Filter device

A technology of screening device and sieve, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large construction height and limited product transfer, and achieve the effect of saving construction height, reducing construction height and optimizing the screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

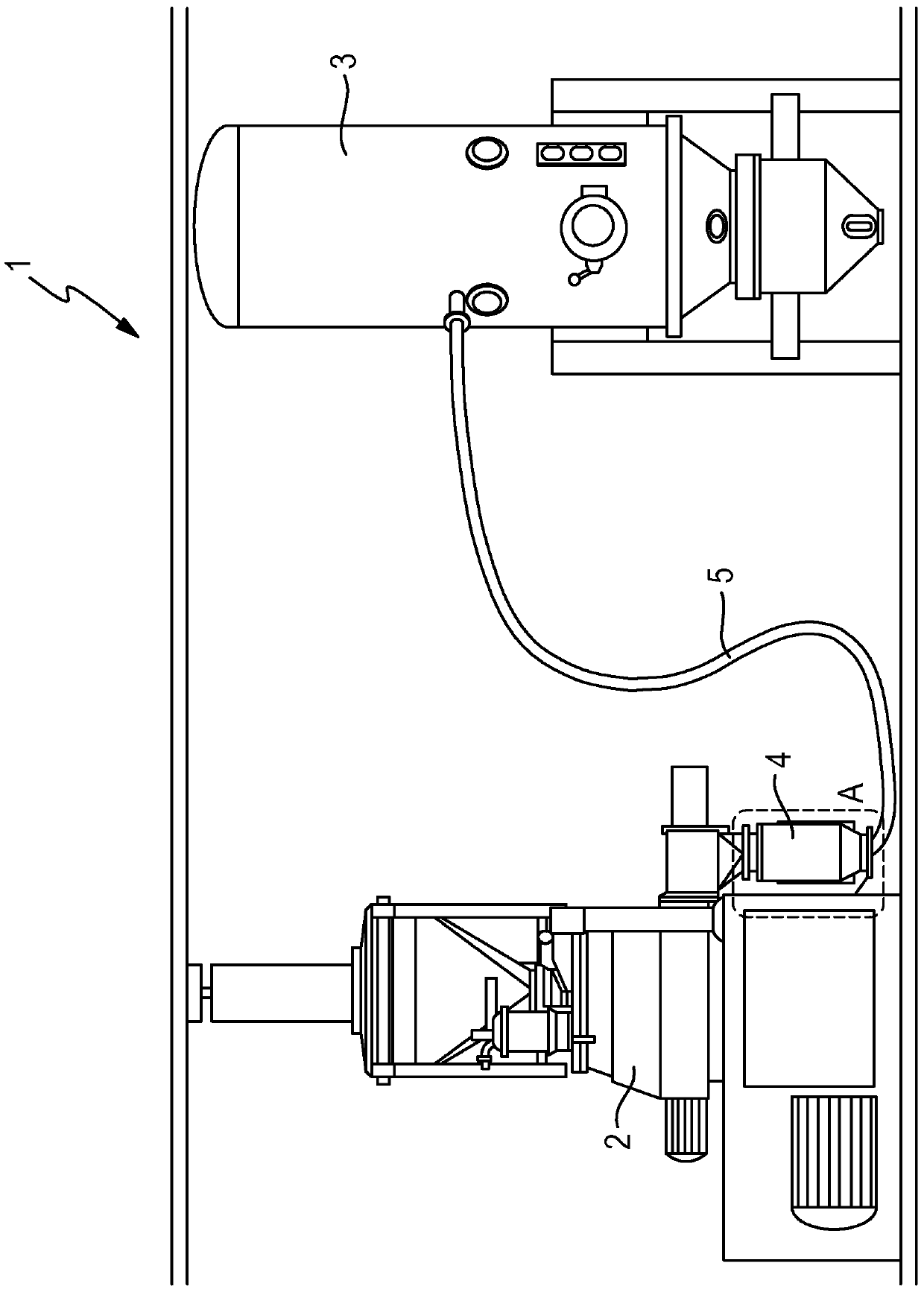

[0025] exist figure 1 A simple schematic illustration of the principle structure of a granulation line 1 known from the prior art is shown in . In order to transfer wet pellets eg from the high shear granulator 2 into the dryer 3, the pellets need to be transferred. This transfer is currently carried out either by gravity feeding of the dryer 3 or by pneumatic conveying. In the case of gravity feeding, the pellets fall into the dryer 3 driven by their own mass. However, this type of feeding requires a large construction height and a spatially feasible realization of the pelletizing line 1 . exist figure 1 In the case of the granulation line 1 shown in , between the high shear granulator 2 and the dryer 3 a screening device 4 at the outlet of the high shear granulator 2 is shown. The outlet of the screening device 4 is connected to the dryer 3 via a flexible hose line 5 .

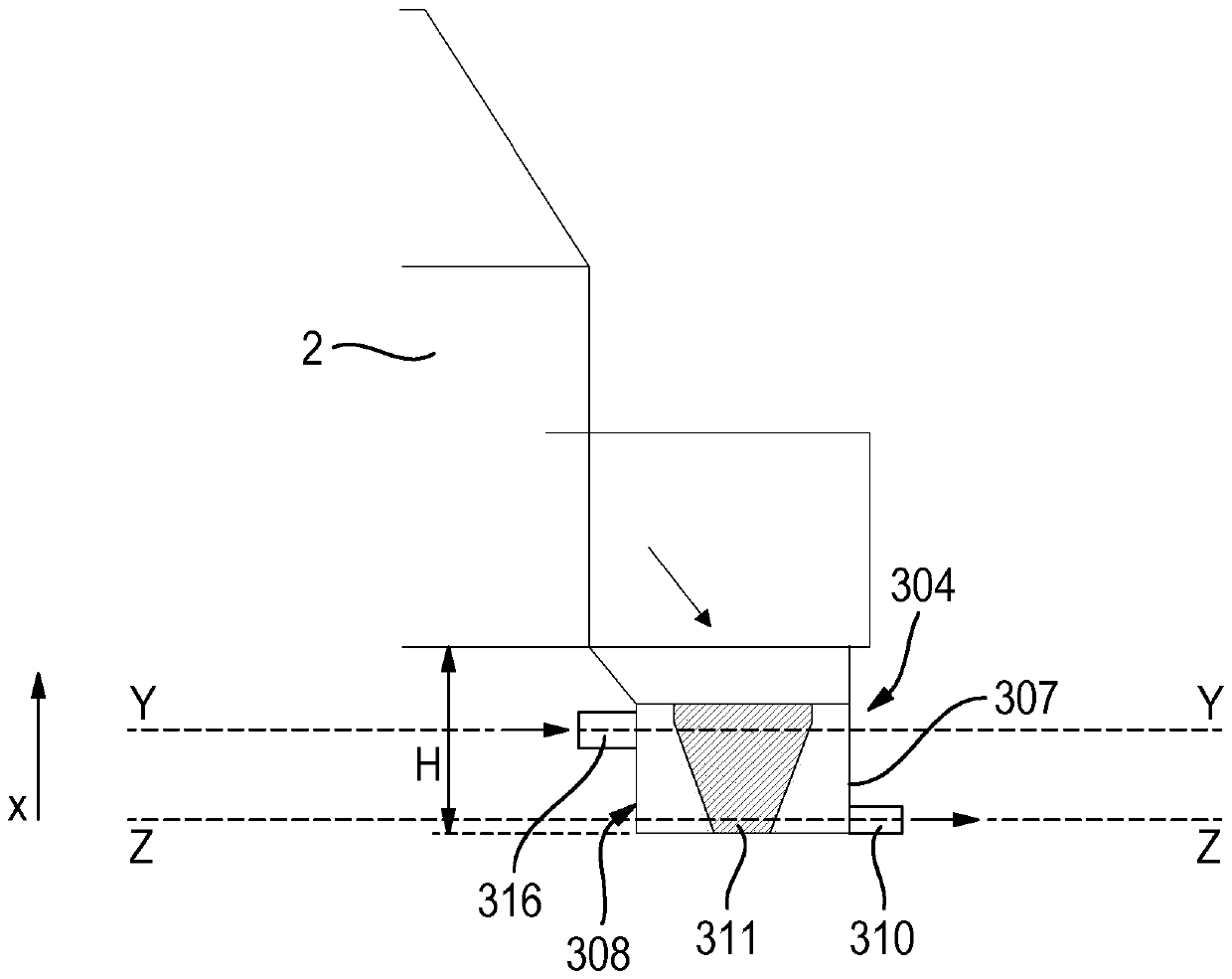

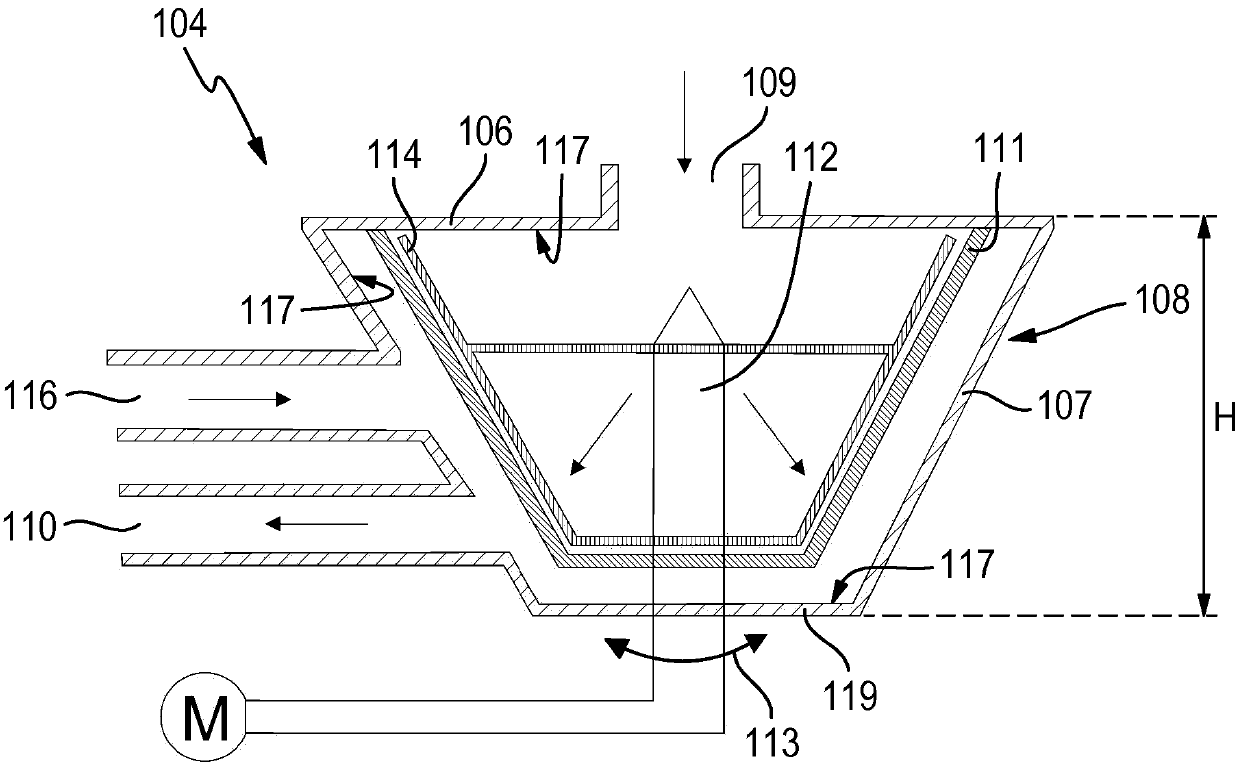

[0026] figure 2 Shows the basis for the screening device 4 known from the prior art figure 1 A cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com