Scenting process for improving smoking quality of tobacco products

A tobacco product and scenting technology, applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problem of not being able to obtain characteristic aroma, achieve the effects of improving smoking quality, rich and mellow aroma, and prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

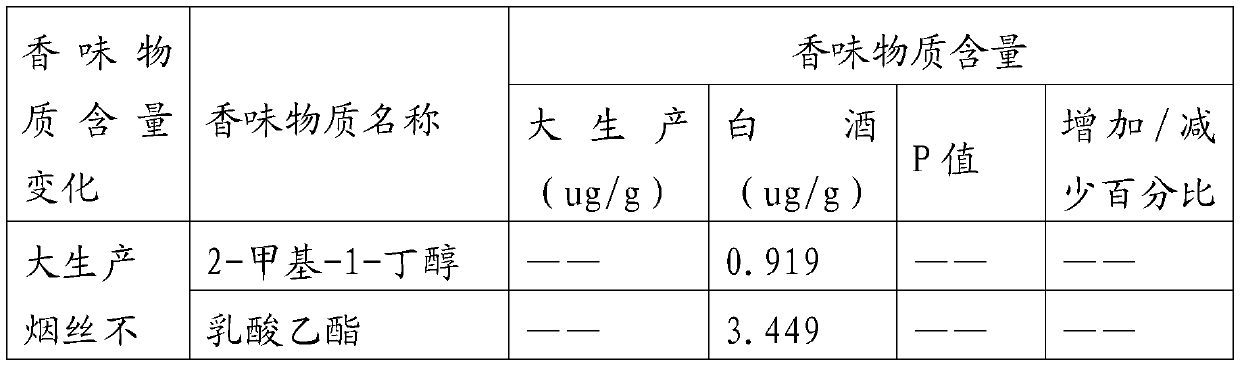

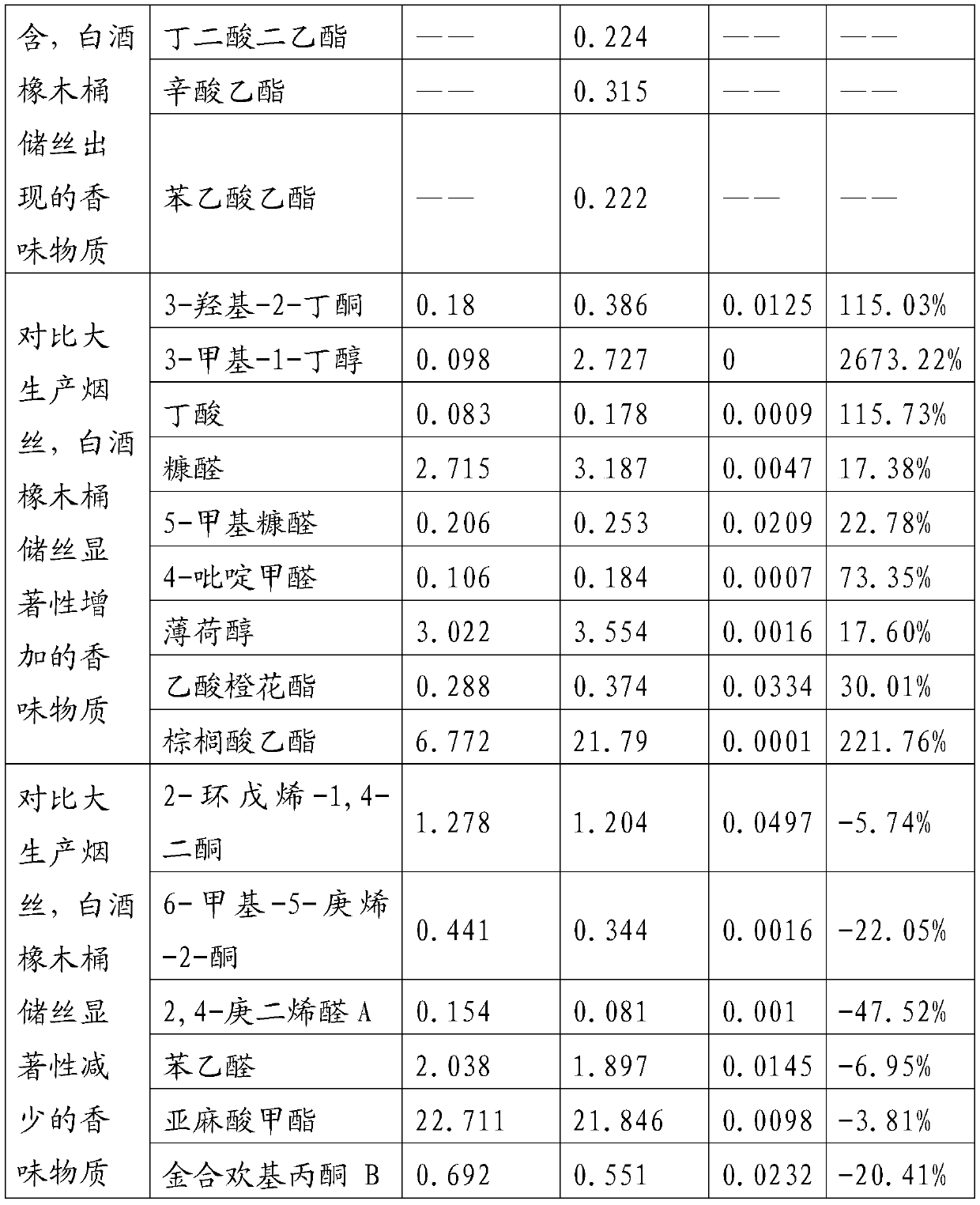

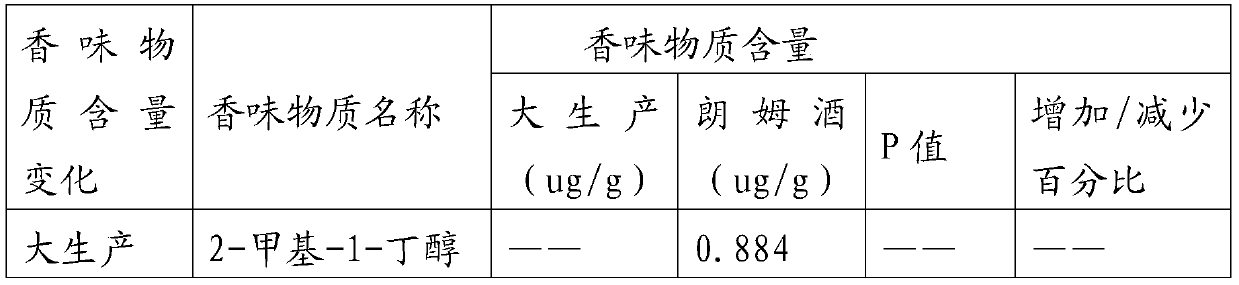

[0032] Place the oak barrel in a ventilated and shaded room with an ambient temperature of 15°C and a humidity of 60%, and use white wine and rum to raise the barrel: use a watering can to spray 250mL of wine evenly on the inner wall of the oak barrel and the inside of the lid every day for 7 consecutive days . The processed oak barrels are moved to a silk storage room with an ambient temperature of 25°C and a humidity of 62%, and left to stand for 5 days to balance the humidity inside and outside the barrel. Then the shredded tobacco was stored in oak barrels, covered and scented for 7 days, and the shredded tobacco in the oak barrels were taken out for analysis of aroma components. The results are as follows:

[0033] 1. The total amount of aroma substances in cut tobacco after storage in oak barrels treated with white wine and rum increased by 4.35% and 4.98% respectively compared with large-scale production of cut tobacco;

[0034] 2. Use white wine oak barrels to store s...

Embodiment 2

[0047] Place the oak barrels in a ventilated and shading room, keep the ambient temperature at 15°C, and the humidity at 60%. The walls of the room are evenly coated with cellar mud containing compound strains, and 250mL of whiskey with an alcohol content of 15% is evenly sprayed on the oak barrels every day using a watering can. Spray the inner wall and the inside of the cover continuously for 7 days. The processed oak barrels are moved to a silk storage room with an ambient temperature of 25°C and a humidity of 62%, and left to stand for 5 days to balance the humidity inside and outside the barrel. The tobacco leaves are then stored in oak barrels, covered and scented for 7 days. The special aroma released from the oak barrels can be taken out after being fully absorbed by the tobacco leaves, shredded and rolled into cigarette sample A for sensory evaluation.

[0048] Tobacco leaves stored in oak barrels that have not been treated by microorganisms and only treated with whis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com