Rotary flume test device for making small debris flow

A technology for rotating a water tank and a test device, which is applied to teaching models, educational appliances, instruments, etc., can solve the problems of small shooting angle, cumbersome structure, troublesome device production, etc., and achieves the effect of large shooting angle, high test accuracy and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

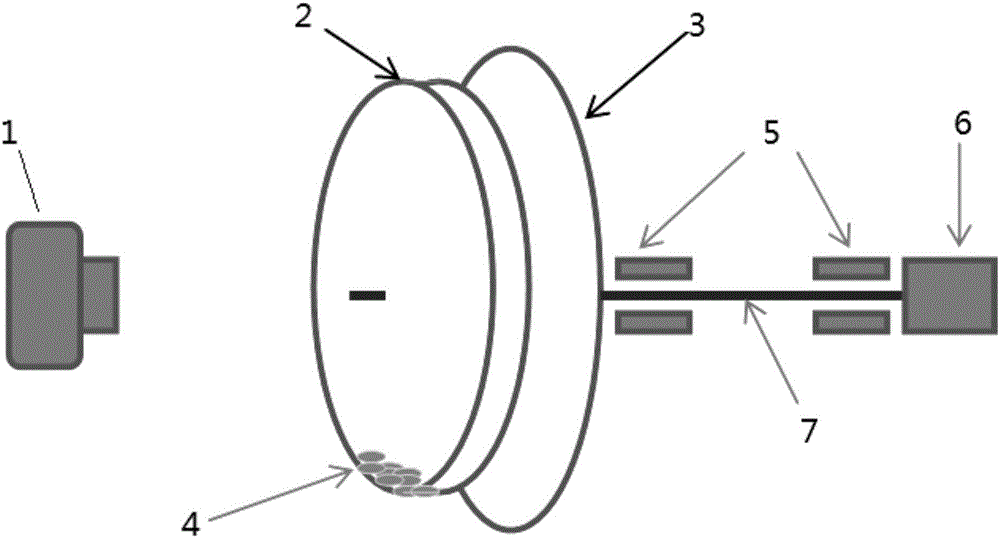

[0030] see image 3 , a rotating water tank test device for making small-scale debris flow, including a rotating water tank 2 made of smooth and transparent material. Structure: An opaque background disk 3 is fixedly arranged behind the rotating water tank 2, and one end of the transmission shaft 7 of the background disk passes through the background disk 3 and is fixedly connected with the axis of the rotating water tank 2, and the other end is connected with the rotating power device 6 A camera 1 is fixedly installed in front of the rotating water tank 2 ;

[0031] see image 3 , There is a smooth arc transition between the bottom surface and the side surface of the rotating water tank 2 .

[0032] see image 3 , the camera 1 is arranged coaxially with the rotating water tank 2, and takes a global picture of the entire front of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com