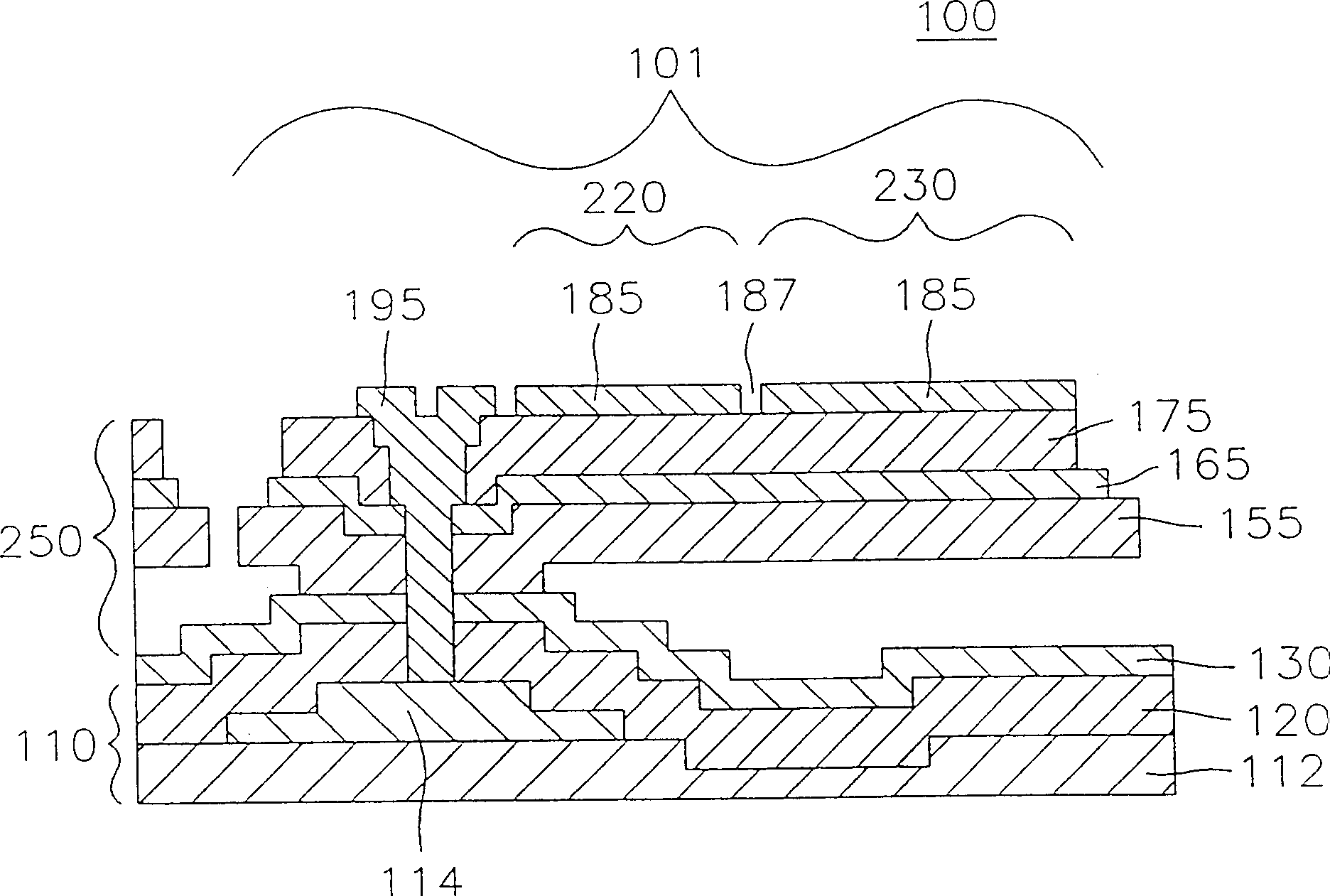

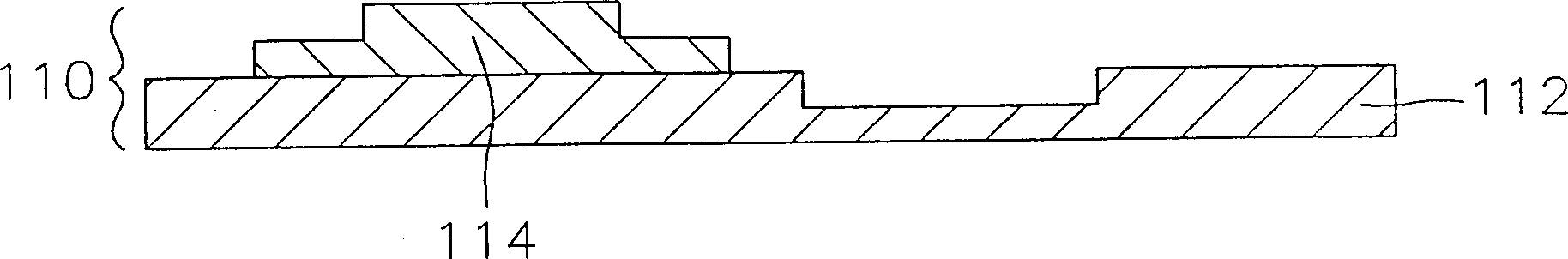

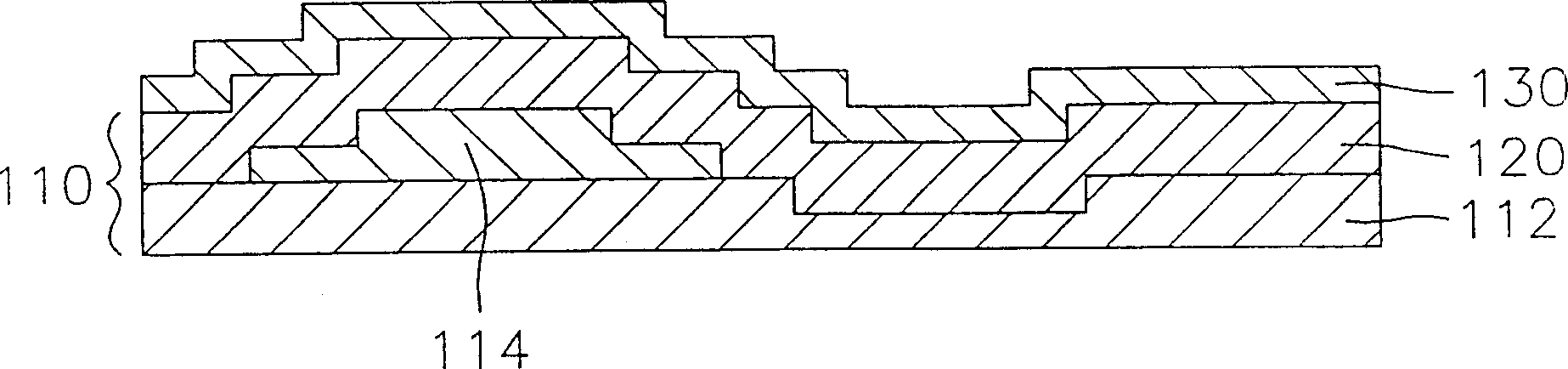

[0048] image 3 , 4A , 4B, 4C and Figures 5A-5M A cross-sectional view of an array 420 of M×N thin-film actuated mirrors 421 used in an optical projection system according to the present invention is respectively given, one along image 3 Schematic cross-sectional views of the array 300 of actuated mirrors 301 in line A-A and line B-B, one showing a cross-sectional view of a side actuator 430 of actuating mirror 301 and one showing a cross-sectional view of actuating mirror 301 A cross-sectional view of the central actuator 440 of , and a schematic cross-sectional view illustrating a method for fabricating an array 300 of M×N thin-film actuated mirrors 301 used in an optical projection system according to the present invention, where M and N is an integer. It should be noted that in image 3 , 4A , 4B, 4C and 5A-5M are denoted by like reference numerals.

[0049] Figure 4A In the figure, it is shown that the array 300 of the present invention includes an active matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com