Centrifugal pendulum device with a diaphragm spring for generating frictional resistance, clutch plate, and powertrain

A technology of centrifugal force pendulum and disk spring, which is applied in the field of drive system and can solve the problems of contact element wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

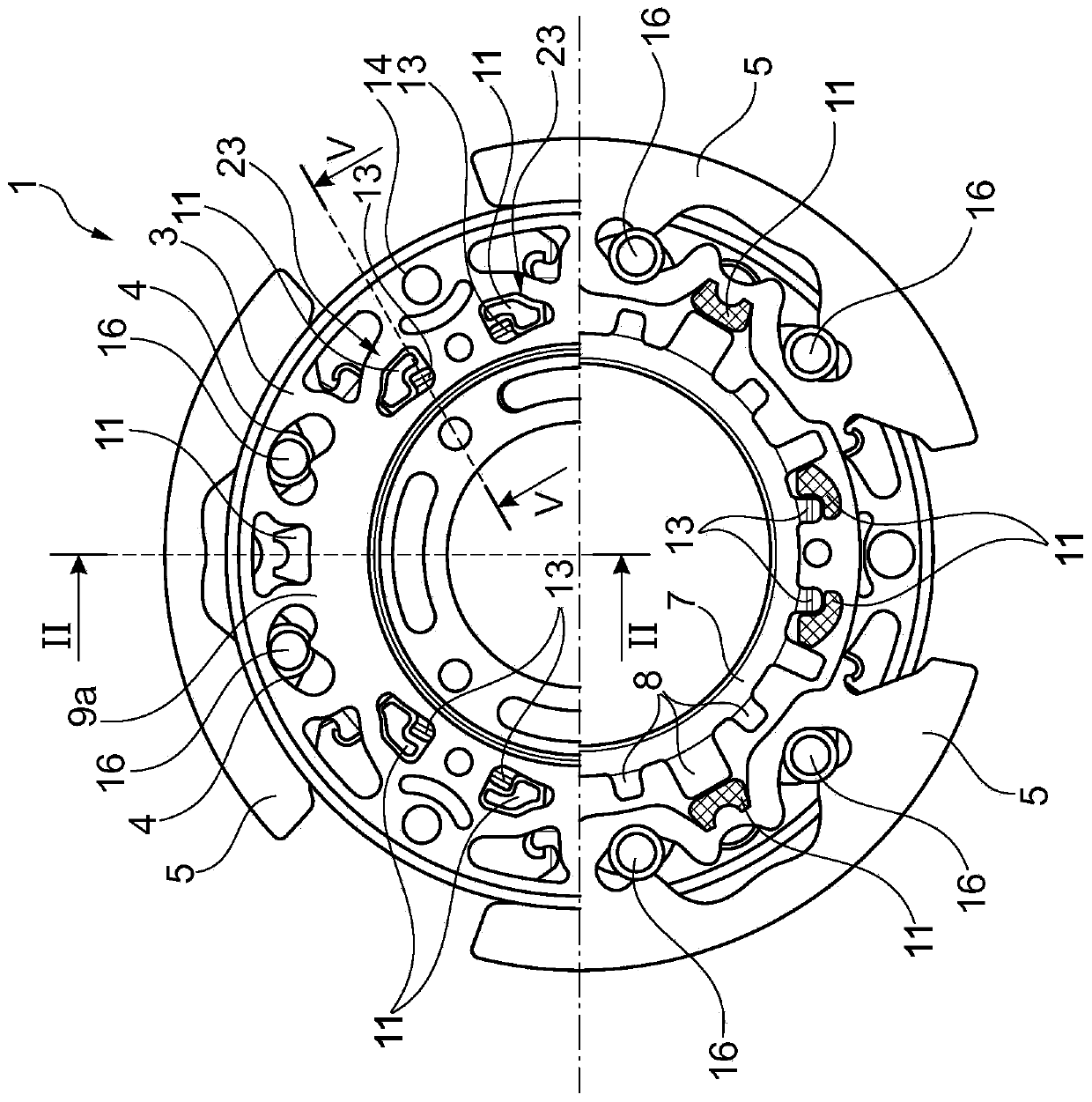

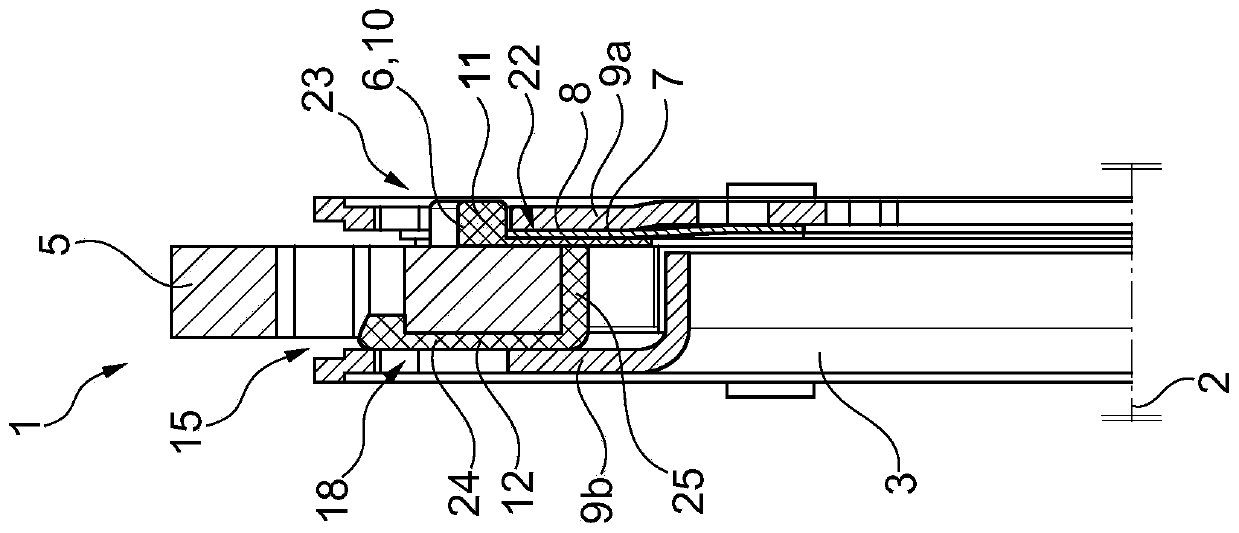

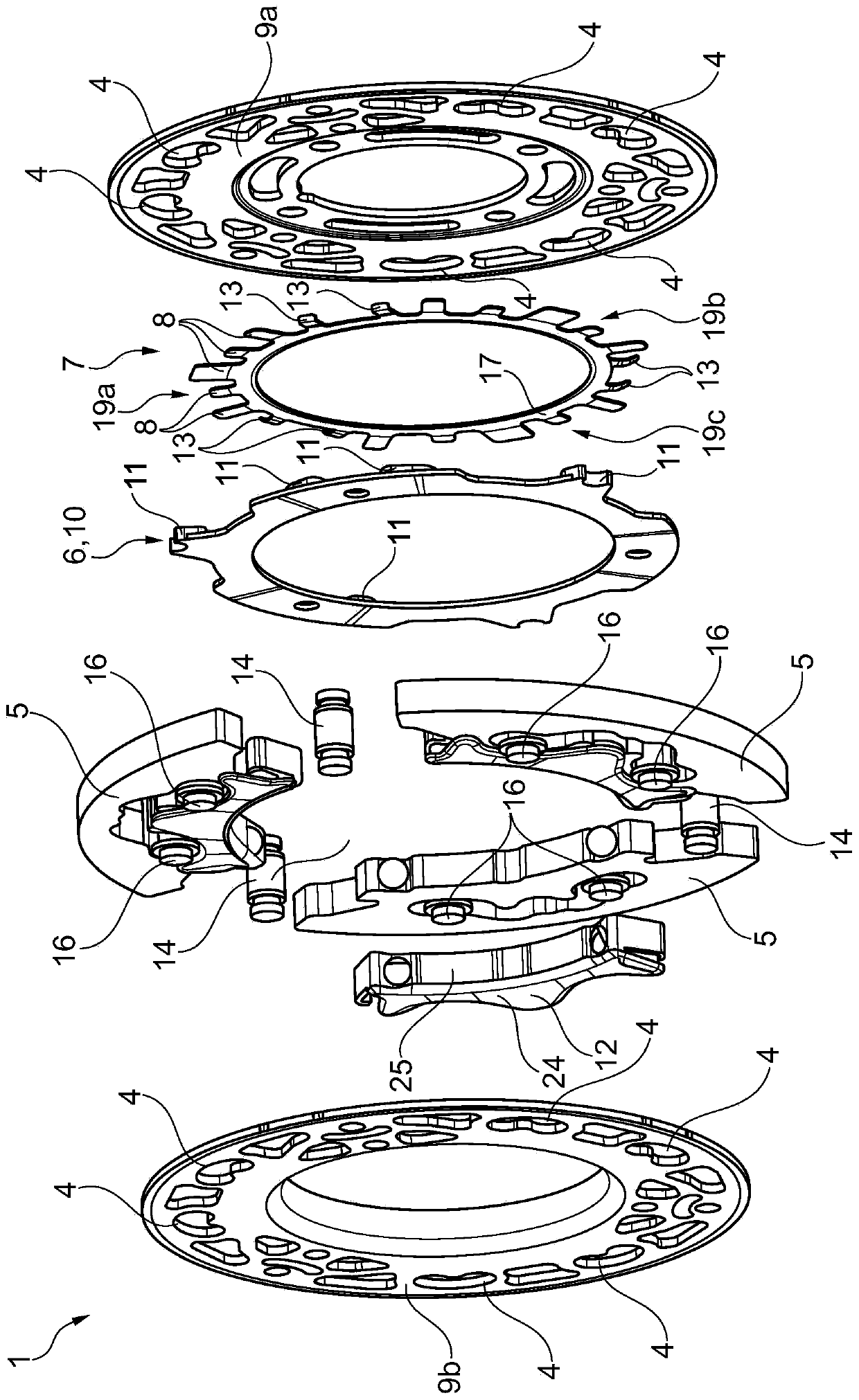

[0063]The friction device 18 in the centrifugal pendulum 1 has the function of reducing the large vibration angle of the pendulum mass 5 . The disk spring 7 serves here as an energy store / force source. The disk spring 7 is arranged between the pendulum mass 5 and the flatter of the two flanges (first support area 9a (smaller axial extent than the second support area 9b)) and projects radially inwards into the gap 22 between the two flanges 9a, 9b. This makes use of this space in order to achieve a function-optimized spring characteristic curve. The disc spring 7 has a plurality of outer tongues 8 , 13 . The more strongly curved outer tongue 13 has the function of centering the disk spring 7 in the centrifugal pendulum 1 , positioning the disk spring 7 during assembly of the centrifugal pendulum and transmitting force in the circumferential direction to the flange 9 a. The tongue 8 which is only slightly bent transmits the spring force via the friction rings 6 , 10 to the in...

Embodiment approach 2

[0065] Another conceivable variant is that the friction ring 6 is made of sheet metal or is embodied as a support disk (support element 26 ).

Embodiment approach 3

[0067] Another conceivable variant is to arrange annular friction rings 6 , 10 on both sides of pendulum mass 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com