An industrial chemical grinding equipment

A chemical grinding and equipment technology, applied in lighting and heating equipment, grain processing, dryers, etc., can solve the problems of grinding box bonding, increasing the viscosity of phosphate slurry, and easy deposition at the bottom of the grinding box, etc., to reduce Adhesive, quicker drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] as attached figure 1 to attach Figure 5 Shown:

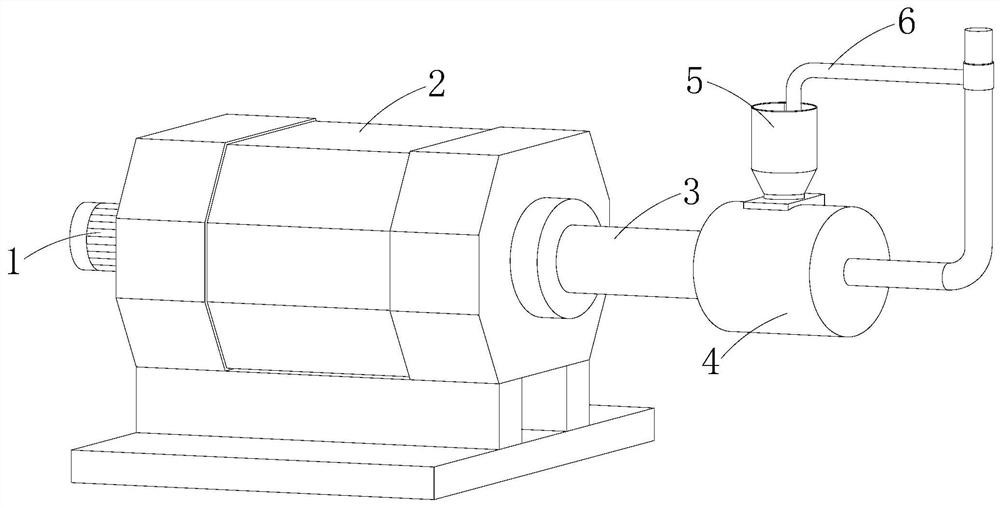

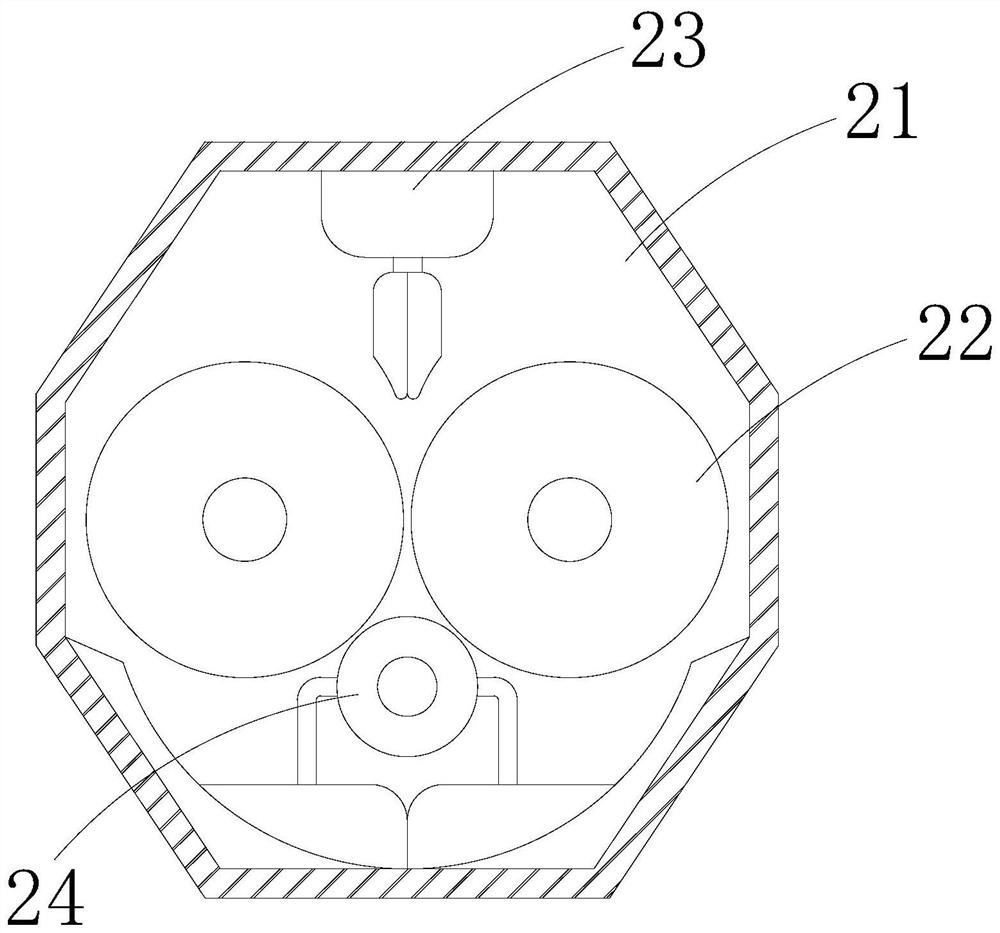

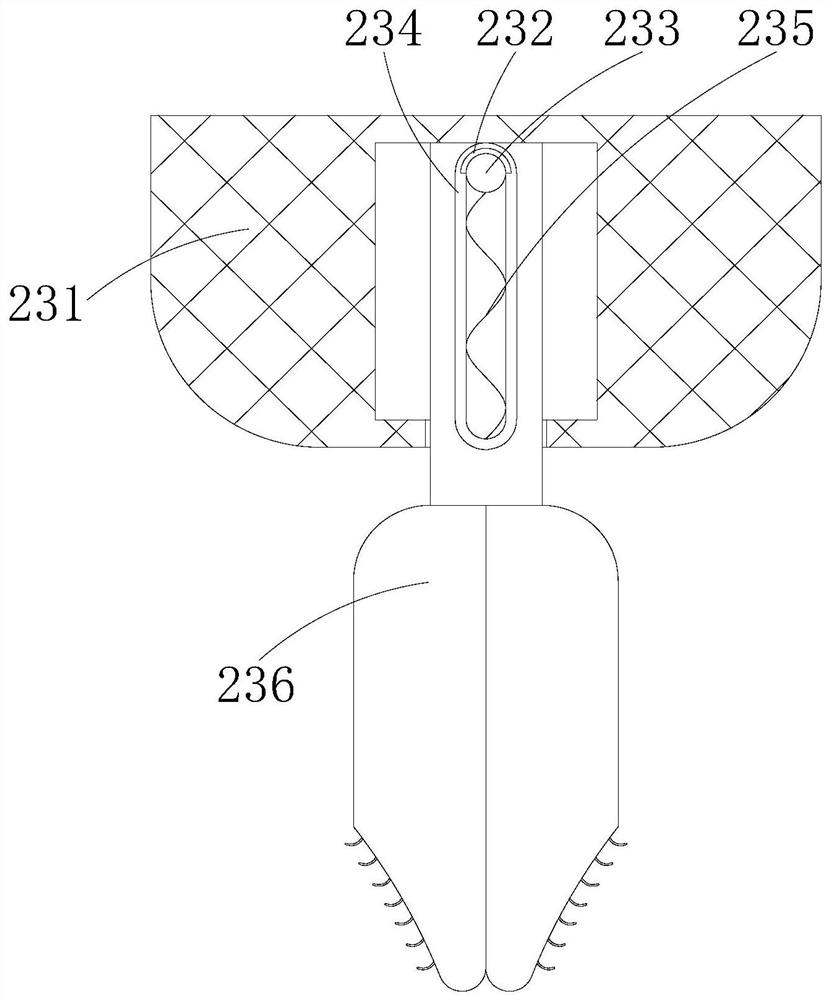

[0024] The present invention is an industrial chemical grinding equipment, the structure of which comprises a motor 1, a grinding box 2, a feeding pipe 3, a mixing pipe 4, a feeding hopper 5, and a water inlet pipe 6, and the motor 1 is fixedly mounted on the left end of the grinding box 2, The right end of the grinding box 2 is embedded with a feeding pipe 3 and communicates with each other. The right end of the feeding pipe 3 is provided with a mixing tube 4. The mixing tube 4 is fixed and connected with the lower end of the feeding hopper 5. The feeding A water inlet pipe 6 is installed inside the bucket 5, and the lower end of the water inlet pipe 6 communicates with the right end of the mixing pipe 4. The grinding box 2 includes a box body 21, a grinding roller 22, a sliding mechanism 23, and a toggle mechanism 24. The box body 21 A grinding roller 22 is fixedly installed inside, and the grinding roller 22 rotates...

Embodiment 2

[0030] as attached Image 6 to attach Figure 8 Shown:

[0031] Wherein, the toggle mechanism 24 includes a bottom plate 241 and a reverse reciprocating mechanism 242, the bottom surface of the bottom plate 241 is fixedly installed on the inside bottom of the box body 21, a reverse reciprocating mechanism 242 is arranged above the bottom plate 241, and the reverse reciprocating mechanism 242 The mechanism 242 is located below the grinding roller 22. The upper end of the bottom plate 241 has an inclined structure, and the upper surface has an arc-shaped structure, which facilitates the flow of phosphate slurry on the bottom plate 241 and reduces the adhesion of the phosphate slurry to the surface of the bottom plate 241.

[0032] Wherein, the reverse reciprocating mechanism 242 includes a connecting roller 421, a rotator 422, a rope 423, a sliding rod 424, a guide rod 425, a spring 426, and a dial 427. The connecting roller 421 is located above the bottom plate 241, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com