Substrate polishing system

A substrate and grinding layer technology, which is applied to grinding devices, grinding machine tools, and parts of grinding machine tools, can solve problems such as the inability to grasp the grinding layer of the substrate in real time, and the inability to accurately measure the thickness of the grinding layer in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings. In describing the present invention, in order to clarify the gist of the present invention, detailed descriptions of well-known functions or configurations are omitted.

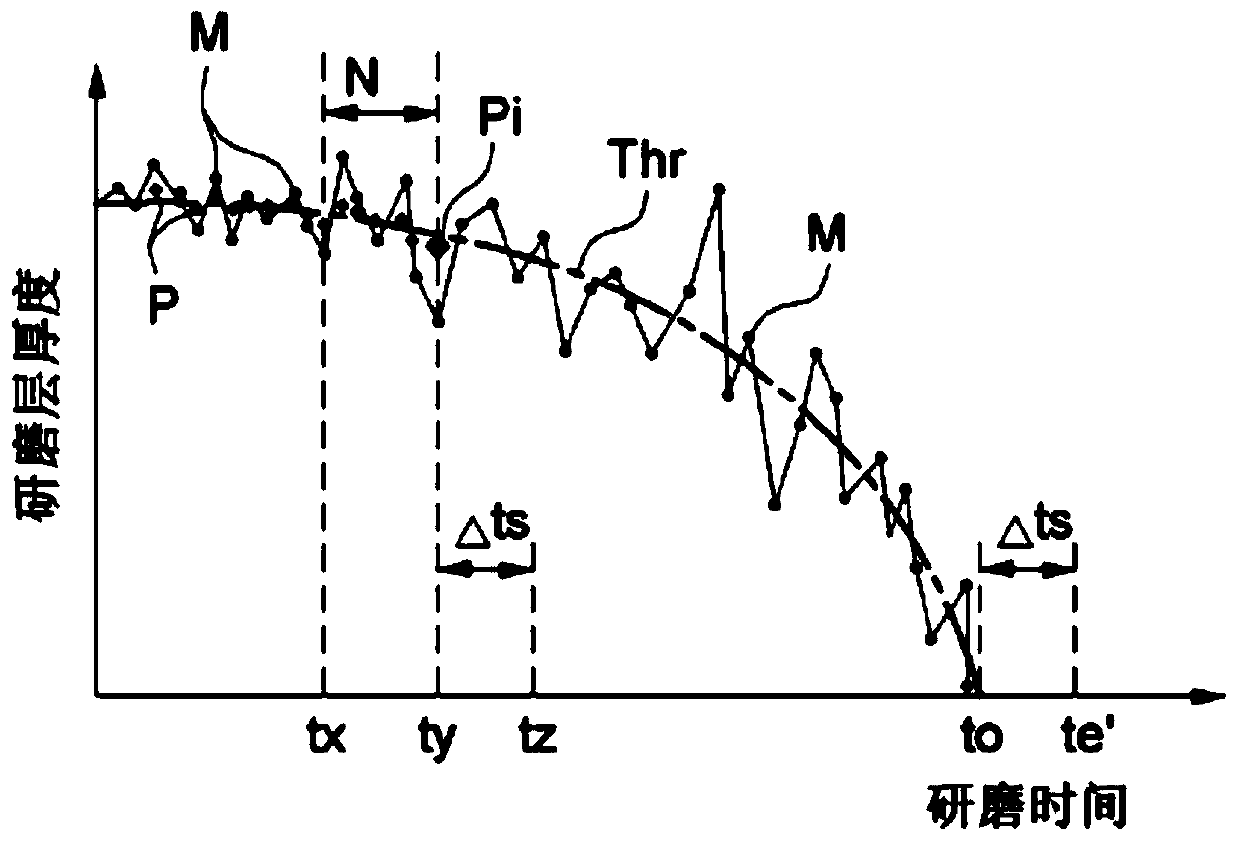

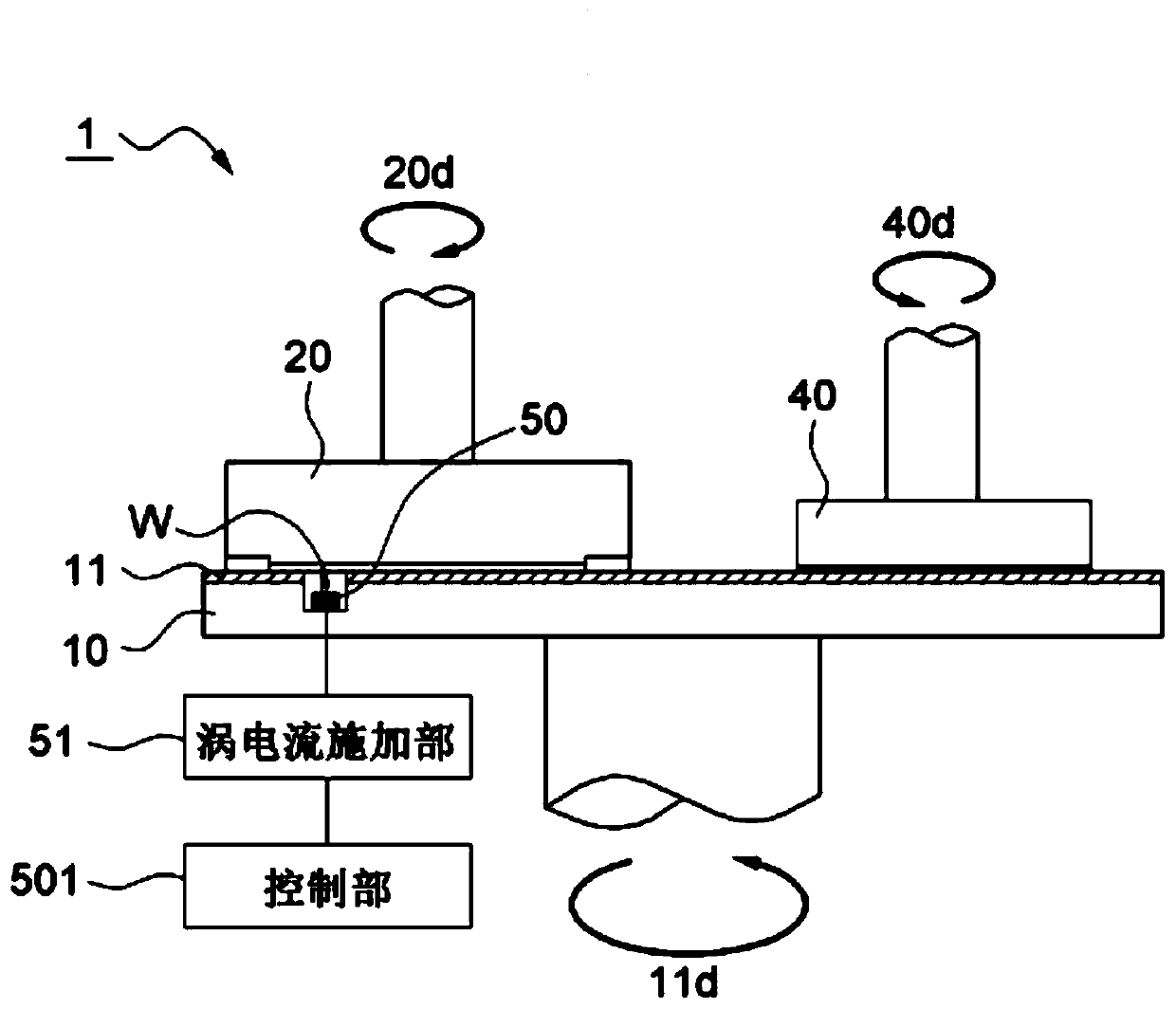

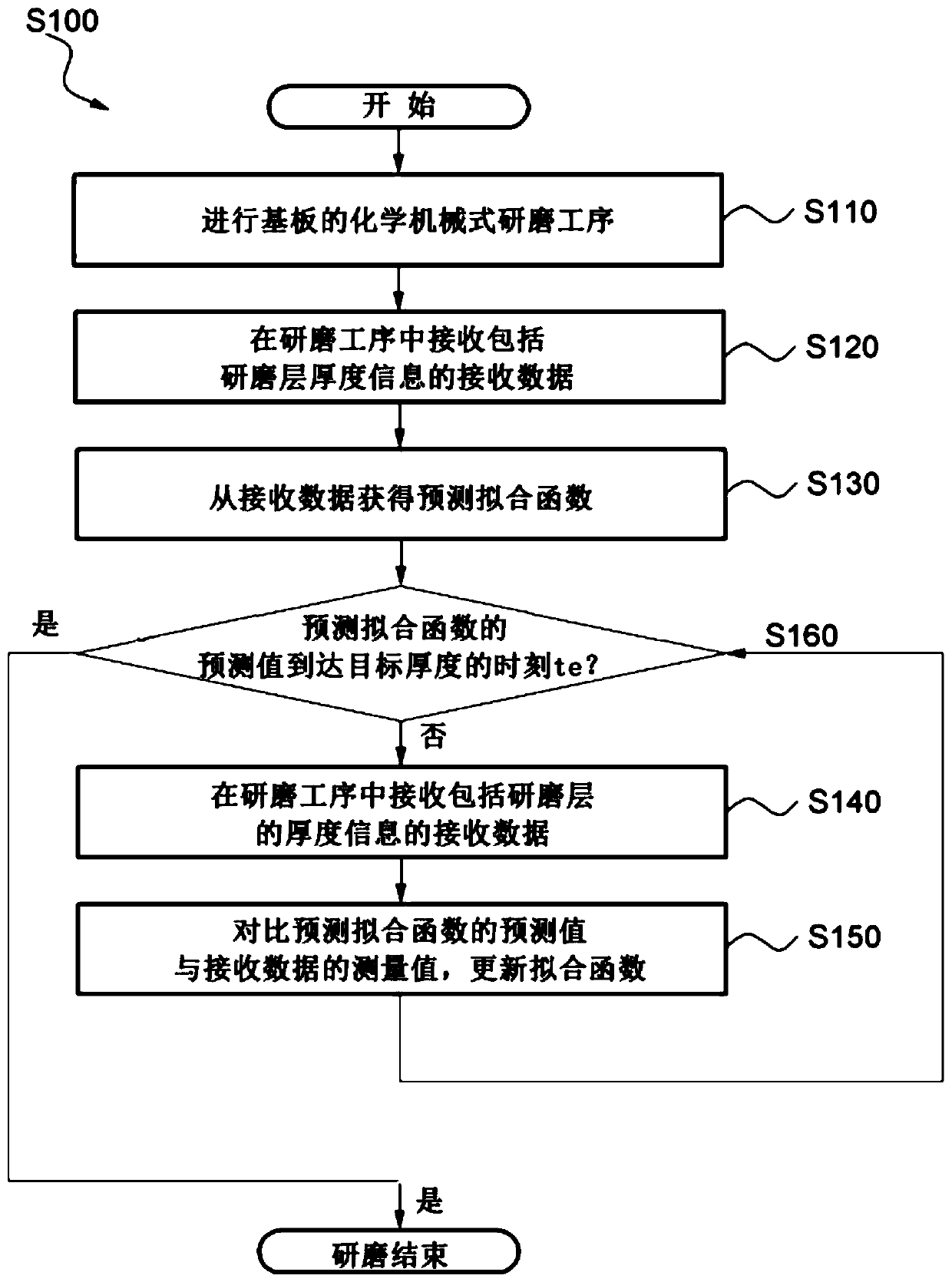

[0039] As shown in the figure, the substrate polishing system 1 of an embodiment of the present invention is used to flatly polish the polishing layer of the substrate W, comprising: a polishing disk 10, which is covered with a polishing pad 11 and rotates 11d; a slurry supply part (not shown) As shown in the figure), it supplies the slurry on the polishing pad 11; the polishing head 20, in the polishing process, pressurizes the substrate W so that the substrate W is located on the lower side; the regulator 40, which rotates 40d in the polishing process And the polishing pad 11 is pressurized and reformed; the slurry supply part (not shown), which supplies slurry to the polishing pad for the chemical fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com