High-efficiency plastic bottle cap gasket plugging machine

A plastic bottle and lid gasket technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of complicated operation and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

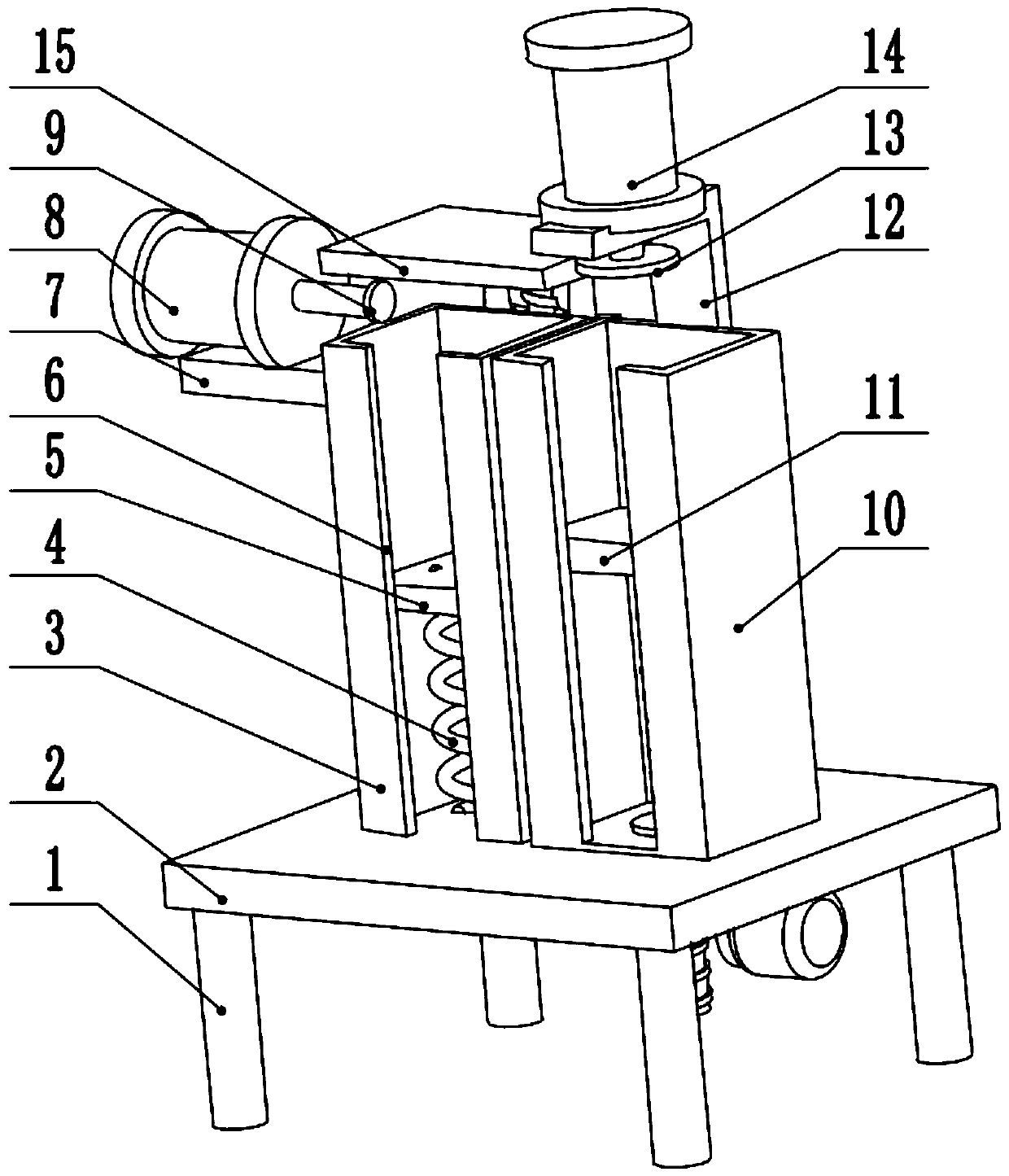

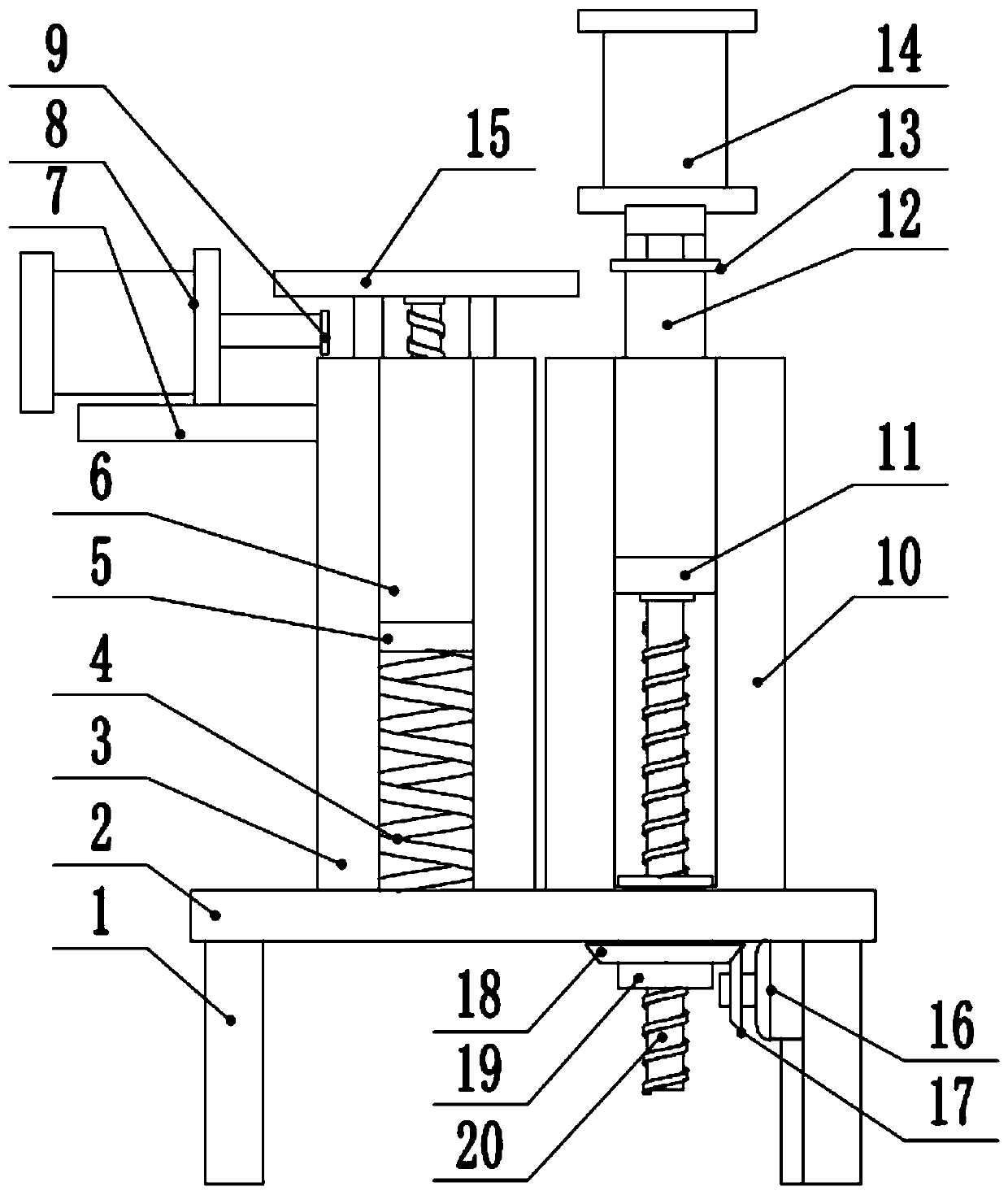

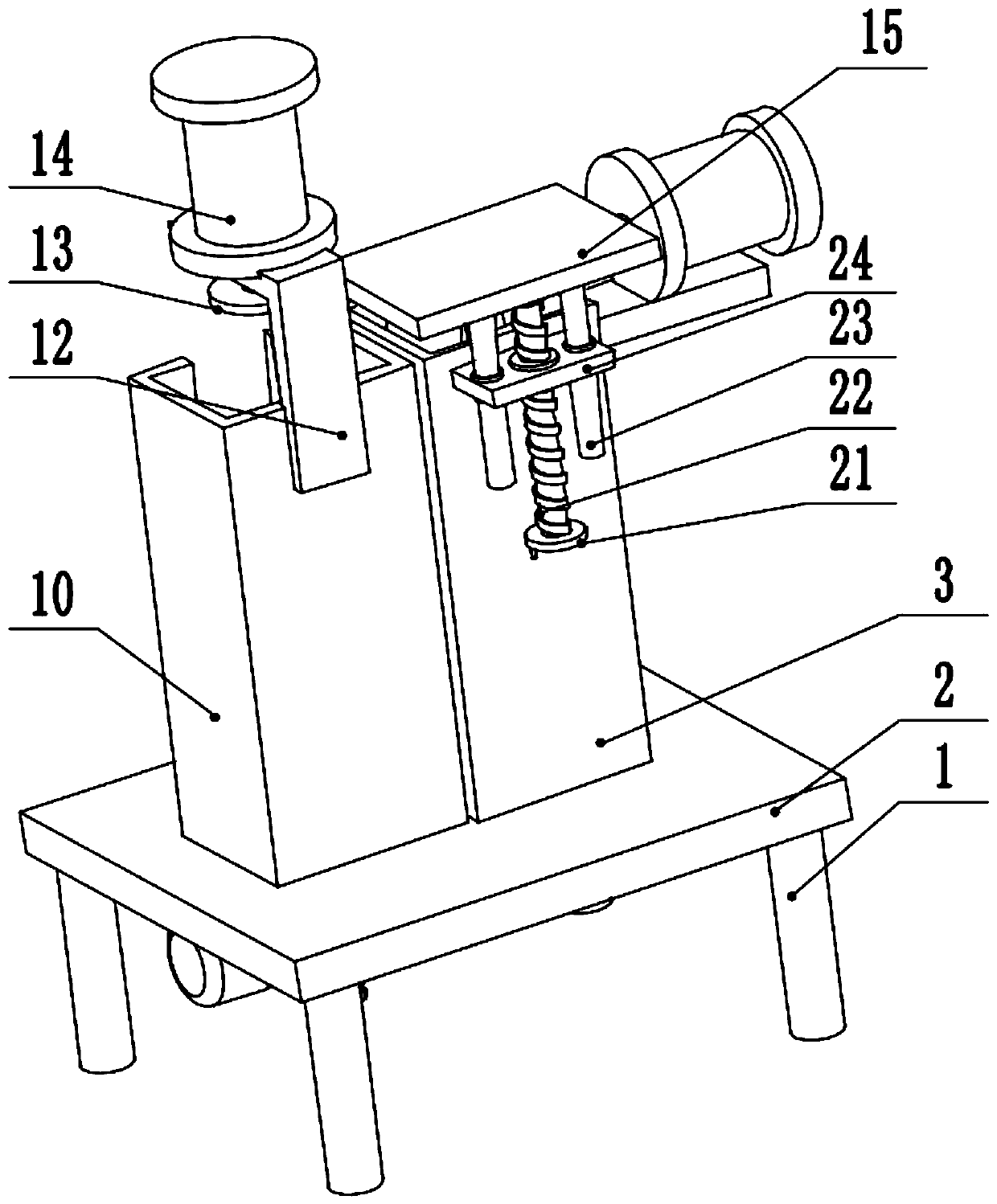

[0023] see Figure 1-3 , a high-efficiency plastic bottle cap gasket plugging machine, including a workbench 2, the lower surface of the workbench 2 is provided with supporting legs 1 on both sides, the upper surface of the workbench 2 is provided with a first storage compartment 3 on the left side, and the workbench The right side of the upper surface of 2 is provided with a second storage bin 10, and the upper rear side of the first storage bin 3 is provided with a second fixing seat 24, and the middle part of the second fixing seat 24 is threadedly connected to the middle part of the second screw mandrel 22, The upper end of the second screw mandrel 22 rotates and connects the baffle plate 15, and the left and right sides of the second holder 24 slide to connect the guide rod 23, and the upper end of the guide rod 23 is fixedly connected to the lower surface of the baffle plate 15, and the lower end of the second screw mandrel 22 is set There is a runner 21, the upper left ...

Embodiment 2

[0026] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, except that: the front sides of the first storage bin 3 and the second storage bin 10 are provided with observation ports 6, for the convenience of understanding the first storage bin 3 and how much raw material there is in the inside of the second placement bin 10, a gap is opened on the front side, thereby as the observation port 6, the capacity of placement can be intuitively observed.

[0027] In the implementation process of the present invention, put gaskets in the first placement bin 3, put the bottle cap in the second placement bin 10, and place the opening of the bottle cap upwards, turn the runner 21, and the runner 21 drives Second screw mandrel 22 rotates, thereby adjusts the height of baffle plate 15, adjusts the height of baffle plate 15 according to the thickness of gasket, makes the spacing between baffle plate 15 and the upper end of first placement bin 3 equal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com