Linear motor

A linear motor and coil set technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of normal and stable operation of unfavorable equipment, large fluctuation range of driving force, low utilization efficiency of permanent magnets, etc. Narrow, practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

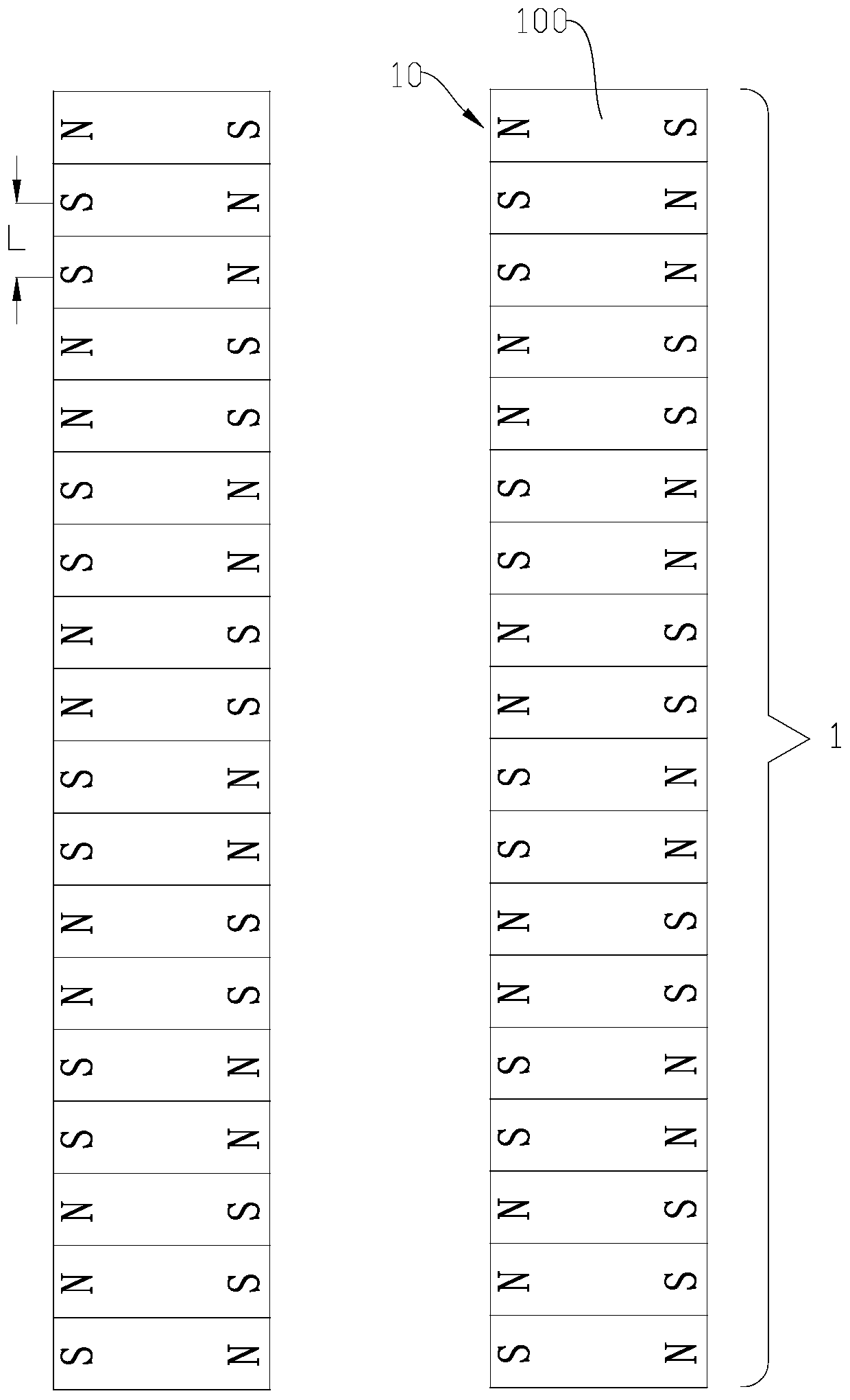

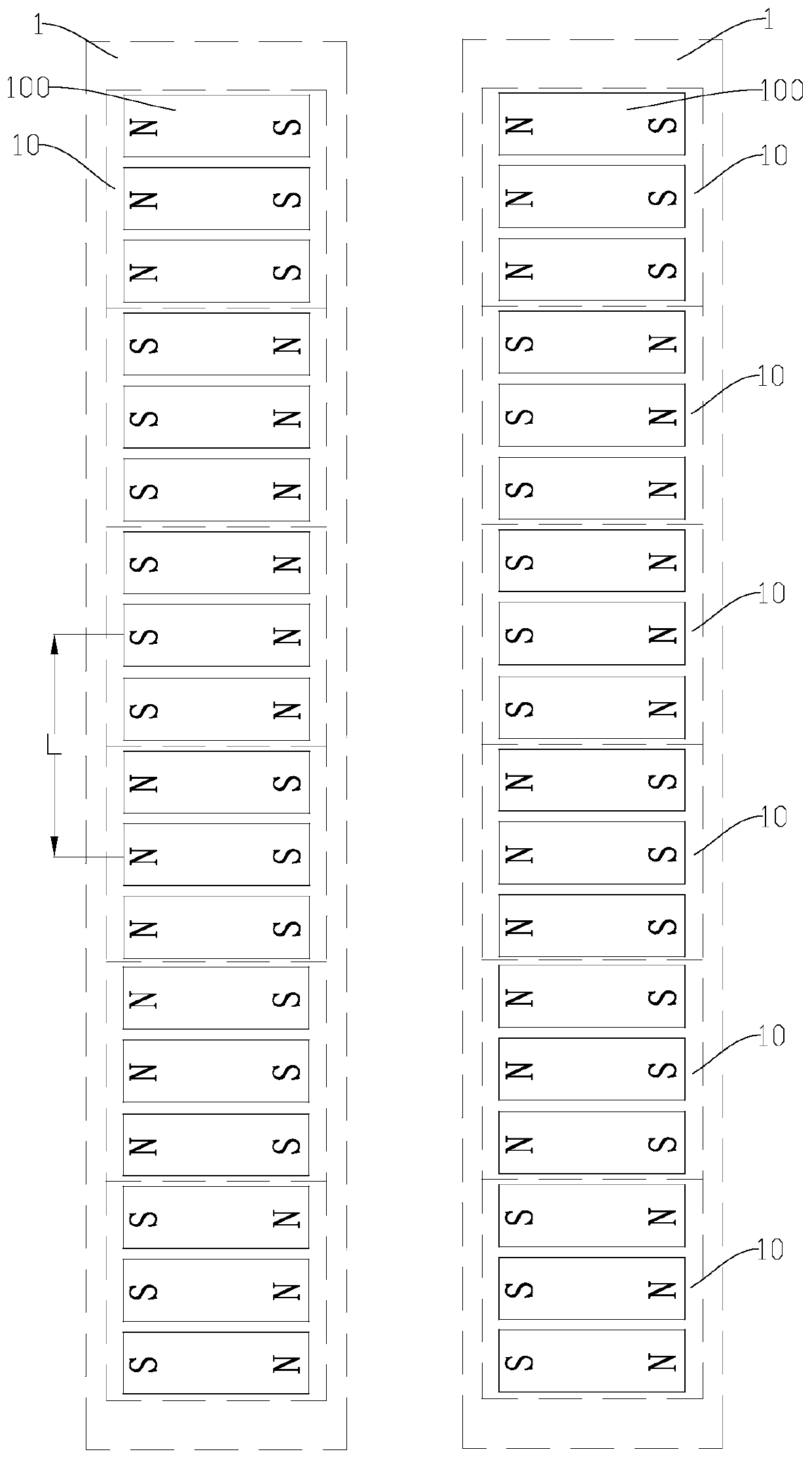

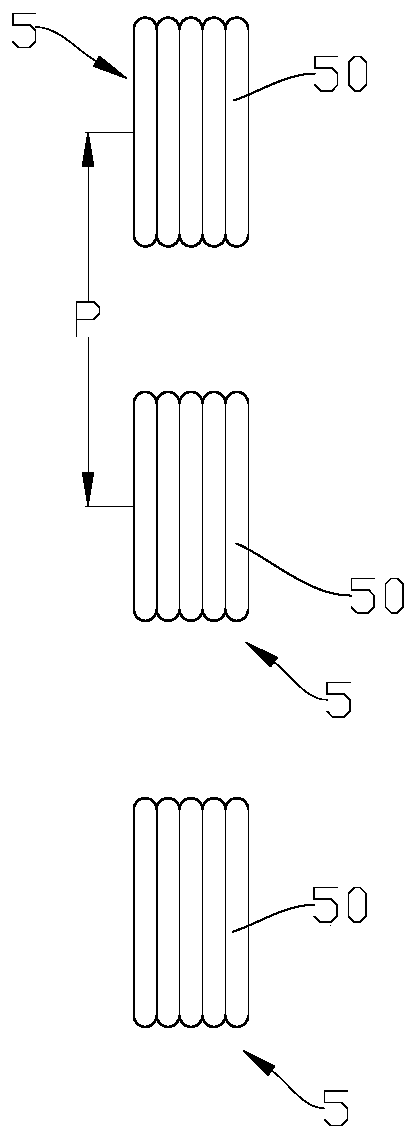

[0033] Such as Figure 1 to Figure 7 As shown, a linear motor includes a mounting mechanism 3, a plurality of permanent magnet monomers 100 of the same specification are fixedly connected to the mounting mechanism 3, and at least one of the permanent magnet monomers 100 is arranged side by side to form a permanent magnet Group 10, the magnetic poles of all permanent magnet monomers 100 in the permanent magnet group 10 are arranged on the same side of the same polarity to form N poles and S poles of the permanent magnet group 10, and at least four permanent magnet groups 10 are arranged side by side along a straight line Arranging to form a permanent magnet row 1, the permanent magnet row 1 has two and distributed in parallel, the magnetic poles at both ends of all the permanent magnet groups 10 in the permanent magnet row 1 are arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap