A kind of high temperature resistant cable and its production process

A high-temperature-resistant and high-temperature-resistant layer technology is applied in the manufacture of cables, insulated cables, and cables/conductors. It can solve problems such as poor connection stability, and achieve the effect of not being easy to sag, not easy to tighten, and improving the stability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

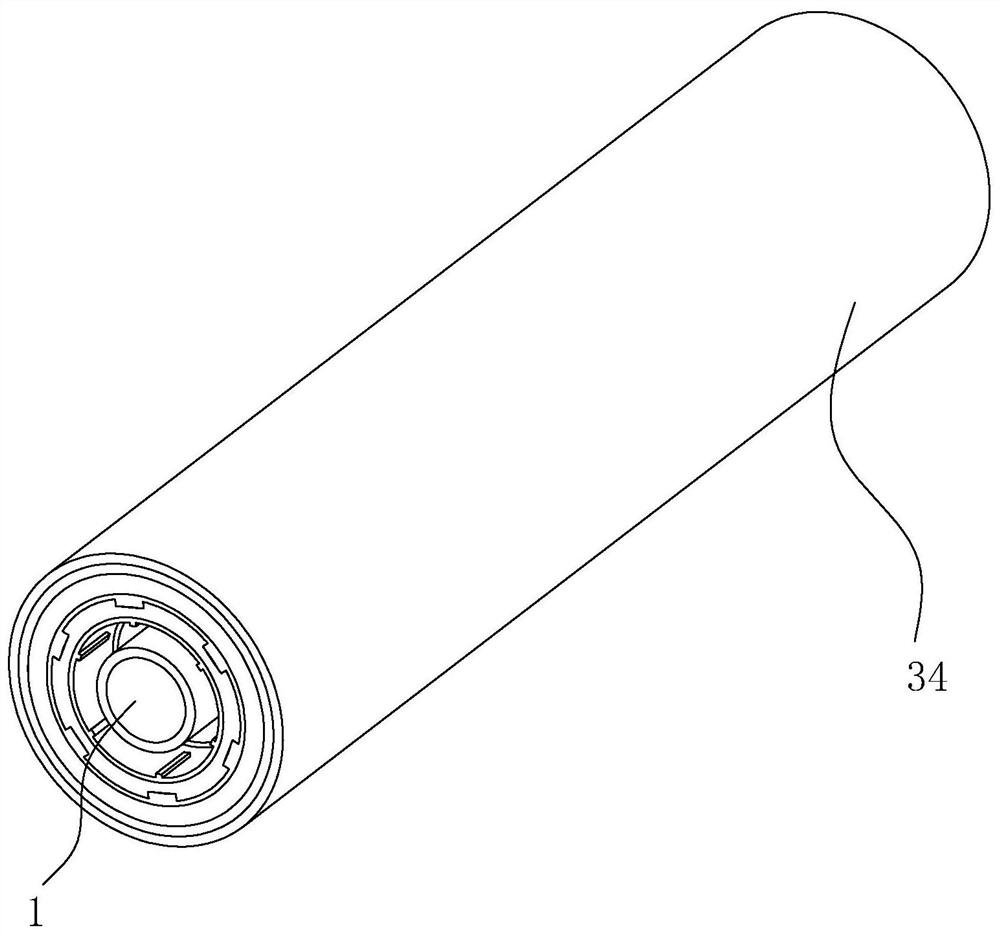

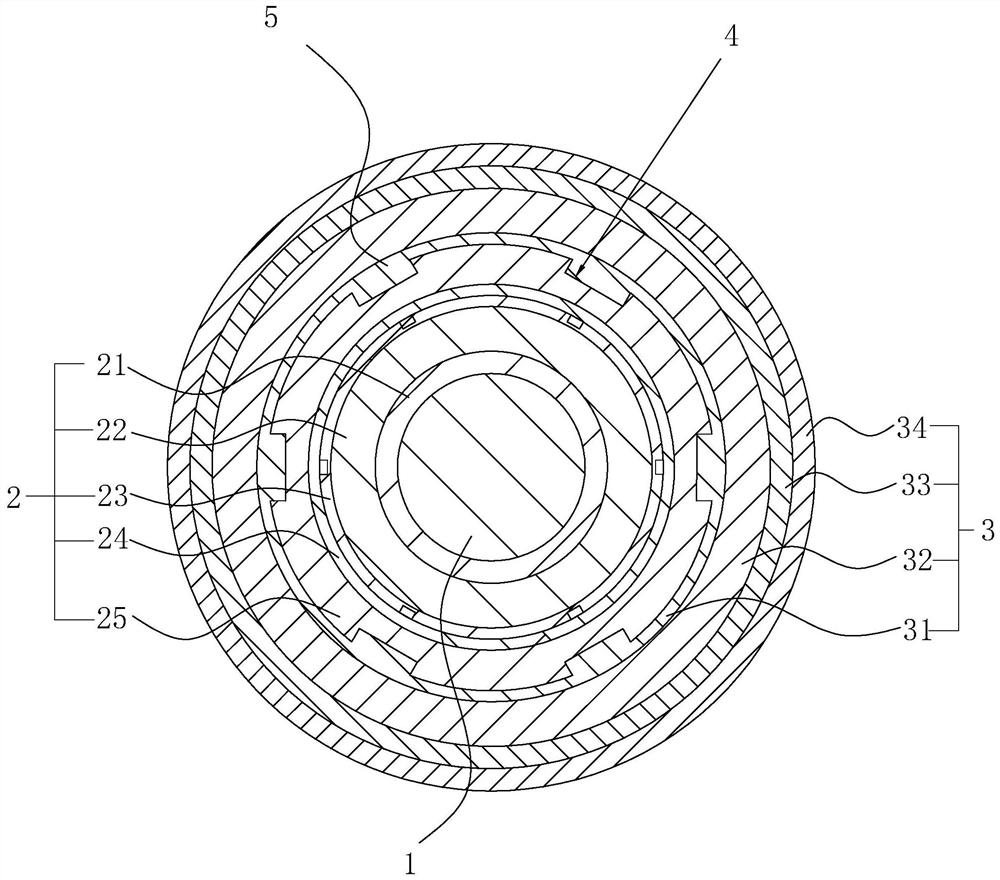

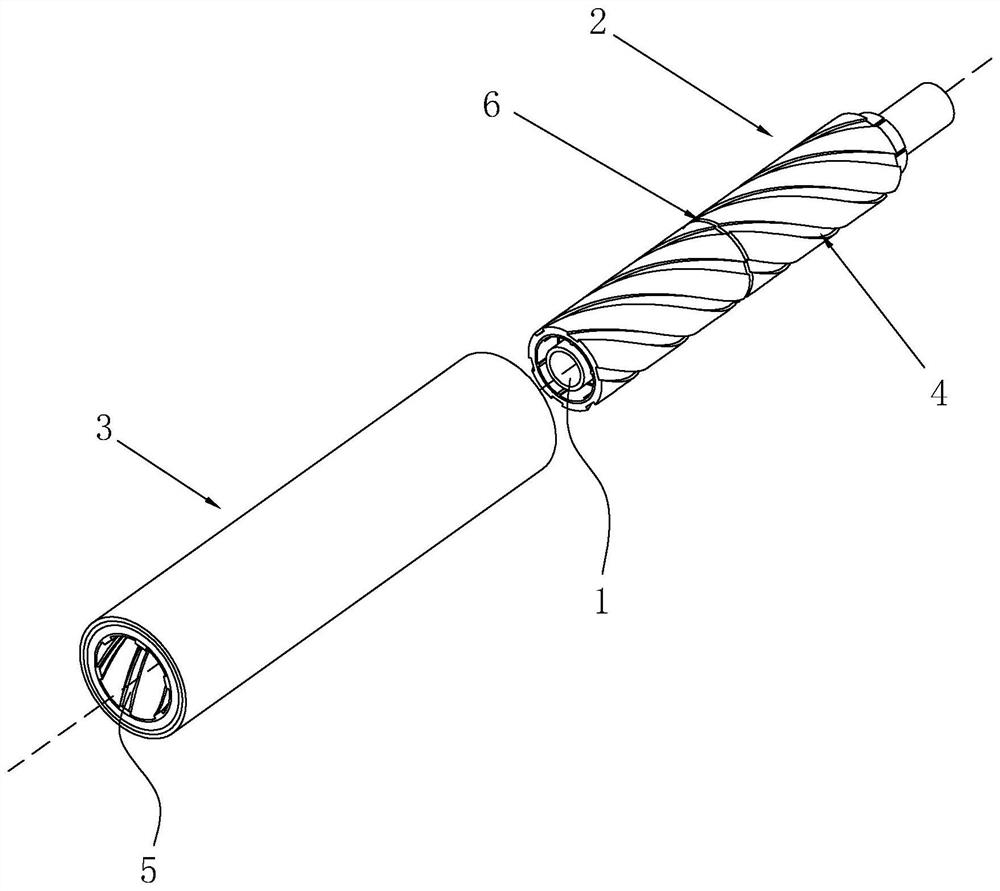

[0036] combine figure 1 with figure 2, is a high temperature resistant cable disclosed by the present invention, including a core 1, a protective layer 2 and a high temperature resistant layer 3 are arranged on the outer side of the core 1, the protective layer 2 is placed on the side close to the core 1, and the protective layer 2 The card slot 4 is formed by indenting toward the direction close to the wire core 1, and the position where the high temperature resistant layer 3 is facing the card slot 4 protrudes toward the direction of the card slot 4 and forms a card bar 5 that is plugged and adapted to the card slot 4, and the card slot 4 and The mutual cooperation of the clip strips 5 strengthens the connection between the protective layer 2 and the high temperature resistant layer 3, so as to achieve the effect of improving the stability of the cable during use.

[0037] refer to figure 2 The protective layer 2 includes an insulating varnish layer 21, a rubber particle...

Embodiment 2

[0043] A production process for high temperature resistant cables, comprising the following steps:

[0044] S1, apply the insulating varnish evenly on the surface of the wire core 1, and smoothen the outer surface of the insulating varnish applied on the surface of the wire core 1;

[0045] S2, glue the rubber particle coagulation layer 22, glass fiber layer 23, polytetrafluoroethylene layer 24 and quartz layer 25 together layer by layer from inside to outside, and make the rubber particle coagulation layer 22 and glass fiber layer 23 at one end extend outward Form the overlapping layer 7, so that the polytetrafluoroethylene layer 24 and the quartz layer 25 at the other end extend outward to form the connecting layer 8;

[0046] S3, bonding the heat-conducting silicone grease layer 31, the heat-conducting silica gel layer 32, the refractory clay layer 33 and the ceramic fiber layer 34 together layer by layer from inside to outside;

[0047] S4, set the rubber particle coagula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com