a preparation ti 2 Alnb/ti60 double alloy disk method

A double-alloy and alloy technology, which is applied in design optimization/simulation, CAD numerical modeling, special data processing applications, etc., can solve the problems of double-alloy disk joint defects, poor weldability, difficult homogenization and microstructure refinement, etc. , to achieve the effect of eliminating joint surface defects, solving poor weldability and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

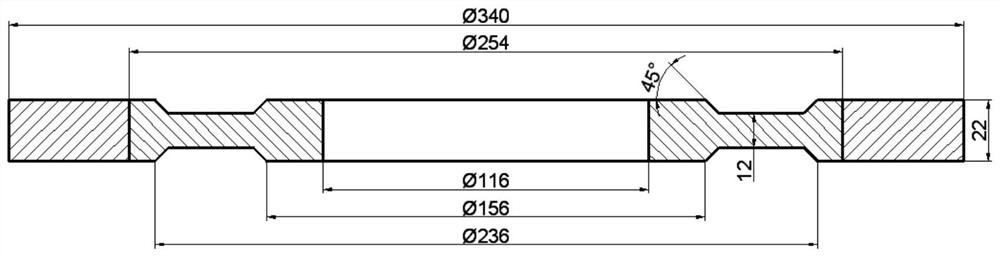

[0030] Such as figure 1 A Ti with a size of Φ340mm×24mm (connection interface position Φ254mm±2mm) is shown 2 AlNb / Ti60 double alloy dish, the preparation steps of adopting the method of the present invention are as follows:

[0031] 1. Select Ti with a particle size of 53 μm to 150 μm 2 AlNb alloy powder is loaded into a steel sheath through the powder filling port, and then subjected to hot isostatic pressing after compaction, vacuum degassing, sealing welding, hot isostatic pressing parameters: 1020°C / 140MPa / 2h, and Ti 2 AlNb powder alloy, hot isostatic pressing placed Ti60 alloy bar with the furnace, Ti after hot isostatic pressing 2 A sample of Φ8mm×12mm was taken from the AlNb powder alloy and Ti60 alloy rod for thermal compression test to obtain the stress-strain curve, based on which the Ti 2 Material constitutive model of AlNb powder alloy and Ti60 alloy;

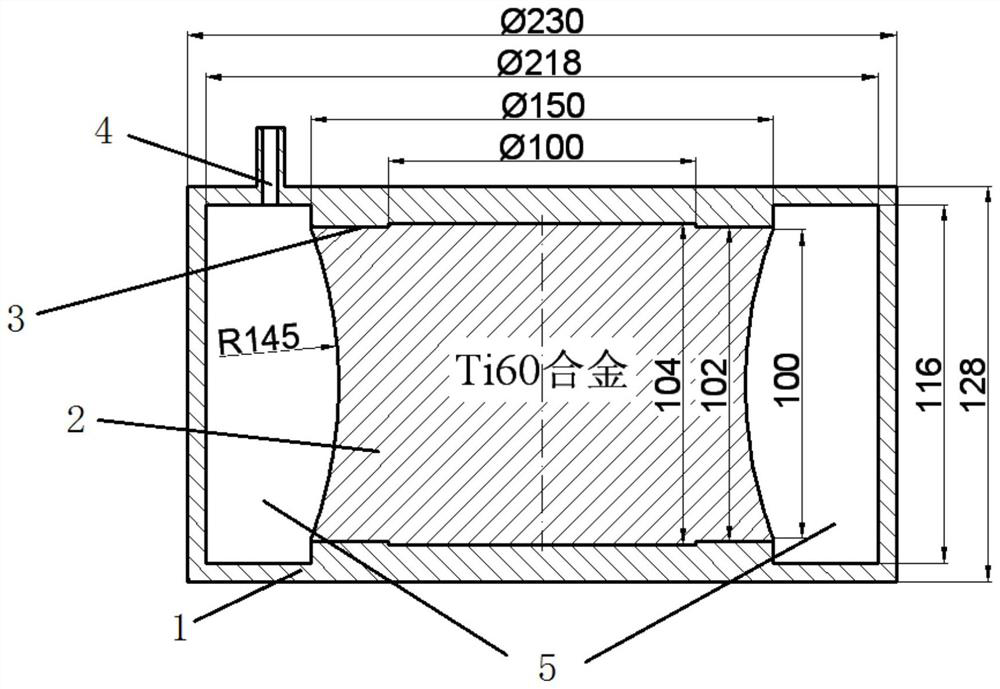

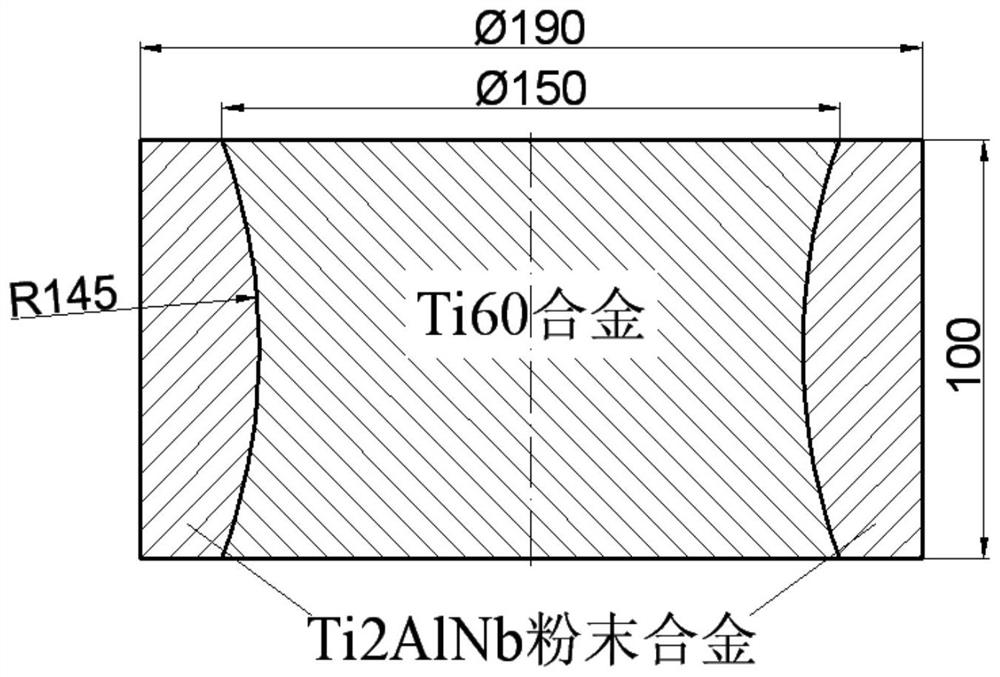

[0032] 2. Design Ti according to the structural size of the double alloy disc 2 The geometric structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com