Seismic steel-wood frame structure system and its construction method

A technology of wood frame and anti-seismic steel, which is applied in anti-seismic, building components, building structures, etc., can solve the problems of poor anti-bending effect, weak building joint strength, and poor anti-seismic performance, so as to achieve strong integrity and anti-seismic structure Strong energy consumption and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

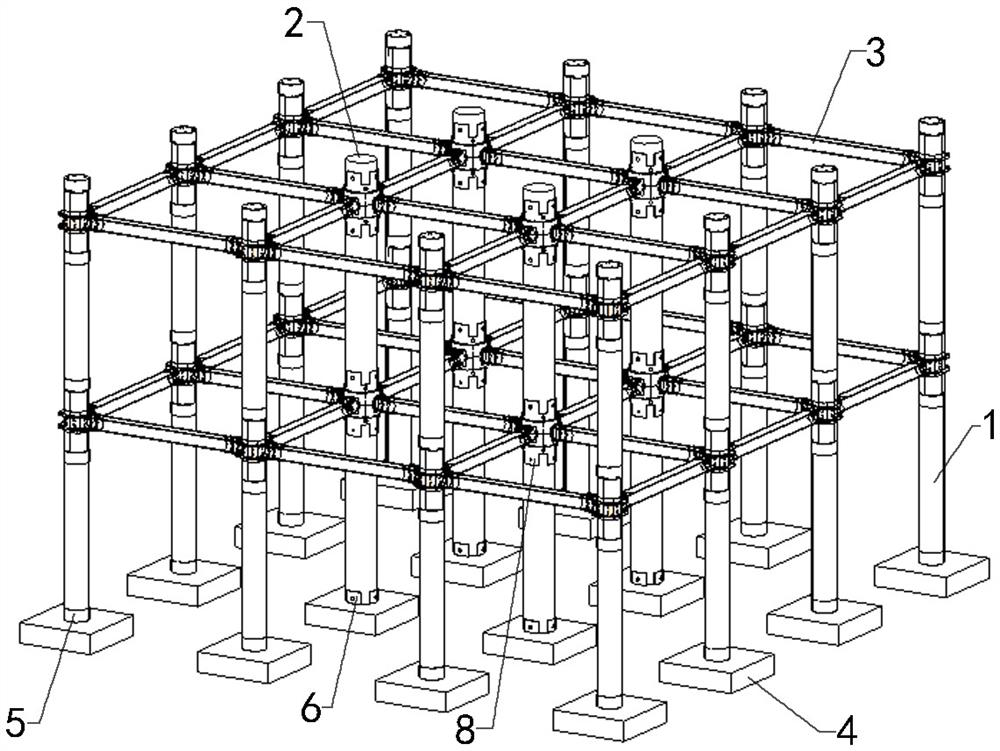

[0050] Such as figure 1 As shown, the new anti-seismic steel-wood frame structure system of the present invention includes a bending-resistant wooden column 1 located on the periphery of the building, a load-bearing wooden column 2 located inside the bending-resistant wooden column 1, and wooden beams connecting adjacent wooden columns on the same floor 3.

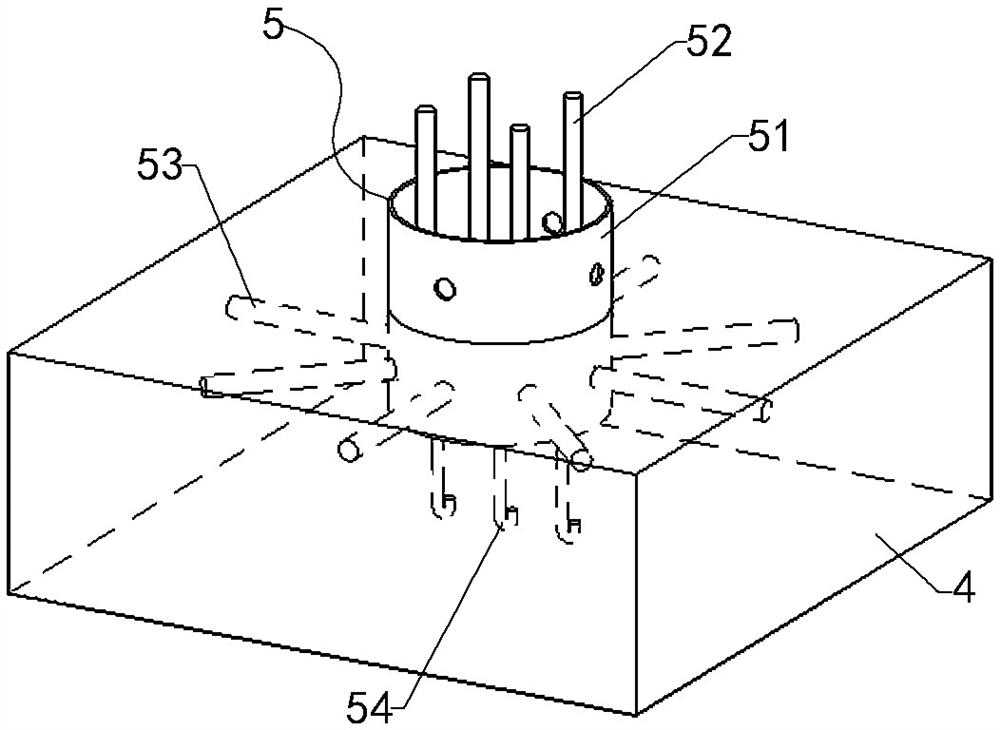

[0051] The interior of the bending-resistant wooden column 1 is provided with a full-length tunnel for piercing the reinforcement along the axial direction, and the built-in steel bars 11 are pierced in the tunnel, and the built-in steel bars 11 are fixed to the bending-resistant wooden column 1 by gluing. Design according to the requirements of the structural stress, and evenly distribute in the cross-section of the bending-resistant wooden column 1. The bottom of the bending-resistant wooden column 1 is fixedly connected with the independent foundation 4 through the rigid joint assembly 5, and the independent foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com