Preparation method of organic crystalline thin film and organic field effect transistor

An organic and crystalline technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as difficult to achieve consistent single crystal orientation, low resolution, and difficult organic crystal consistency. It is conducive to the promotion and use of large areas, easy to control, and simple to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

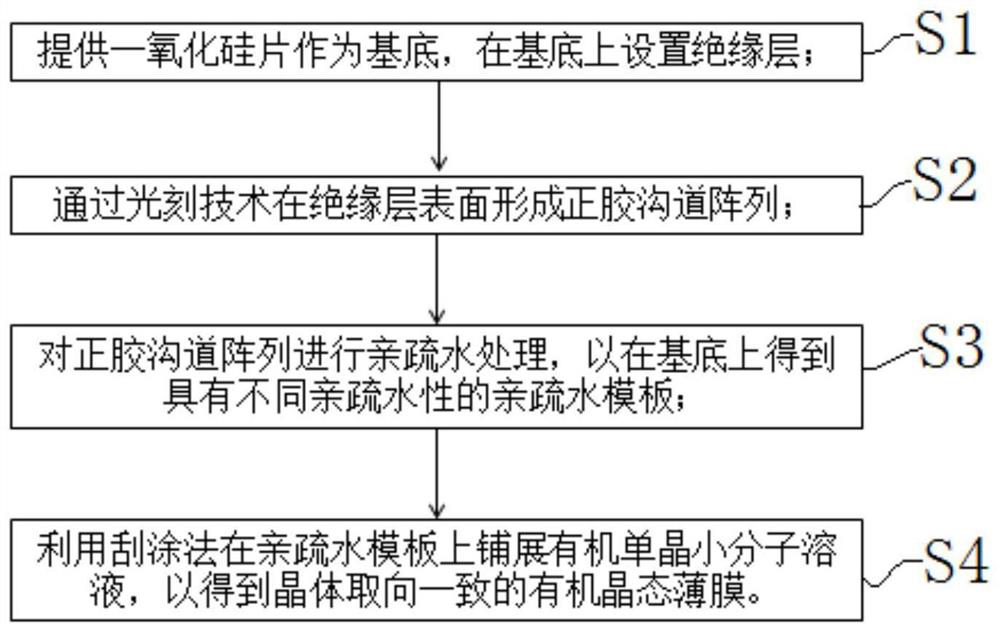

[0060] The preparation method of the organic crystalline thin film of the present invention comprises the following steps:

[0061] S1. Provide a silicon oxide wafer as a substrate, and set an insulating layer on the substrate;

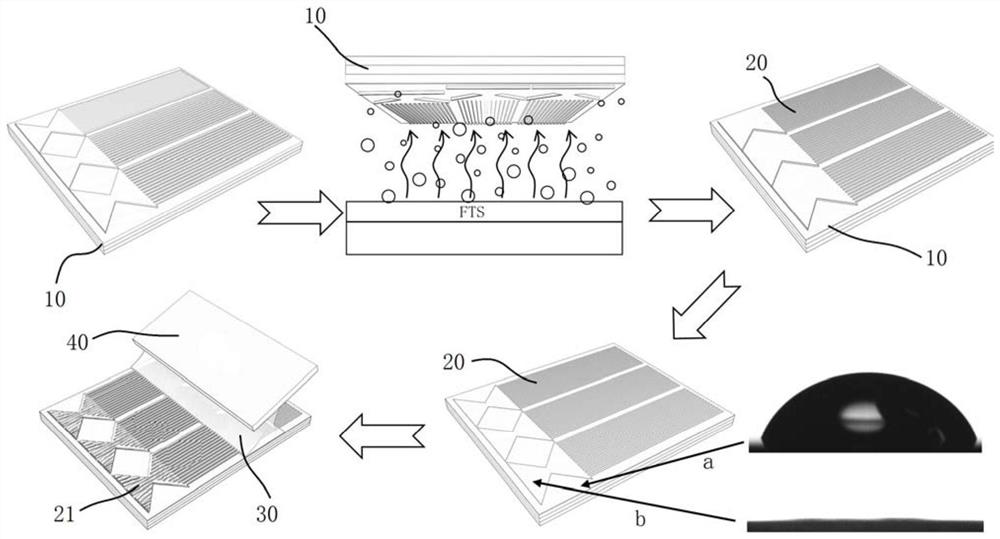

[0062] S2. A positive resin channel array is formed on the surface of the insulating layer by photolithography; the end of the positive resin channel array is a periodically changing hourglass-shaped structure, which is used to filter the crystal orientation, so that the crystals with the same orientation are The two sides of the hourglass-shaped structure are epitaxially grown and entered into the positive glue channel array;

[0063] S3, performing hydrophilic and hydrophobic treatment on the positive glue channel array to obtain hydrophilic and hydrophobic templates with different hydrophilic and hydrophobic properties on the substrate;

[0064] S4, spread the organic single crystal small molecule solution on the hydrophilic and hydrophobic template...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com