Quantitative flour packaging device

A technology of quantitative packaging and flour, applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of incapable of quantitative packaging, high cost, complex structure, etc., and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

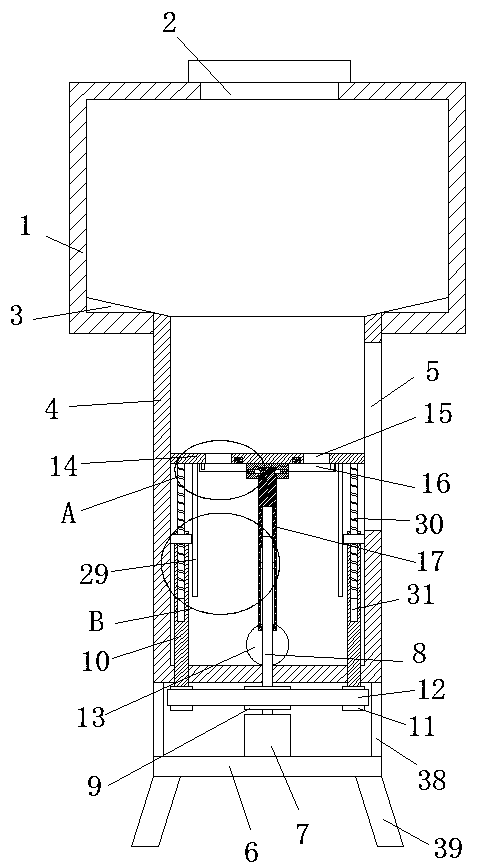

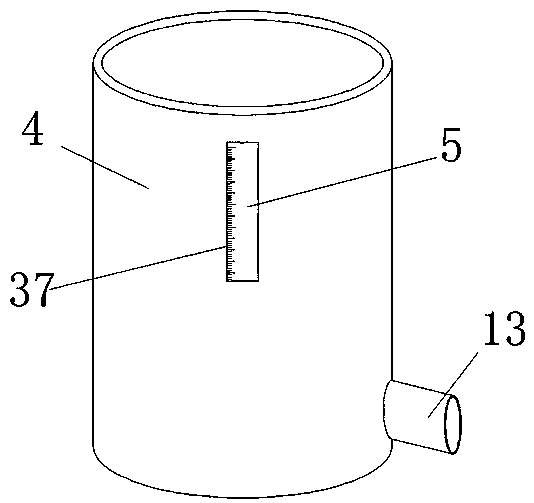

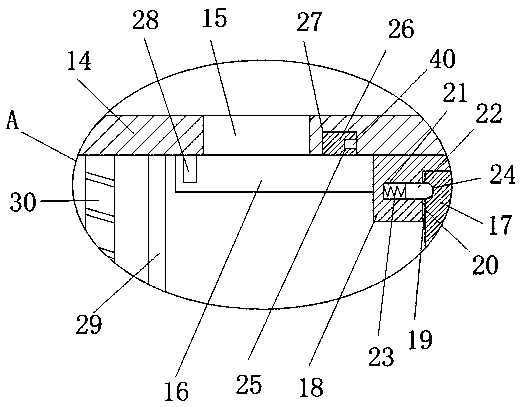

[0028] refer to Figure 1-5 , a flour quantitative packaging device, comprising a flour box 1, the top of the flour box 1 is provided with a feeding port 2, the bottom inner wall of the flour box 1 is provided with an inclined plate 3, the bottom of the flour box 1 is connected with a cylindrical tube 4, and the cylindrical tube A baffle 14 is slidably installed inside the 4, and a transparent plate 5 is arranged on the outside of the cylinder 4, and a scale line 37 is arranged on the transparent plate 5. The position of the baffle plate 14 can be observed through the transparent plate 5 and the scale line 37. There are four blanking holes 15, and the bottom of the baffle plate 14 is rotated with a disc 18, and the outer side of the disc 18 is uniformly fixed with four baffle plates 14, and the four baffle plates 14 are respectively connected to the four blanking holes 15. Adaptation, the bottom of the disc 18 is provided with a support groove 19, the support shaft 17 is rotat...

Embodiment 2

[0039] refer to Figure 1-5, a flour quantitative packaging device, comprising a flour box 1, the top of the flour box 1 is provided with a feeding port 2, the bottom inner wall of the flour box 1 is provided with an inclined plate 3, the bottom of the flour box 1 is connected with a cylindrical tube 4, and the cylindrical tube A baffle 14 is slidably installed inside the 4, and a transparent plate 5 is arranged on the outside of the cylinder 4, and a scale line 37 is arranged on the transparent plate 5. The position of the baffle plate 14 can be observed through the transparent plate 5 and the scale line 37. Four blanking holes 15 are provided, and the bottom of the baffle plate 14 is rotatably equipped with a disc 18, and the outer side of the disc 18 is evenly fixed with four baffle plates 14 by welding, and the four baffle plates 14 are connected with the four blanking holes respectively. 15, the bottom of the disk 18 is provided with a support groove 19, and the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com